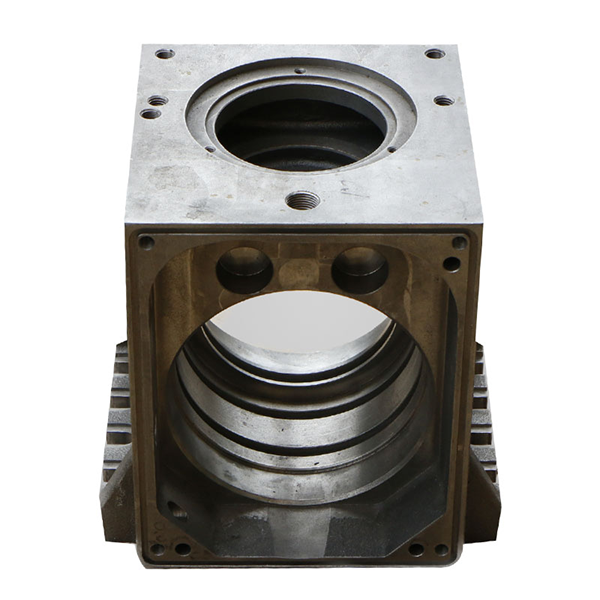

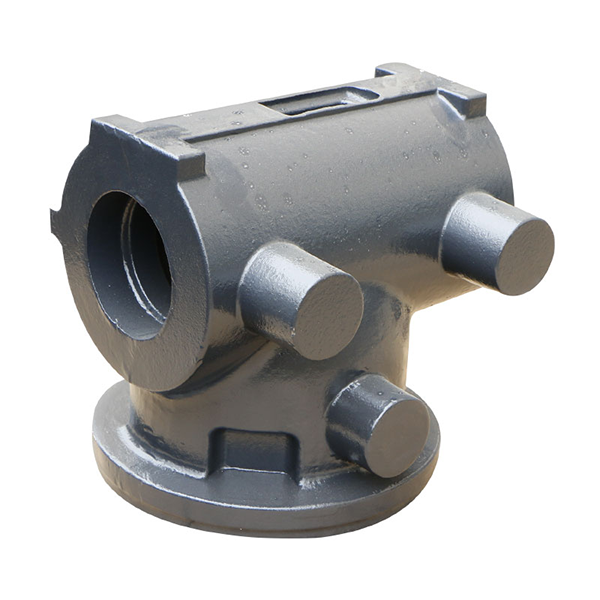

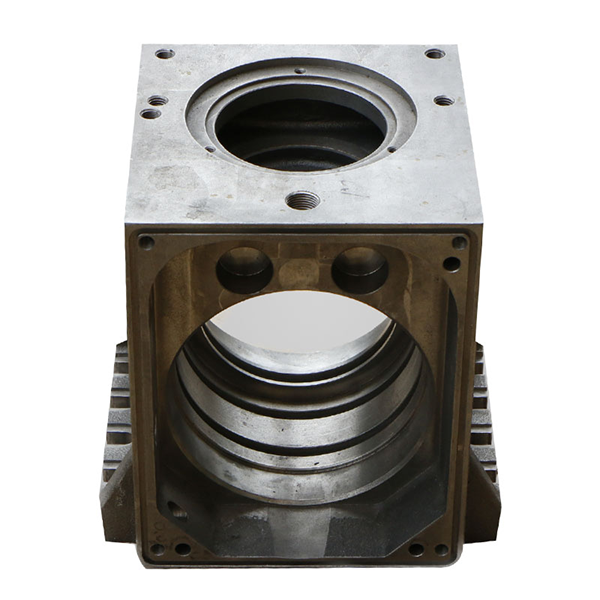

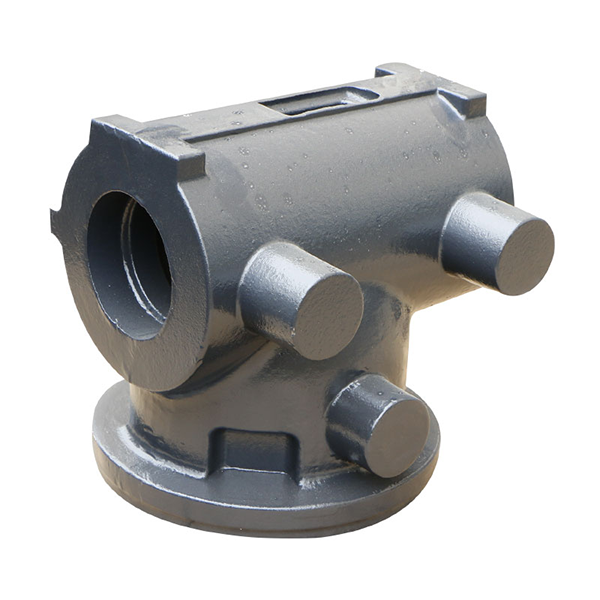

Base casting is a common industrial component, used to support mechanical equipment, instruments or other structures. Our casting foundry products has high wear resistance and strength, have Long service life. Our base casting parts are of high precision, wear resistance, low price and fast delivery.

Material: gray cast iron

Material: Cast iron HT250/GG25

Standard/tollerance: EN1561-2011/GB/T 9439/GB/T 1348

Size and weight: According to drawing

1. Exceptional Strength & Durability

Our base castings are constructed of high quality gray and ductile iron (GG25, GG30), with excellent compressive strength and impact resistance that withstands heavy loads and severe operating conditions. For instance, our GG30 cast iron base offers tensile strength ≥300 MPa and hardness 190-245 HB for stability over the long term with zero deformation.

2. Complex Geometry Adaptability

The machinery bases have intricately shaped castings that allow internal support ribs and integrated channels that would be difficult to fabricate or weld, which lowers stress points and potential weak areas.

3. Cost-Effectiveness for Volume Production

For these like a base casting high-volume projects, the mold costs are amortized out and per part cost is diminished. Plus our in-house CNC machining eliminates secondary vendors and provides ease of production when designing custom base castings.

4. Superior Vibration Damping & Noise Reduction

The graphite microstructures on our cast iron bases 6-10 times absorb vibrations and noise than steel for stability that lasts Built For The Trade: The graphite microstructure in the cast iron base is crucial for elite machinery equipment such as machine tools, industrial air compressors and generators.

