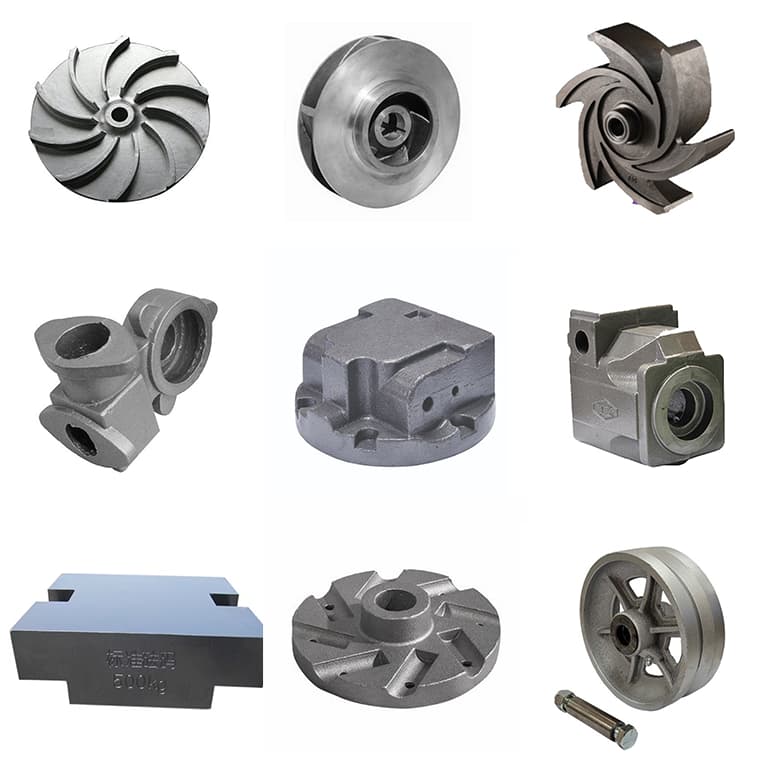

A pump casting creates the essential structural components of pumps through precision metal casting processes, delivering durable housings, impellers, and volutes that ensure reliable fluid handling. You find these cast components critical in water systems, industrial processes, and infrastructure applications where performance and longevity matter most.

Manufacturing defects can cause up to 45% of pump failures, but quality pump casting can reduce maintenance costs by up to 60% while extending equipment life by decades.

You benefit from professional pump casting through enhanced durability, precise dimensional accuracy, and cost-effective production. The growing demand for advanced pump casting solutions reflects their vital role in modern industrial applications.

Key Takeaways

- Pump casting produces critical pump components, including housings, impellers, and volutes, through precision metal casting processes.

- Quality casting materials like ductile iron and stainless steel ensure corrosion resistance and mechanical strength for demanding applications.

- Advanced casting techniques improve dimensional accuracy, reduce porosity, and deliver superior surface finishes for optimal pump performance.

- Proper casting design considerations, including wall thickness and cooling rates, prevent defects and ensure reliable long-term operation.

- Regular quality control and testing protocols maintain casting standards and protect your equipment investment over time.

Pump Casting Overview

What Is a Pump Casting?

You may encounter terms like pump housing casting, impeller casting, or volute casting used to describe specific components. A pump casting is a precision-manufactured metal component created through controlled casting processes for pump assemblies in industrial, municipal, and commercial applications. This process transforms molten metal into complex pump geometries that would be difficult or impossible to machine from solid stock.

Note: Pump casting enables the production of intricate internal passages, complex curves, and integrated features that optimize fluid flow and pump efficiency.

You will find several types of pump casting materials, each designed for specific operating conditions. The table below shows common casting materials and their applications:

| Casting Material | Corrosion Resistance | Strength Level | Performance Applications | Industry Standards |

| Ductile Iron | Good | High | Water systems, general industrial | ASTM A536, ISO 1083 |

| Gray Cast Iron | Fair | Moderate | Low-pressure, non-corrosive fluids | ASTM A48, ASTM A126 |

| Carbon Steel | Good | High | High-pressure applications, industrial | ASTM A216, ASTM A27 |

These material standards help you select the right pump casting for your specific application. Pump casting components must also meet industry standards such as API specifications, ANSI, and ISO requirements to ensure safety and performance.

How It Works

A pump casting uses a systematic manufacturing process. You begin with pattern creation, followed by mold preparation, metal pouring, and finishing operations. The casting process creates hollow sections, complex internal geometries, and precise external features in a single operation.

The key steps include:

- Pattern making creates the positive form of the desired pump component.

- Mold preparation establishes the cavity space for molten metal.

- Metal pouring fills the mold under controlled temperature and timing conditions.

You benefit from pump casting in several ways:

Casting allows complex internal passages that optimize fluid flow and minimize turbulence. This precision manufacturing reduces energy consumption and improves pump efficiency.

