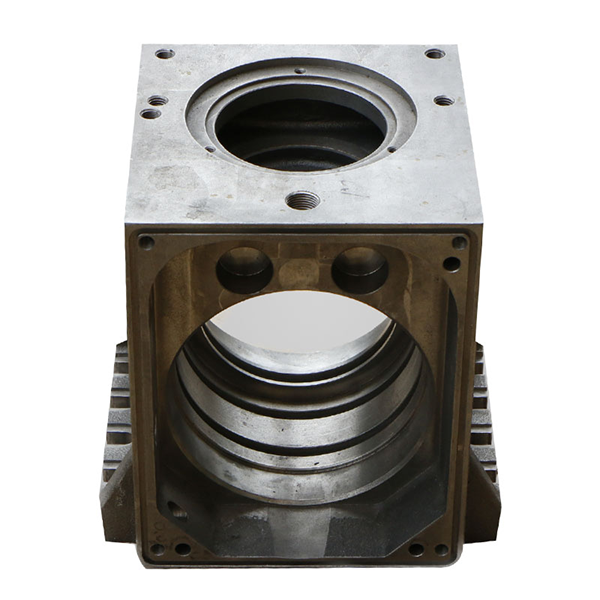

Jiangsu Shengrong produces a variety of housing castings made of gray iron and ductile iron. These include valve housings, pump housing,reducer housings, hydraulic valve block cast iron housings, robot reducer housings, new energy vehicle motor end caps, gearbox housings, PLC control cabinet housings, and high-pressure valve housings. Our products are highly wear-resistant and strong, earning praise from our customers.

Name: housing casting

Material: Ductile cast iron/QT400-10/GGG40/QT450-10/GGG45

Standard/tollerance: EN1561-2011/GB/T 9439/GB/T 1348

Size and weight: OEM by drawing

1. Excellent Mechanical Properties

High Strength and Wear Resistance: Cast iron (especially ductile iron) has high tensile strength and hardness, capable of withstanding heavy loads and frequent friction, making it suitable for high-stress environments such as construction machinery and machine tools.

Good Compressive Resistance: Cast iron's compressive strength exceeds that of many metals, making it suitable for applications requiring structural support (such as equipment bases and heavy machinery casings).

2. Excellent Vibration and Damping Properties

The microstructure of cast iron (such as graphite flakes or spherical graphite) effectively absorbs vibration energy, reducing resonance and noise during operation. It is particularly suitable for applications requiring high stability, such as precision machine tools and engine blocks.

3. High-Temperature Resistance and Thermal Stability: Cast iron has a low coefficient of thermal expansion, minimizes deformation at high temperatures, and resists thermal fatigue (for example, gray cast iron HT250 can be used in high-temperature environments). It is commonly used in heat-resistant components such as internal combustion engines and brake discs.

Industrial: Machine tool beds, gearboxes, hydraulic press frames.

Automotive: Engine blocks, transmission housings, brake components.

Infrastructure: Pipeline manhole covers, power distribution boxes.

Appliances/Tools: Traditional sewing machine bases, heavy-duty tool housings.

Material Type:

Gray cast iron (HT150, HT200, HT250, conforming to GB/T 9439 or ASTM A48)

Ductile cast iron (QT400-15, QT450-10, conforming to GB/T 1348 or ASTM A536)

Dimension Range:

OD/ID: 50mm-3000mm (customizable depending on application)

Wall thickness: 5mm-50mm (depending on pressure requirements)

Length/Height: Determined by design requirements.

Pressure Rating:

Low pressure (under 0.6MPa), medium pressure (1.0-2.5MPa), high pressure (requires special design).

Surface Treatment:

Paint, galvanizing, blackening, or anti-rust oil coating.

Pressure Requirements:

Surface roughness (Ra1.6-Ra6.3), geometric and positional tolerances (e.g., flatness, concentricity).

1. Excellent Mechanical Properties

High Strength and Wear Resistance: Cast iron (especially ductile iron) has high tensile strength and hardness, capable of withstanding heavy loads and frequent friction, making it suitable for high-stress environments such as construction machinery and machine tools.

Good Compressive Resistance: Cast iron's compressive strength exceeds that of many metals, making it suitable for applications requiring structural support (such as equipment bases and heavy machinery casings).

2. Excellent Vibration and Damping Properties

The microstructure of cast iron (such as graphite flakes or spherical graphite) effectively absorbs vibration energy, reducing resonance and noise during operation. It is particularly suitable for applications requiring high stability, such as precision machine tools and engine blocks.