5. Enhanced Corrosion & Wear Resistance

For our base plates we provide a range of surface treatments, including Anti-Rust Painting, Galvanization or Epoxy Coating to protect against the effects of corrosive environments (e.g. chemical and marine) extending service life considerably.

6. Production Flexibility & Scalability

Our industrial base castings range from 1 kg to 10,000 kg and we support this wide range with our daily melting capacities of 60 tons, and sand processing capacity of up to 400 tons, providing consistency not only for high volume foundry castings orders but also custom foundation castings.

1. Industrial Machinery and Machine Tools

Applications: Machine tool beds, columns, and worktable bases.

The high damping properties of cast iron (such as gray cast iron HT250) reduce cutting vibration and improve machining accuracy.

2. Energy and Power Equipment

Applications: Wind turbine tower bases (cast steel).

Steam turbine and hydro turbine support bases.

Transformer housings and mounting bases (cast iron).

3. Heavy Machinery and Engineering Equipment

Applications: Excavator and crane chassis and slewing bearing bases.

Hydraulic press and stamping press bodies (such as ductile iron QT500-7).

4. Transportation

Applications: Railway locomotive bogie components and track mounting bases.

Marine engine bases (cast iron or cast steel).

Truck transmission brackets.

5. Chemical and Petroleum Equipment

Applications: Pump and valve housings and mounting bases (such as stainless steel casting CF8M).

Reactor support frames. 6. Construction and Infrastructure

Applications: Counterweight bases for large construction machinery (such as tower cranes).

Bridge supports and foundations for earthquake-resistant structures.

7. Automation and Robotics

Applications: Industrial robot bases (such as aluminum alloy die-casting for lightweighting).

Conveyor belt supports for automated production lines.

