Coated sand core (mold) making process

In recent years, coated sand has been used more and more widely and is used in almost all casting methods. The process methods are different, but whether it is core making or molding, the basic process requirements are (except for wet manual types): heating temperature 200-300℃; curing time 30-150s; sand shooting pressure 0.15-0.6MPa. The specific parameters should be adjusted according to the equipment model, mold, core quality and complexity, type of coated sand, etc. The principle is: simple sand cores, coated sand with good fluidity (or coarse particle size) can choose lower sand shooting pressure, thin sand cores can choose lower heating temperature, and curing time can be appropriately extended when the heating temperature is low; vice versa. The following describes several different application examples.

1. Making solid cores

In theory, coated sand can produce almost all types of solid cores, especially high-precision castings. When using wet coated sand, hot core box equipment and tooling can be used directly to make cores without making any changes to the original equipment and tooling. When using dry coated sand, due to its good fluidity, special treatment is required for the exhaust method of the core box, the nozzle and the core box seal.

2. Making shell molds

Using coated sand to make shell molds is common in casting shaft parts such as camshafts or disc parts such as brake pads and some valve parts with high surface requirements. Its relevant parameters are as follows: sand iron ratio 1: (1.5) ~ 4; draft angle 0.5° ~ 1°, etc., shell wall thickness 8 ~ 12mm.

Uniform shell wall thickness can reduce the amount of coated sand and obtain uniform casting structure. When using coated sand to make shell molds, fixed core shooters or flip core shooters can be used. The former can use dry coated sand or wet coated sand, while the latter can only use dry coated sand.

3. Shell core production

The shell core production with coated sand usually adopts a swing shell core machine (such as K85, K87, K89, etc.), and the core making process is completed through sand shooting, crusting, removing residual sand, curing, and film removal.

In order to ensure the quality of the shell core, in addition to ensuring the quality of the coated sand, it is also necessary to select a reasonable core making process according to the specific conditions of each sand core.

(1) Core box temperature The core box temperature is one of the main factors affecting the thickness of the shell layer. It is generally controlled at 230-300℃ and is selected according to the following principles: ① Ensure sufficient heat required for the softening and curing of the resin on the coated sand; ② Ensure the required shell thickness is formed and the shell core surface is not coked; ③ Try to shorten the crusting and hardening time to improve productivity.

(2) Sand shooting pressure and time The sand shooting pressure should be determined according to the shape and complexity of the sand core, so that the core sand can fill the core box tightly. When the pressure is too high, the sand core is prone to shrinkage and sand leakage; when the pressure is too low, the sand core is prone to looseness. If the sand shooting time is too long, the shell that has been crusted will easily slip, resulting in a very thin shell; if the time is too short, the sand core cannot be formed. The sand shooting pressure is generally 0.15-0.4MPa, and the sand shooting time is generally controlled at 3-10s.

(3) Crusting time The length of the crusting time depends on the thickness of the sand core shell, which is determined by the strength requirements of the sand core during transportation, core assembly and pouring. Under the premise of a certain quality of coated sand, the thicker the shell layer, the higher the strength. When the shell thickness is 6-8mm, the crusting time is 10-30s, and when the shell thickness is 10mm, the crusting time is 20-65s.

(4) Swinging sand dumping time After the shelling stage is completed, the core box sand shooting port is turned downward and swung left and right at an angle of 45o to dump the remaining sand that has not been crusted. This period of time can be determined according to the complexity of the sand core shape and the arrangement of the sand injection port. It is best to pour it clean, generally 5-10s.

(5) Hardening time In order to fully harden the sand shell, the sand core should continue to harden in the heated core box. The hardening time can be determined according to the shell thickness and the core box temperature. If the time is too short, the shell layer is not completely solidified and the strength is lower; if the time is too long, the surface of the sand core is easy to burn. It is generally controlled within 20-100s.