3. High-Temperature Resistance and Thermal Stability: Cast iron has a low coefficient of thermal expansion, minimizes deformation at high temperatures, and resists thermal fatigue (for example, gray cast iron HT250 can be used in high-temperature environments). It is commonly used in heat-resistant components such as internal combustion engines and brake discs.

Industrial: Machine tool beds, gearboxes, hydraulic press frames.

Automotive: Engine blocks, transmission housings, brake components.

Infrastructure: Pipeline manhole covers, power distribution boxes.

Appliances/Tools: Traditional sewing machine bases, heavy-duty tool housings.

Material Type:

Gray cast iron (HT150, HT200, HT250, conforming to GB/T 9439 or ASTM A48)

Ductile cast iron (QT400-15, QT450-10, conforming to GB/T 1348 or ASTM A536)

Dimension Range:

OD/ID: 50mm-3000mm (customizable depending on application)

Wall thickness: 5mm-50mm (depending on pressure requirements)

Length/Height: Determined by design requirements.

Pressure Rating:

Low pressure (under 0.6MPa), medium pressure (1.0-2.5MPa), high pressure (requires special design).

Surface Treatment:

Paint, galvanizing, blackening, or anti-rust oil coating.

Pressure Requirements:

Surface roughness (Ra1.6-Ra6.3), geometric and positional tolerances (e.g., flatness, concentricity).

1. Process Design Phase

Modeling is performed using CAD software based on the drawings. CAE simulations are then used to simulate the mold filling and solidification processes. The gating system, riser, and chiller layout are optimized to minimize defects such as shrinkage cavities and air holes.

Mold/Pattern Production

Sand Casting: Craft wooden or metal molds (for molding).

Die Casting/Metal Mold Casting: Craft steel molds, taking into account shrinkage and surface finish.

Lost Foam Casting: Craft solid models using foam plastic.

2. Molding and Core Making

Molding Sand Preparation: Quartz sand + binder (clay, resin, etc.) must be controlled for strength and air permeability.

Molding: Upper and lower sand molds are created manually or by machine (vibration compression or injection molding). Complex structures require core positioning.

Die Casting: Molten metal is injected into a steel mold under high pressure. Suitable for thin-walled shells.

Investment Casting: Apply wax to the mold, create the shell, and then dewax. Suitable for high-precision, complex parts.

3. Melting and Pouring

Cast Iron: Use a cupola or electric furnace to control carbon equivalent, sulfur, and phosphorus content. Aluminum casting: Melting in a resistance furnace requires refining and degassing (using argon or adding a solvent).

Temperature control: Cast iron 1200-1400°C, aluminum alloy 680-750°C.

Speed control: Avoid turbulence that can cause slag inclusions or porosity.

4. Cooling and cleaning

Cooling: Natural cooling or controlled cooling rate (to prevent stress cracks).

Sand shakeout: A vibrating shakeout machine removes the molding sand and reduces the casting temperature to below 200°C.

Remove the riser (gas cutting or sawing).

Shot blasting/shot blasting removes surface sand.

Grind away flash and burrs.

Raw material control

Use a spectrometer to monitor the melting composition (C, Si, Mn, P, S, etc.) in real time to ensure compliance with standards (such as HT250: C 3.0-3.3%, Si 1.8-2.2%).

Ductile iron needs to control the residual Mg (0.03-0.06%) and rare earth elements.Deoxidation: Add aluminum or silicon-calcium alloy to reduce pores.

Spheroidizing: Ductile iron uses the punching method or wire feeding method (spheroidizing rate ≥ 90%).Mold accuracy: 3D simulation optimization of the pouring and riser system (ProCAST/Magma software), the parting surface misalignment is ≤ 0.2mm.Resin sand: tensile strength ≥ 1.2MPa, moisture ≤ 4%.

Lost foam: EPS beads pre-expanded density 0.018-0.022g/cm³.Temperature control:Gray cast iron 1300-1400Ductile cast iron 1350-1420 15-25Pouring flow rate control 0.5-1.0kg/s.Porosity: Moulding sand air permeability ≥80, vacuum before pouring (lost foam).Shrinkage: Add chilled iron to thick wall, riser volume ≥30% of shrinkage compensation area.

Sand casting:

Resin sand: high precision, suitable for small batches of complex parts.

Coated sand: smooth surface, suitable for thin-walled valve bodies.

Used for high-precision, small-size valve bodies to reduce subsequent processing.

During sand casting, the core must be accurately positioned (such as the flow channel) to prevent eccentricity.