1. Material Selection

Cast Iron (Common):

Gray Cast Iron (HT150/HT200): Suitable for general loads, low cost, and good wear resistance.

Ductile Cast Iron (QT400/QT500): High strength and impact resistance, suitable for heavy or dynamic loads.

Cast Steel (such as ZG230-450): Used in applications requiring high strength and toughness.

Aluminum Alloy: Suitable for lightweighting, but with lower load-bearing capacity.

2. Dimensions and Tolerances

Basic Dimensions: Determine the length, width, height, and critical mounting hole dimensions based on the design drawings.

Tolerance Standards:

Tolerances for unmarked dimensions refer to GB/T 6414 (casting tolerance grades CT7-CT9).

Critical mating surfaces require individual tolerances (such as IT8-IT10).

Geometric Tolerances: Flatness, parallelism, and perpendicularity (such as GB/T 1182).

1. Exceptional Strength & Durability

Our base castings are constructed of high quality gray and ductile iron (GG25, GG30), with excellent compressive strength and impact resistance that withstands heavy loads and severe operating conditions. For instance, our GG30 cast iron base offers tensile strength ≥300 MPa and hardness 190-245 HB for stability over the long term with zero deformation.

2. Complex Geometry Adaptability

The machinery bases have intricately shaped castings that allow internal support ribs and integrated channels that would be difficult to fabricate or weld, which lowers stress points and potential weak areas.

3. Cost-Effectiveness for Volume Production

For these like a base casting high-volume projects, the mold costs are amortized out and per part cost is diminished. Plus our in-house CNC machining eliminates secondary vendors and provides ease of production when designing custom base castings.

4. Superior Vibration Damping & Noise Reduction

The graphite microstructures on our cast iron bases 6-10 times absorb vibrations and noise than steel for stability that lasts Built For The Trade: The graphite microstructure in the cast iron base is crucial for elite machinery equipment such as machine tools, industrial air compressors and generators.

5. Enhanced Corrosion & Wear Resistance

For our base plates we provide a range of surface treatments, including Anti-Rust Painting, Galvanization or Epoxy Coating to protect against the effects of corrosive environments (e.g. chemical and marine) extending service life considerably.

6. Production Flexibility & Scalability

Our industrial base castings range from 1 kg to 10,000 kg and we support this wide range with our daily melting capacities of 60 tons, and sand processing capacity of up to 400 tons, providing consistency not only for high volume foundry castings orders but also custom foundation castings.

1. Industrial Machinery and Machine Tools

Applications: Machine tool beds, columns, and worktable bases.

The high damping properties of cast iron (such as gray cast iron HT250) reduce cutting vibration and improve machining accuracy.

2. Energy and Power Equipment

Applications: Wind turbine tower bases (cast steel).

Steam turbine and hydro turbine support bases.

Transformer housings and mounting bases (cast iron).

3. Heavy Machinery and Engineering Equipment

Applications: Excavator and crane chassis and slewing bearing bases.

Hydraulic press and stamping press bodies (such as ductile iron QT500-7).

4. Transportation

Applications: Railway locomotive bogie components and track mounting bases.

Marine engine bases (cast iron or cast steel).

Truck transmission brackets.

5. Chemical and Petroleum Equipment

Applications: Pump and valve housings and mounting bases (such as stainless steel casting CF8M).

Reactor support frames. 6. Construction and Infrastructure

Applications: Counterweight bases for large construction machinery (such as tower cranes).

Bridge supports and foundations for earthquake-resistant structures.

7. Automation and Robotics

Applications: Industrial robot bases (such as aluminum alloy die-casting for lightweighting).

Conveyor belt supports for automated production lines.

1. Material Selection

Cast Iron (Common):

Gray Cast Iron (HT150/HT200): Suitable for general loads, low cost, and good wear resistance.

Ductile Cast Iron (QT400/QT500): High strength and impact resistance, suitable for heavy or dynamic loads.

Cast Steel (such as ZG230-450): Used in applications requiring high strength and toughness.

Aluminum Alloy: Suitable for lightweighting, but with lower load-bearing capacity.

