Jiangsu Shengrong Casting Co., Ltd. produces various types of counterweights made of gray iron HT250. The sizes can be customized and the weight range is from 50 kg to 2000 kg. The delivery time is short and the price is low.

Material: gray cast iron

Our cast iron parts are of high precision, wear resistance, low price and fast delivery, and are well received by customers

Material: Cast iron HT200/GG20

Standard/tollerance: EN1561-2011/GB/T 9439/GB/T 1348

Size and weight: According to drawing

High Density and Weight Stability: Cast iron (such as gray cast iron and ductile iron) has a high density (approximately 6.8-7.3 g/cm³), offering a high weight per unit volume, making it suitable for counterweight applications requiring a compact design.

The material's excellent stability prevents deformation or degradation over time, ensuring the long-lasting effectiveness of the counterweight.

Excellent Mechanical Properties: Cast iron offers excellent pressure resistance, making it suitable for supporting static loads (such as machinery bases and elevator counterweights).

Wear Resistance: Its high surface hardness resists minor friction and environmental wear.

Shock Absorption: Cast iron's internal graphite structure absorbs vibration and is often used to reduce mechanical vibration (such as in machine tool counterweights).

The casting process allows for complex shapes to accommodate various installation requirements (such as special-shaped holes and grooves).

The surface can be machined (drilled and milled), facilitating connection to other components.

Industrial: Stamping machines, injection molding machines, crane counterweights.

Transportation equipment: Vehicle counterweights, track ballasts.

Construction: Elevator counterweights, temporary structure stabilization weights.

Materials: Gray cast iron (HT150, HT200), ductile iron (QT400-18, QT500-7), etc.

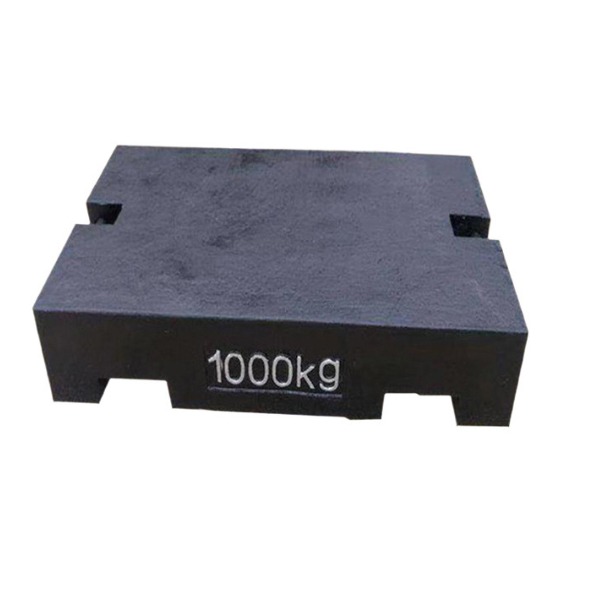

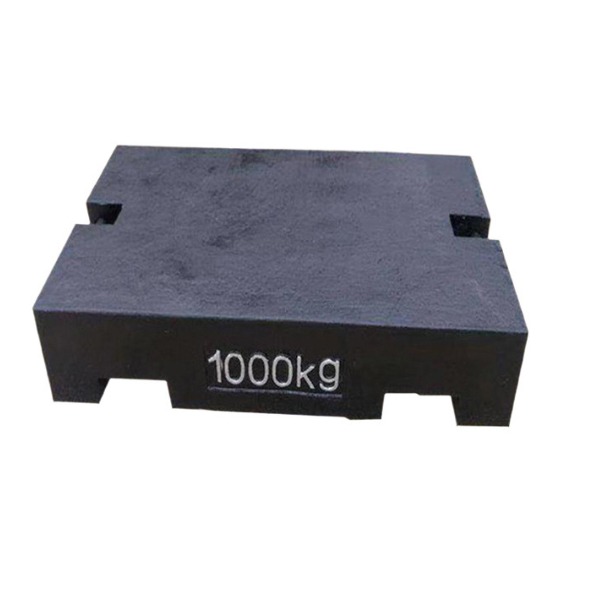

Weight Range: Single unit weights range from a few kilograms to several tons. Common specifications include:

Small: 5kg, 10kg, 20kg, 50kg

Medium: 100kg, 200kg, 500kg

Large: 1 ton, 2 tons, 5 tons (requires individual unit designs)

Dimensions: Designed based on weight and intended use. Common shapes include rectangular, cylindrical, or special shapes.