Smelting and pouring: strictly control the temperature (1300-1400℃ for cast iron, 1500-1600℃ for cast steel) to avoid oxidation and slag inclusion.

Cooling and cleaning: slow cooling to reduce stress, and remove the pouring head after vibrating the sand.

Heat treatment: annealing or normalizing to eliminate internal stress, ductile iron needs spheroidization.

Key process requirements

(1) Rough machining:Remove the excess quickly and reserve 0.3-0.5mm for finishing.

Equipment: Vertical/horizontal machining center (such as DMG MORI), gantry milling machine.

Use large diameter face milling cutter (φ80-120mm) to process large planes, cutting parameters:

Cast iron: cutting speed 120-180m/min, feed 0.1-0.2mm/tooth..

(2) Semi-finishing

Correct rough machining deformation and improve dimensional consistency.

(3) Finishing:Core requirements:

Valve hole accuracy: IT7 level (diameter tolerance ±0.015mm), cylindricity ≤0.01mm.

Surface roughness: Ra0.8-1.6μm (sealing surface requires Ra0.4μm).

Typical process:

Use diamond or CBN boring tool, micro cutting (cutting depth 0.05-0.1mm).

Cast iron valve hole fine boring parameters: speed 1500-2000rpm, feed 0.05-0.1mm/rev.

Valve seat grinding:

Use ball end milling cutter or special grinding head to process conical sealing belt (such as 60° cone angle).

X-ray inspection: detect internal shrinkage holes and cracks (in accordance with ASTM E802 standard).

Ultrasonic testing: used when the wall thickness is ≥20mm.

Pressure test: 1.5 times the working pressure for 5 minutes without leakage. The coordinate measuring machine (CMM) detects the hole distance (±0.02mm) and coaxiality (φ0.03mm).

The pneumatic measuring instrument measures the valve hole diameter (resolution 0.001mm).

The valve core is assembled simulated to test the switching resistance and leakage (such as ≤10mL/min).

1: Advanced technology and equipment standards

Advanced technology: Sand casting, precision casting, and lost foam casting process. Casting sizes according to customer requirements, weights ranging from 0.5kg to 10,000kg

Automation equipment: Equipped with automated production lines, intelligent melting furnaces (medium frequency/high frequency induction furnaces),

Inspection equipment: Chemical composition/spectrometer and mechanical property inspection equipment, three-coordinate measuring machine (CMM), X-ray flaw detector, spectrometer, ultrasonic testing and other high-end quality inspection methods.

2:Quality management system

ISO 9001 (quality management system)

IATF 16949 (automotive industry quality management system, such as automotive parts)

ASTM/EN/JIS and other international material standards.

3:Customization capability

Customized production according to customer drawings, customers only need to pay half of the mold fee to develop new castings. The mold time is short, only 20 days, and the casting time only 10 days. Machining 10 days.

Free express sample to customers, mass production after customer samples are confirmed to be fully qualified. Our company does not require customers to place a minimum order quantity, satisfying customers with a variety of choices

4:Competitive prices

Our company’s prices are very competitive in the industry, and the specific price depends on the casting drawing and the customer’s order quantity. Welcome to inquire

Carbon, silicon, manganese, sulfur, phosphorus, chromium, nickel, copper and other elements

Tensile strength, yield strength, elongation, hardness, impact strength

Three-coordinate inspection, non-destructive testing, pressure testing, etc.

Every parts we will use anti-rust oil packing or primer, keep every parts in good condition after long time shipping.For small parts, we use wood box pallet packing.For bigger parts with pallet packing

Jiangsu Shengrong High end Equipment Manufacturing Industry Co., Ltd is a professional iron casting foundry about 26,000 square meters, Investment of 80 million yuan,include intermediate frequency furnace, new east Seoul horizontal line, cast star horizontal line, micro crystal automatic casting machine, 40T mixer and 20T mixer, core-making machine, shot blasting machine, machining center, inclined rail lathe, slot machine, vertical lathe, flat rail lathe and other equipment.Testing equipment:spectrometer, tensile testing machine, hardness tester, etc., and supporting chemical testing laboratories. Mainly engaged in: mechanical parts, auto parts, industrial pump parts, bearings and transmission parts manufacturing. Company’s main business: QT450-12, 500-7, 600-3 ball mill castings and HT250, HT300 gray iron castings and cast steel, stainless steel and other business, with the increase of business volume, the production is not only to meet the main business, while the product after the process of product processing business development, so that enterprises diversified production. Now the company has more than 100 employees, including a professional management team and new product development.

CONTACT

Get In Touch