2. Dimensions and Tolerances

Basic Dimensions: Determine the length, width, height, and critical mounting hole dimensions based on the design drawings.

Tolerance Standards:

Tolerances for unmarked dimensions refer to GB/T 6414 (casting tolerance grades CT7-CT9).

Critical mating surfaces require individual tolerances (such as IT8-IT10).

Geometric Tolerances: Flatness, parallelism, and perpendicularity (such as GB/T 1182).

1. Design and Process Planning

Requirements Analysis: Define the base casting's purpose, load-bearing requirements, and operating environment (e.g., high-temperature resistance, corrosion resistance, etc.).

3D Modeling: Use CAD software to design casting drawings and determine dimensions, tolerances, and structural details.

Process Selection: Select a casting process (sand casting, metal mold casting, lost foam casting, etc.) based on the material (cast iron, cast steel, aluminum alloy, etc.) and production volume.

Simulation Analysis: Use CAE software to simulate the mold filling and solidification processes to optimize the gating system and riser design to minimize defects.

2. Mold/Pattern Production

Sand Casting: Create wooden or metal molds (for molding), or use 3D printing technology to directly create sand molds.

Metal Mold Casting: Fabricate steel or cast iron molds suitable for large-scale production.

Investment Casting: Create wax patterns and coat them with multiple layers of refractory material to form a precise mold shell.

3. Molding and Core Making

Molding: Fill the mold with molding sand (clay sand, resin sand, etc.) to form the outer cavity of the casting. Core Making: Sand cores are made (used to form the inner cavity or complex structure of the casting) and placed into the mold after drying or solidification.

4. Melting and Pouring

Melting: The metal is melted into a liquid state in a cupola, electric arc furnace, or induction furnace, and its composition (such as carbon and silicon content) is adjusted.

Furnace Inspection: The temperature and chemical composition of the molten metal are measured (spectroscopic analysis).

Pouring: The molten metal is poured into the mold cavity, controlling the pouring rate and temperature to avoid defects such as pores and cold shuts.

5. Cooling and Shakeout

Cooling: The casting cools naturally in the mold cavity until it solidifies. The time required depends on the material and wall thickness.

Shakeout: The sand is removed by vibration or manual means, and the casting is removed (avoid forceful hammering to avoid cracking).

6. Cleaning and Post-Processing

Gating and Riser Removal: The gating system and riser are separated by cutting, grinding, or hammering.

Surface Cleaning: Shot blasting, shot blasting, or pickling are used to remove scale and residual sand. Welding/Repair: Welding or filling surface defects (such as pinholes).

Raw Material Control

Pig Iron/Scrap: Select high-purity raw materials and control sulfur and phosphorus content (generally sulfur <0.1%, phosphorus <0.15%) to avoid impurities that cause brittleness.

Alloying Elements: Add silicon, manganese, and other elements as needed to adjust strength and hardness (for example, HT250 cast iron requires carbon 3.1-3.4% and silicon 1.8-2.2%).

Pre-Furnace Analysis: Spectroscopic analysis of the molten iron is performed before smelting to ensure that the composition meets the specified standards.

Gray Cast Iron (HT)

Features: Low cost, excellent castability, strong vibration damping, and wear resistance.

Applications: Machine tool bases, engine blocks, and general machinery bases.

Example grades: HT150, HT200 (the number represents tensile strength).

Ductile Iron (QT)

Features: High strength, good toughness (close to steel), and fatigue resistance.

Applications: Heavy equipment bases, gearboxes, and wind turbine components.

Examples: QT400-18, QT600-3.

Compacted Graphite Iron (RuT)

Features: A grade between gray iron and ductile iron, with good thermal fatigue resistance.

Applications: Bases or housings for high-temperature applications.

2. Cast Steel (High strength, high toughness, suitable for heavy loads or impact environments)

Carbon Steel Castings (ZG)

Features: Weldable, with mechanical properties superior to cast iron, but at a higher cost.

