Metal casting involves a variety of technologies and processes. Casting design is the most critical consideration for each foundry. The overall casting design method ensures the optimization of the casting process, minimizes defects, and has a vital impact on the quality of casting products. A reasonable and scientific casting design can ensure the quality, production efficiency and economic benefits of castings. The following is a detailed analysis of how the casting design affects the quality of casting products:

1. The impact of casting process parameters

1.1 Pouring temperature:

The appropriate pouring temperature can ensure that the molten metal has good fluidity and filling properties in the mold, thereby avoiding defects such as cold shut and insufficient pouring.

Too high a pouring temperature may cause defects such as shrinkage cavities and shrinkage in the casting, while too low a pouring temperature may cause defects such as cold shut and insufficient pouring on the surface of the casting.

1.2 Pouring speed:

Pouring speed that is too fast can easily cause pores and inclusions, affecting the internal quality of the casting.

Too slow a pouring speed may cause uneven solidification of the casting and defects such as thermal cracks.

1.3 Shrinkage rate:

Accurate shrinkage rate calculation can ensure that the size of the casting after cooling is consistent with the requirements of the drawing, avoiding quality problems caused by dimensional deviation.

2. Selection of casting method

2.1 Sand casting:

It is suitable for castings of various types and sizes, but there may be certain defects in the surface roughness and internal structure of the casting. It is necessary to select the appropriate sand mold material, molding method and pouring system according to the requirements of the casting.

2.2 Lost foam casting:

It has the advantages of high precision, flexible design, no parting surface and draft angle, and is suitable for mass production of small and medium-sized castings.

2.3 Metal mold casting:

It has the advantages of high efficiency, high precision and high repeatability, and is suitable for mass production of small and medium-sized castings.

It requires precise mold design and strict process control.

2.4 Pressure casting:

It is suitable for the production of complex, thin-walled, high-strength castings, with the advantages of high efficiency and high precision.

It is necessary to select a suitable pressure casting machine, mold design and pouring system, and strictly control the process parameters.

2.5 Investment casting:

It is suitable for making high-quality, complex-shaped castings, but the process is complicated and the cost is high.

It requires precise molding, dewaxing, roasting and pouring steps, as well as a strict post-processing process.

3. Design of mold and gating system

3.1 Mold design:

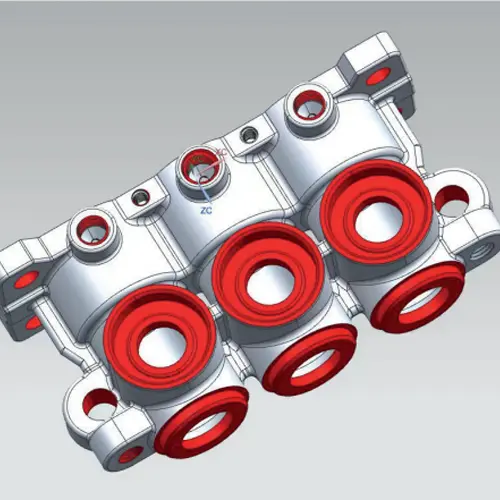

The structure, size and precision of the mold directly affect the shape, size and surface quality of the casting. It is necessary to carry out precise mold design and manufacturing according to the requirements of the casting. Shrinkage and deformation are two key considerations. Surface finish and dimensional accuracy are key indicators for fine mold design. Optimizing these factors enables us to achieve precise dimensional accuracy.

3.2 Gating system design:

The structure, position and size of the gating system affect the flow and filling effect of the molten metal, which in turn affects the quality of the casting. It is necessary to design a reasonable gating system according to the structure, material and production requirements of the casting to minimize turbulence and air entrapment. The appropriate riser setting can effectively solve common defects such as shrinkage.

4. Quality control in the casting process

4.1 Raw material quality control:

The quality of the raw materials directly affects the quality of the casting. The influence of material properties on product performance and quality is multifaceted. It is necessary to select casting materials that meet the requirements and strictly control the chemical composition of raw materials.

4.2 Process control:

Every link in the casting process needs to be strictly controlled, including smelting, molding, pouring, sanding, cleaning and inspection. Detailed process operation procedures and quality inspection standards need to be formulated to ensure the stability and controllability of the process.

5. Post-casting process with effective design

The post-casting process mainly includes machining, surface treatment and heat treatment.

5.1 Machining involves the use of various cutting tools and techniques. This process is used to achieve precise dimensions and smooth surfaces. It is suitable for specific geometric shapes that are difficult to achieve only by casting methods. Common machining operations include turning, milling, drilling and grinding.

5.2 Surface treatment aims to improve the surface quality and appearance of castings. These processes include polishing, grinding and coating to eliminate surface defects and can provide additional corrosion or wear protection.

5.3 Heat treatment is a controlled heating and cooling process applied to castings. Different types of heat treatment include annealing, normalizing, quenching and tempering. To change its mechanical properties and improve the hardness, strength and toughness of castings.

Casting design is not just a process. Its multifaceted impact will run through every stage of metal manufacturing. Casting design becomes the key to determine the quality of casting products.

Shengrong iron casting foundry casting process as below: