Home > Carbon steel casting parts

Carbon steel casting parts

Carbon steel castings parts as the main alloying element and containing a small amount of other elements. Low carbon steel castings contain less than 0.2% carbon, medium carbon steel castings contain 0.2% to 0.5% carbon, and high carbon steel castings contain more than 0.5% carbon. As the carbon content in steel castings increases, the strength and hardness of steel castings increase. Due to its advantages of high strength, plasticity and toughness, and low cost, many parts used in heavy machinery to bear heavy loads are carbon steel castings.

Carbon steel casting features

1. High strength: Carbon steel castings parts are much stronger than other types of steel, which gives them an advantage in applications that are subject to heavy loads and high stresses. The tensile strength of steel castings can reach 1200 MPa, while the tensile strength of ordinary carbon steel is only 375 MPa.

2.Good toughness: Steel castings have good toughness and can maintain high resistance to deformation even when subjected to impact loads. This makes steel castings advantageous in applications subject to vibration and shock.

3.High wear resistance: Steel castings have a high surface hardness and therefore have good wear resistance. This makes steel castings advantageous in applications subject to wear and friction.

4.Good casting performance: Steel castings have good casting performance, and can be used to produce parts with complex shapes and large sizes through the casting process. This makes steel castings advantageous in the manufacture of large and complex mechanical parts.

5.Low production cost: Compared with other types of steel, the production cost of steel castings is low. This is because the production process of steel castings is relatively simple and does not require complex processing and heat treatment.

6.Good cutting performance: Steel castings have good cutting performance and can be used to produce parts with high precision. This gives steel castings an advantage in manufacturing high-precision parts.

Carbon steel castings Parts

| Carbon steel casting material grade | |||||||||||||

| No. | China | CNS | Japan | South Korea | USA | ISO | Germany | France | Russia aгост |

Sweden SS |

UK | ||

| GB | JIS | KS | AWS | UNS | DIN | W-Nr. | NF | BS | |||||

| 1 | ZG200-400 (ZG15) | SC410 | SC410 (SC42) | SC410 (SC42) | 415-205 (60-30) | J03000 | 200-400 | GS-38 | 1.0416 | – | 15л | 1306 | – |

| 2 | ZG230-450 (ZG25) | SC450 | SC450 (SC46) | SC450 (SC46) | 450-240 965-35) | J03101 | 230-450 | GS-45 | 1.0446 | GE230 | 25л | 1305 | A1 |

| 3 | ZG270-500 (ZG35) | SC480 | SC480 (SC49) | SC480 (SC49) | 485-275 (70-40) | J02501 | 270-480 | GS-52 | 1.0552 | GE280 | 35л | 1505 | A2 |

| 4 | ZG310-570 (ZG45) | SCC5 | SCC5 | SCC5 | (80-40) | J05002 | – | GS-60 | 1.0558 | GE320 | 45л | 1606 | – |

| 5 | ZG340-640 (ZG55) | – | – | – | – | J05000 | 340-550 | – | – | GE370 | – | – | A5 |

Sand casting process and equipment

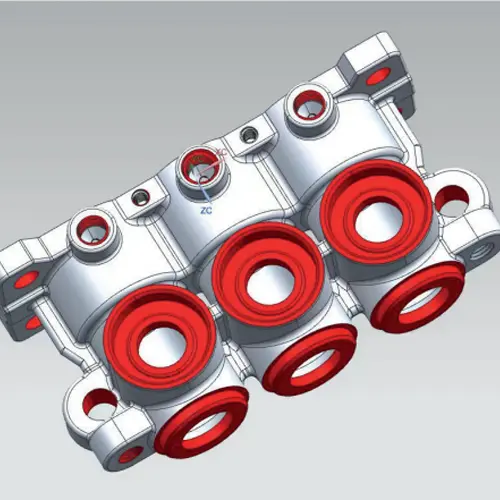

Design and produce molds

We have established an engineering technology materials R&D center to invest more in product development and technological innovation. In line with the CAD and UG three-dimensional mold creation capabilities equipped with independent R&D, we can reduce design defects, improve casting quality, and improve product processing and casting methods, technologies and The improvements and innovations in the process have made Shengrong a complete solution provider in the high-end casting industry that integrates R&D and production.

Cast Star Horizontal Molding Line

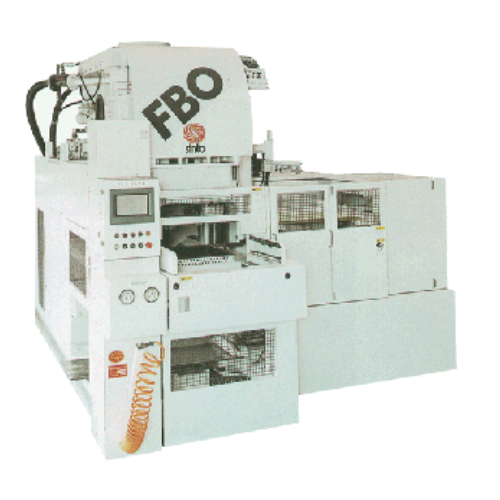

Sinto Molding Machine

Coremaking machine

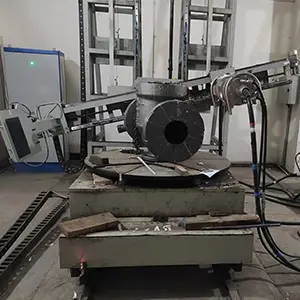

Melting and pouring

1T intermediate frequency furnace 3 sets.

Cleaning and heat treatment

Heat treatment furnaces

Machining centers

20 machining centers for casting parts

Inspetion and testing of casting parts

we have independent physical and chemical testing laboratory. The main testing equipment includes: 2 spectrometers, 2 universal material testing machines, C-S analyzer, Si-Mn-P high-speed analyzer, 2 metallographic microscopes, 2 Brinell hardness meters, impact testing machines, molding sand permeability detectors, independent physical and chemical testing laboratory,air permeability tester for molding sand, tensile tester for molding sand, high-frequency infrared moisture detector, ultrasonic flaw detector and various equipment. Sand tensile test detector, high-frequency infrared moisture detector, ultrasonic flaw detector and all kinds of equipment are complete.

Spectrometer

Carbon sulfur analyzer

Impact tester

Metallurgical microscope

Radial inspection machine

Hydraulic universal testing machine

The production of carbon steel casting parts

1: What casting process you offer?

We use sand casting, lost foam casting, resin sand casting and other process

2: What size of the parts you are making?

We make the parts from 0.5kgs to 10000kgs, special size is available

3: What the lead time of production?

For samples, it need about 30days(model develop time 15-20 days, samples production time 10 days)

Bulk order after mold finished, it need about 20 days

4: What capacity do you have?

Our yearly production can reach to 4000 tons

5:Can you do the machining as our drawing?

Yes, please offer detailed 2D drawing

6: What about your after service?

We promise the QC pass rate 95%, if lower than this, we will send you new part free of charge