Example (rectangular):

Tolerance: Weight tolerance is typically ±2% to ±5%. Dimensional tolerances are in accordance with GB/T 6414 or customer specifications. International/National Standards:

GB/T 9439 (Gray Iron Castings)

GB/T 1348 (Ductile Iron Castings)

ISO 185 (Gray Iron Classification)

Surface Treatment: Anti-rust coating (e.g., asphalt paint, galvanizing), unfinished or rough-finished surfaces.

High Density and Weight Stability: Cast iron (such as gray cast iron and ductile iron) has a high density (approximately 6.8-7.3 g/cm³), offering a high weight per unit volume, making it suitable for counterweight applications requiring a compact design.

The material's excellent stability prevents deformation or degradation over time, ensuring the long-lasting effectiveness of the counterweight.

Excellent Mechanical Properties: Cast iron offers excellent pressure resistance, making it suitable for supporting static loads (such as machinery bases and elevator counterweights).

Wear Resistance: Its high surface hardness resists minor friction and environmental wear.

Shock Absorption: Cast iron's internal graphite structure absorbs vibration and is often used to reduce mechanical vibration (such as in machine tool counterweights).

The casting process allows for complex shapes to accommodate various installation requirements (such as special-shaped holes and grooves).

The surface can be machined (drilled and milled), facilitating connection to other components.

Industrial: Stamping machines, injection molding machines, crane counterweights.

Transportation equipment: Vehicle counterweights, track ballasts.

Construction: Elevator counterweights, temporary structure stabilization weights.

Materials: Gray cast iron (HT150, HT200), ductile iron (QT400-18, QT500-7), etc.

Weight Range: Single unit weights range from a few kilograms to several tons. Common specifications include:

Small: 5kg, 10kg, 20kg, 50kg

Medium: 100kg, 200kg, 500kg

Large: 1 ton, 2 tons, 5 tons (requires individual unit designs)

Dimensions: Designed based on weight and intended use. Common shapes include rectangular, cylindrical, or special shapes.

Example (rectangular):

Tolerance: Weight tolerance is typically ±2% to ±5%. Dimensional tolerances are in accordance with GB/T 6414 or customer specifications. International/National Standards:

GB/T 9439 (Gray Iron Castings)

GB/T 1348 (Ductile Iron Castings)

ISO 185 (Gray Iron Classification)

Surface Treatment: Anti-rust coating (e.g., asphalt paint, galvanizing), unfinished or rough-finished surfaces.

1. Design and Mold Preparation

Drawing Design: Determine the dimensions, weight, and mechanical property requirements based on the intended use of the counterweight (e.g., mechanical balancing, ship ballast, etc.).

Mold Fabrication: Sand casting (wooden/metal) or metal casting is used. The mold must take into account shrinkage (typically around 1% for cast iron).

2. Melting and Pouring

Raw Material Preparation: Pig iron, scrap steel, recycled materials, and alloying elements (such as carbon and silicon) are mixed in appropriate proportions.

Melting: Heat to 1400-1500°C in a cupola or electric furnace (intermediate frequency furnace), and adjust the composition (e.g., carbon equivalent, C).

Furnace Inspection: Rapidly analyze the molten iron composition (spectrometer) and temperature (thermocouple).

Pouring: Pour the molten iron into the mold, controlling the flow rate to avoid porosity and slag inclusions.

3. Cooling and Sand Dropping

Natural Cooling: The casting solidifies in the mold (time depends on the wall thickness, typically several hours). Sand removal: Vibrate or manually remove the sand mold and remove the casting (be careful to avoid deformation due to high temperatures).

4. Cleaning and Post-Processing

Removing the riser: Clean with gas cutting, a grinding wheel, or hammering.

Surface treatment: Sandblasting/shot blasting to remove oxide scale and residual sand.

Grinding: Trim burrs and flash.

