Home > No-bake resin sand casting

No-bake resin sand casting

No-bake resin sand casting

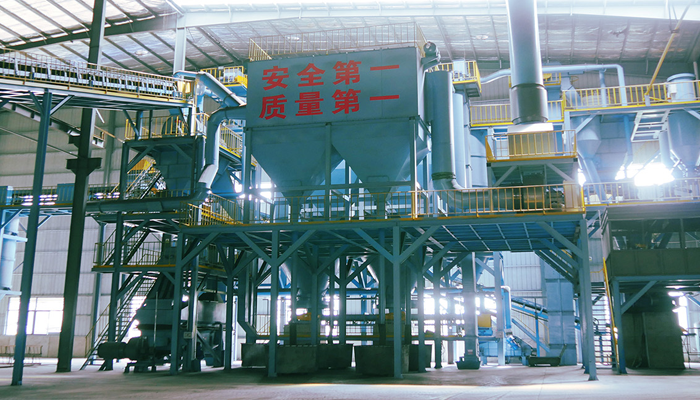

Jiangsu Shengrong Foundry’s resin sand casting is an advanced sand casting process—industry insiders also call it no bake casting, because its sand mold hardens without needing baking. The core of this process is adding synthetic resin as a binder to raw sand (usually silica sand). Through chemical reaction or thermal action, sand grains harden directly in the mold, forming a high-strength, high-precision sand mold. Molten metal is then poured into this mold to create the final casting, ideal for custom iron parts like reducer boxes or agricultural machinery components.

Why choose shengrong resin sand castings?

High Casting Precision & Smooth Surfaces: The sand mold for our no bake casting is strong with minimal deformation, producing castings with sharp outlines, precise dimensions (tolerance up to ±0.05mm), and smooth surfaces that cut down on post-processing work.

High Production Efficiency: A key advantage of resin sand casting is fast mold hardening—no drying steps needed. This shortens production cycles by 30% compared to traditional clay sand casting, perfect for your bulk orders.

Excellent Collapsibility: After casting cooling, the sand mold from our no bake casting easily crumbles, making cleaning faster and reducing labor intensity for your team.

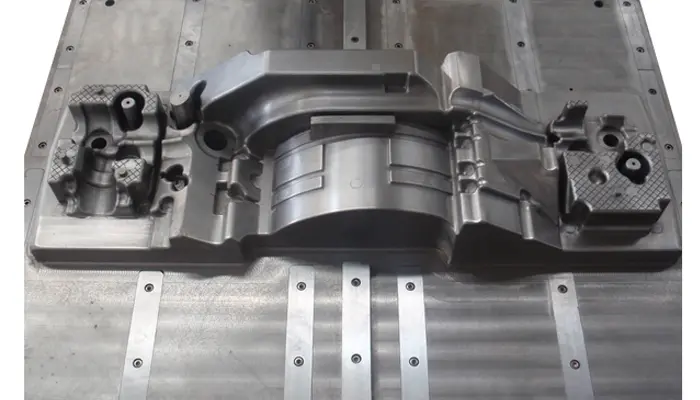

Outstanding Molding Versatility: Resin sand casting (our no bake process) handles very complex shapes, from 1kg small parts to 10000kg large components like robot joints.

Manufacturing Process

Sand Mixing

Precise mixing of raw sand, resin, and hardener is the first step to reliable resin sand casting. We use efficient continuous sand mixers or bowl mixers: first add raw sand and hardener for a brief blend, then add resin. The mix must be used before the resin cures—this “usable time” is a key detail of no bake casting, as expired sand hardens and can’t form quality molds.

Molding & Coremaking

Fill the sand box (with the pattern pre-placed) with the mixed sand for resin sand casting.

Compact the sand via vibration, squeezing, or manual operation—this ensures the mold holds its shape during pouring.

Natural Hardening: Unlike clay sand or water glass sand, our no bake casting mold hardens on its own via the curing agent. No baking or air-blasting is needed; after several to dozens of minutes, it’s strong enough to demold.

Coremaking: Use a core box to create sand cores (for casting internal cavities or complex shapes). These cores match the precision of resin sand casting, with high strength and air permeability.

Mold Assembly

Mold Cleaning: Blow away loose sand from the lower mold cavity—small debris here can cause defects in your resin sand casting parts.

Core Insertion: Accurately place pre-made sand cores into the lower mold cavity at preset positions. This step is critical for ensuring internal structure accuracy in no bake casting.

Upper Mold Closing: Smoothly fit the upper mold to the lower mold, aligning with positioning pins. Misalignment here ruins casting precision, so we take extra care with this step for our resin sand casting service.

Securing the Mold: Molten metal generates strong buoyancy during pouring. We use weights or clamps to fix the mold, preventing leakage and protecting the quality of your no bake casting.

Pouring & Cooling

Pouring: We use molten iron (or other metals) from our 1T/2T induction furnaces (60 tons daily melting capacity)—stable metal quality is the foundation of great resin sand casting. The molten metal is poured smoothly into the mold via a ladle and dedicated pouring system.

Cooling: After pouring, the mold stands until the casting fully solidifies and cools to the right temperature. The sand used in no bake casting has excellent thermal insulation, which helps uniform cooling and reduces internal stress in the final part.

Knockout & Cleaning

Shakeout: After cooling, separate the casting from the sand mold with a vibrating shakeout machine (or manually). A big plus of resin sand casting is its high collapsibility—the sand automatically loosens, making shakeout quick and easy.

Gating/Riser Removal: Remove the gating system and risers via hammering, sawing, or grinding.

Sand Cleaning: Clear residual sand and grit from the casting surface to prepare for finishing.

Grinding: Polish away sprue debris, riser leftovers, and burrs with grinding wheels or polishing machines.

Shot Blasting: Use our shot blasting machine to spray metal pellets, removing surface scale and residual sand—leaving your no bake casting with a smooth, professional finish.

Quality Inspection: Inspect the cleaned casting for dimensions (via CMM), appearance, and non-destructive testing. All our resin sand casting parts meet ISO/IATF16949 standards.