Surface milling: Ensures the flatness of the base mounting surface; Contour milling: Machining the base's contours; Slot milling: Machining mounting slots, locating slots, etc.; Mounting hole machining: For equipment fastening; Threaded hole machining: For connecting other components; Dowel pin hole machining: Ensures mounting accuracy; Machining large precision holes; Ensuring hole coaxiality and positional accuracy; Finishing precision surfaces; Improving surface finish and flatness.

Strictly inspect metal material composition to ensure compliance with standard requirements; Control furnace charge ratios to avoid excessive levels of impurities; Classify and pre-treat returned materials; Precisely control melting temperature and time; Conduct rapid pre-furnace composition analysis; Implement effective deoxidation and degassing processes; Control pouring temperature within a reasonable range; Optimize mold design to ensure a suitable pouring and feeding system; Control molding sand properties (permeability, strength, moisture content, etc.); Ensure a reasonable cooling rate and solidification sequence; Regularly inspect mold dimensions and wear; Control casting shrinkage; Use precision testing equipment such as coordinate measuring machines; Conduct non-destructive testing (X-ray and ultrasonic); Establish defect classification standards and treatment procedures; Conduct 100% inspection of key areas; Implement casting repair process verification; Develop a reasonable heat treatment process profile; Control furnace temperature uniformity and workpiece placement; Conduct hardness testing and metallographic examinations; Record heat treatment process parameters; Control casting surface roughness; Inspect for surface defects (pores, pinholes, cracks, etc.); Perform mold surface cleaning and sandblasting; Implement rust prevention treatment

1: Advanced technology and equipment standards

Advanced technology: Sand casting, precision casting, and lost foam casting process. Casting sizes according to customer requirements, weights ranging from 0.5kg to 10,000kg

Automation equipment: Equipped with automated production lines, intelligent melting furnaces (medium frequency/high frequency induction furnaces),

Inspection equipment: Chemical composition/spectrometer and mechanical property inspection equipment, three-coordinate measuring machine (CMM), X-ray flaw detector, spectrometer, ultrasonic testing and other high-end quality inspection methods.

2:Quality management system

ISO 9001 (quality management system)

IATF 16949 (automotive industry quality management system, such as automotive parts)

ASTM/EN/JIS and other international material standards.

3:Customization capability

Customized production according to customer drawings, customers only need to pay half of the mold fee to develop new castings. The mold time is short, only 20 days, and the casting time only 10 days. Machining 10 days.

Free express sample to customers, mass production after customer samples are confirmed to be fully qualified. Our company does not require customers to place a minimum order quantity, satisfying customers with a variety of choices

4:Competitive prices

Our company’s prices are very competitive in the industry, and the specific price depends on the casting drawing and the customer’s order quantity. Welcome to inquire

Carbon, silicon, manganese, sulfur, phosphorus, chromium, nickel, copper and other elements

Tensile strength, yield strength, elongation, hardness, impact strength

Three-coordinate inspection, non-destructive testing, pressure testing, etc.

Every parts we will use anti-rust oil packing or primer, keep every parts in good condition after long time shipping.For small parts, we use wood box pallet packing.For bigger parts with pallet packing

Jiangsu Shengrong High end Equipment Manufacturing Industry Co., Ltd is a professional iron casting foundry about 26,000 square meters, Investment of 80 million yuan,include intermediate frequency furnace, new east Seoul horizontal line, cast star horizontal line, micro crystal automatic casting machine, 40T mixer and 20T mixer, core-making machine, shot blasting machine, machining center, inclined rail lathe, slot machine, vertical lathe, flat rail lathe and other equipment.Testing equipment:spectrometer, tensile testing machine, hardness tester, etc., and supporting chemical testing laboratories. Mainly engaged in: mechanical parts, auto parts, industrial pump parts, bearings and transmission parts manufacturing. Company’s main business: QT450-12, 500-7, 600-3 ball mill castings and HT250, HT300 gray iron castings and cast steel, stainless steel and other business, with the increase of business volume, the production is not only to meet the main business, while the product after the process of product processing business development, so that enterprises diversified production. Now the company has more than 100 employees, including a professional management team and new product development.

CONTACT

Get In Touch