5. Heat Treatment (Optional)

Annealing/Aging: Eliminate internal stresses (e.g., heating to 500-600°C and slow cooling).

Other Treatments: Ductile iron may require normalizing or quenching to increase hardness.

6. Machining (As Needed)

Turning/Milling/Drilling: Machine critical dimensions or mounting holes (e.g., counterweight connection surfaces).

7. Quality Inspection

Dimensional Inspection: Calipers, CMM.

Appearance Inspection: Check for defects such as cracks and pores (visual inspection or flaw detection).

Weight Verification: Weigh with an electronic scale to ensure within tolerances. Performance Testing: Hardness (Brinell hardness HB), Tensile Strength (sampling destructive test).

8. Surface Rust Prevention and Painting

Rust Prevention: Spraying with anti-rust oil or phosphating.

Painting: Apply primer and topcoat as required (e.g., salt spray resistant paint is required for ship counterweights).

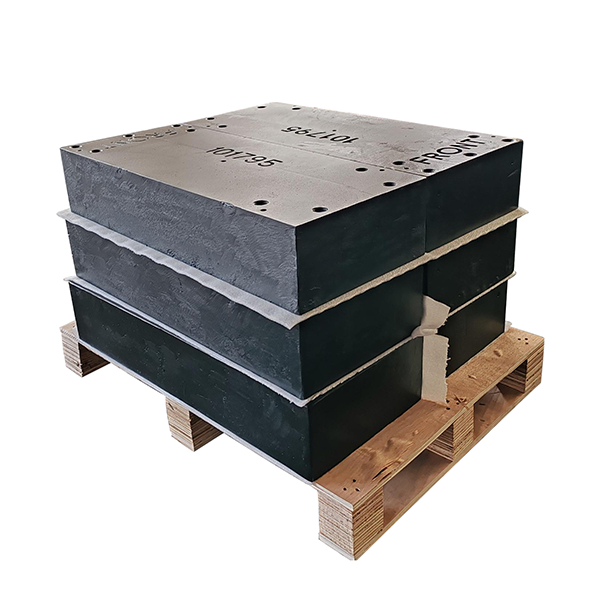

9. Packaging and Warehousing

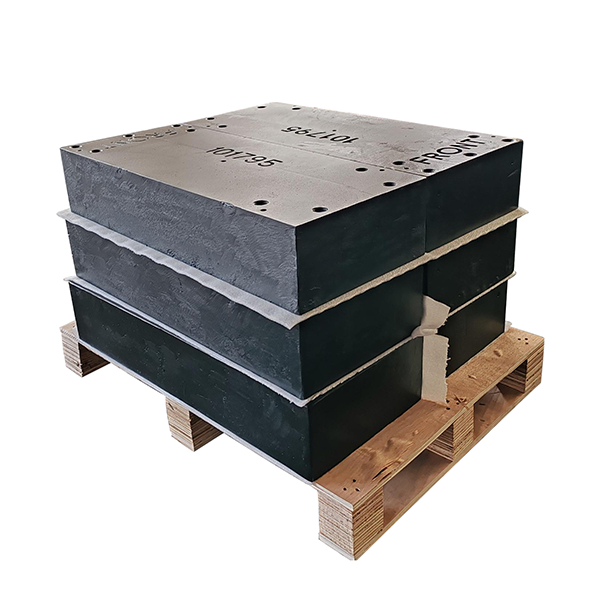

Packaging: Securely packed in wooden boxes or pallets to prevent collisions during transportation.

Marking: Marking with information such as weight and batch number.

Raw Material Control

Pig Iron/Scrap: Select high-purity raw materials and control sulfur and phosphorus content (generally sulfur <0.1%, phosphorus <0.15%) to avoid impurities that cause brittleness.

Alloying Elements: Add silicon, manganese, and other elements as needed to adjust strength and hardness (for example, HT250 cast iron requires carbon 3.1-3.4% and silicon 1.8-2.2%).

Pre-Furnace Analysis: Spectroscopic analysis of the molten iron is performed before smelting to ensure that the composition meets the specified standards.

Melting and Pouring Process

Temperature Control: The molten iron tapping temperature must be ≥1450°C, and the pouring temperature must be 1300-1400°C to avoid cold shuts and air holes.