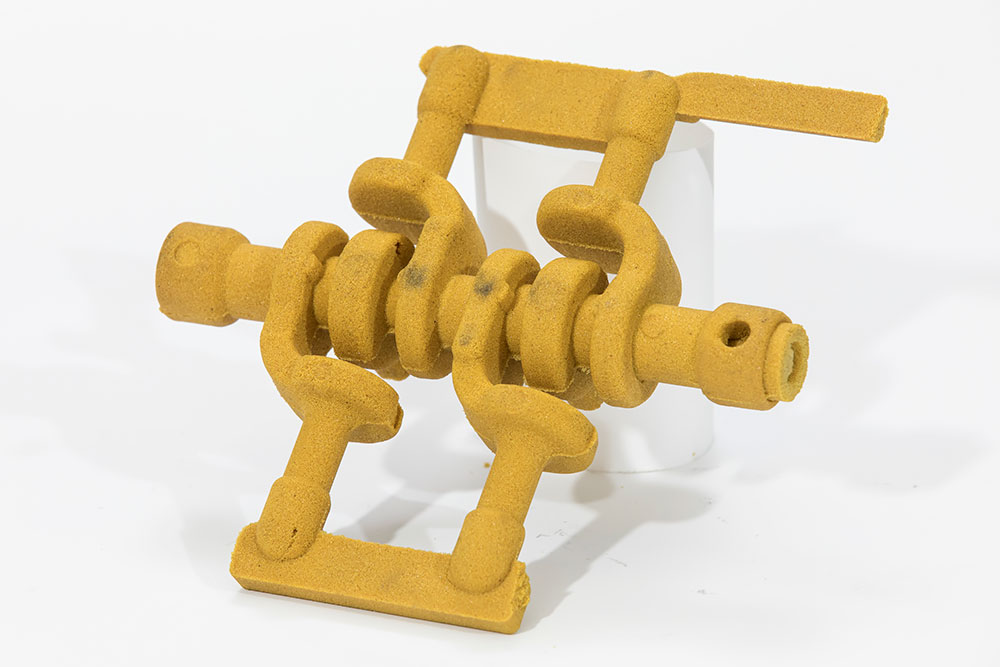

4. Hot centrifugal casting

This process is a traditional centrifugal casting process in a rough-formed metal mold (iron mold). It is mainly used to produce pipe-type rotating body castings. A layer of coating is first applied to the surface of the inner cavity of the iron mold to facilitate mold removal. In recent years, coated sand suitable for centrifugal casting has been developed to replace coating production. Due to its poor exhaust effect, it requires a thin wall (about 3mm), and usually uses double-layer sand, with fine sand (70/140 mesh) on the surface in contact with the casting and coarse sand (50/100 mesh) on the outer layer. 5. Iron mold coated sand process This process is to coat the inner cavity of the roughly formed metal mold (iron mold) with a thin layer of coated sand (3-8mm) to form a cast. It uses various means, such as process tests, computer simulations, and empirical charts, to reasonably set the iron mold wall thickness and coated sand thickness, pouring system and coated sand layer materials, so as to achieve the purpose of filling, solidifying and cooling the cast iron under a relatively favorable condition, and improve its internal quality and surface quality. The average precision of castings produced by iron mold coated sand casting is about CT7 level, and the surface roughness is 12.5um. The main process parameters of iron mold coated sand casting: iron mold wall thickness 25mm, coating sand layer thickness 5-8mm (suitable for small cylinder diameter ductile iron crankshaft); the quality of the iron mold is generally about 5 times the quality of the mold casting; the iron sand ratio (the ratio of the casting quality to the amount of coated sand consumed) is 6-7. There are two methods for sand-coating iron molds (i.e. obtaining the sand coating layer): sand-shooting molding and die-casting molding. The former is currently used more frequently, and the sand coating layer is ordinary coated sand, which is particularly suitable for mass production; the latter is suitable for crankshafts with large single-piece mass (iron mold size up to several meters long), and the sand coating layer is various fluid self-hardening sands. The choice of sand-shooting pressure in the former is related to the thickness of the coated sand. When the sand-shooting pressure is 0.2-0.6MPa and the thickness of the coated sand is 4-5mm, its density is the largest.

Due to the good rigidity of the iron mold, the compactness of the casting can be improved, and the density is increased by an average of 0.86%. Many companies have achieved the cast production of ductile iron crankshafts with four cylinders or less. The cast performance is above QT800-2, and the casting scrap rate is 3% to 5%.