Inoculant Treatment: Inoculants such as ferrosilicon are added to refine the graphite and improve mechanical properties (e.g., tensile strength ≥250 MPa).

Pouring Speed: A steady pouring process is employed to minimize slag inclusions, and an inclined pouring system is used to reduce turbulence.

Molding and Cooling

Mold Design: Ensure sand mold hardness (≥80 green compressive strength) and air permeability. Resin-reinforced sand can be used to improve precision for complex parts.

Cooling Rate: Control the unpacking time (generally over 24 hours) to avoid excessive cooling and internal stress cracks.

Machining and Dimension Control

Machining Reference: Critical mounting surfaces are machined using non-critical surfaces as the reference, with a flatness tolerance of ≤0.2mm/m.

Weight Compensation: Reserve a machining allowance (usually 3-5mm). After machining, weigh and level the parts (e.g., crane counterweights have a tolerance of ±2%).

Appearance Inspection: Visual inspection or magnetic particle inspection for surface cracks and shrinkage cavities (defect area <5%).

Dimensional Inspection: Critical dimensions are measured using three-dimensional coordinate measurement to ensure conformance to drawing tolerances (e.g., ±0.5mm).

Performance Testing:

Density: Spot-check actual density (gray cast iron, approximately 7.1-7.3 g/cm³).

Hardness: Brinell hardness HB180-250 (depending on grade).

Dynamic Balancing (rotating component counterweight): Residual unbalance ≤ G2.5 standard.

1: Advanced technology and equipment standards

Advanced technology: Sand casting, precision casting, and lost foam casting process. Casting sizes according to customer requirements, weights ranging from 0.5kg to 10,000kg

Automation equipment: Equipped with automated production lines, intelligent melting furnaces (medium frequency/high frequency induction furnaces),

Inspection equipment: Chemical composition/spectrometer and mechanical property inspection equipment, three-coordinate measuring machine (CMM), X-ray flaw detector, spectrometer, ultrasonic testing and other high-end quality inspection methods.

2:Quality management system

ISO 9001 (quality management system)

IATF 16949 (automotive industry quality management system, such as automotive parts)

ASTM/EN/JIS and other international material standards.

3:Customization capability

Customized production according to customer drawings, customers only need to pay half of the mold fee to develop new castings. The mold time is short, only 20 days, and the casting time only 10 days. Machining 10 days.

Free express sample to customers, mass production after customer samples are confirmed to be fully qualified. Our company does not require customers to place a minimum order quantity, satisfying customers with a variety of choices

4:Competitive prices

Our company’s prices are very competitive in the industry, and the specific price depends on the casting drawing and the customer’s order quantity. Welcome to inquire

Carbon, silicon, manganese, sulfur, phosphorus, chromium, nickel, copper and other elements

Tensile strength, yield strength, elongation, hardness, impact strength

Three-coordinate inspection, non-destructive testing, pressure testing, etc.

Every parts we will use anti-rust oil packing or primer, keep every parts in good condition after long time shipping.For small parts, we use wood box pallet packing.For bigger parts with pallet packing

Jiangsu Shengrong High end Equipment Manufacturing Industry Co., Ltd is a professional iron casting foundry about 26,000 square meters, Investment of 80 million yuan,include intermediate frequency furnace, new east Seoul horizontal line, cast star horizontal line, micro crystal automatic casting machine, 40T mixer and 20T mixer, core-making machine, shot blasting machine, machining center, inclined rail lathe, slot machine, vertical lathe, flat rail lathe and other equipment.Testing equipment:spectrometer, tensile testing machine, hardness tester, etc., and supporting chemical testing laboratories. Mainly engaged in: mechanical parts, auto parts, industrial pump parts, bearings and transmission parts manufacturing. Company’s main business: QT450-12, 500-7, 600-3 ball mill castings and HT250, HT300 gray iron castings and cast steel, stainless steel and other business, with the increase of business volume, the production is not only to meet the main business, while the product after the process of product processing business development, so that enterprises diversified production. Now the company has more than 100 employees, including a professional management team and new product development.

CONTACT

Get In Touch