You can produce components with integrated features, eliminating assembly joints and reducing potential leak points.

The casting process enables cost-effective production of both prototype and high-volume quantities.

Tip: Many leading pump manufacturers rely on specialized pump casting foundries to achieve the precision and quality required for critical applications.

Recent industry developments highlight the importance of advanced pump casting:

- Global pump market growth drives demand for higher-quality casting components

- Advanced metallurgy techniques improve casting strength and corrosion resistance

- Investment casting processes achieve tolerances within ±0.005 inches for critical dimensions

- Computer modeling optimizes casting designs before production, reducing defects by up to 40%

Pump casting supports sustainability goals through material efficiency and recyclability of metal components.

When you plan pump casting production, you should:

- Design appropriate wall thickness to prevent defects while maintaining strength

- Select proper gating and riser systems for complete mold filling

- Choose cooling rates that optimize grain structure and mechanical properties

- Implement quality control measures, including dimensional inspection and material testing

- Plan heat treatment processes to achieve required hardness and strength specifications

Pump casting provides the precision, durability, and cost-effectiveness needed in modern fluid handling systems. You can achieve complex geometries, superior material properties, and reliable performance—all through proven casting technologies.

Components of Pump Casting

Housing and Volute Castings

You build pump assemblies using housing and volute castings as primary structural elements. Housing castings form the outer shell and provide mounting surfaces, while volute castings create the spiral chambers that convert kinetic energy to pressure. Each casting type serves specific hydraulic functions. Housing castings resist internal pressure and provide structural integrity, making material selection critical for safety. Volute castings shape fluid flow patterns and must maintain precise internal geometries for optimal efficiency. The casting process allows integration of mounting features, inspection ports, and connection flanges in single components, reducing assembly complexity and potential leak points.

| Component Type | Key Properties and Benefits | Application Areas | Critical Design Features |

| Housing Castings | Pressure resistance, structural strength, corrosion protection | Municipal water, industrial processing | Integrated mounting bosses, pressure boundaries, access ports |

| Volute Castings | Hydraulic efficiency, flow optimization, dimensional stability | Centrifugal pumps, process applications | Spiral geometry, smooth internal surfaces, discharge connections |

| Split Case Castings | Assembly flexibility, maintenance access, alignment precision | Large pumps, high-flow applications | Machined joint surfaces, dowel pin locations, bolt patterns |

Impeller and Internal Components

Impeller castings create the rotating elements that impart energy to pumped fluids. These components require precise blade geometry, balanced mass distribution, and smooth surface finishes for optimal performance. You can choose from various impeller designs, including closed, semi-open, and open configurations, based on application requirements. The casting process enables complex three-dimensional blade shapes that would be expensive to machine. Internal components like wear rings, diffusers, and guide vanes also benefit from casting manufacturing, allowing intricate flow passages and precise clearances.

Tip: Investment casting processes achieve the tight tolerances required for impeller components, typically maintaining ±0.003 inches on critical dimensions.

Surface Treatments and Finishes

Surface treatments protect pump castings and enhance performance characteristics. You can select from various coating systems, including epoxy, polyurethane, and ceramic options, depending on fluid compatibility and operating conditions. Mechanical finishes like shot blasting prepare surfaces for coating adhesion while removing casting scale. Some advanced treatments use plasma spray processes to apply wear-resistant coatings on high-erosion areas. Studies indicate that proper surface preparation can extend coating life beyond 15 years in municipal water applications. Corrosion resistance improves significantly with appropriate surface treatments, reducing maintenance requirements and extending pump service life.

You gain multiple advantages from quality pump casting components. You improve reliability, reduce maintenance costs, and achieve optimal hydraulic performance through precision-cast components designed for your specific application requirements.

Benefits in Industrial Applications

Durability and Strength

You achieve superior durability when you use quality pump casting in your industrial systems. The casting process creates components with excellent mechanical properties and resistance to operational stresses. Properly cast pump housings and impellers withstand high pressures, temperature variations, and continuous operation without failure. The controlled solidification process in casting produces fine-grain structures that enhance strength and fatigue resistance. Case studies show that well-designed pump castings can operate for decades with minimal wear, significantly reducing replacement costs and downtime.

Metallurgical testing confirms that cast components often exceed the strength of equivalent machined parts due to optimized grain flow and reduced stress concentrations. Heat treatment processes further enhance mechanical properties, allowing castings to meet demanding service requirements in chemical processing, power generation, and water treatment applications.

- Pump casting delivers enhanced mechanical strength compared to fabricated alternatives

- Controlled casting processes optimize grain structure for maximum durability

- Heat treatment capabilities allow customization of mechanical properties for specific applications

Cost-Effectiveness

A pump casting approach provides significant cost advantages over alternative manufacturing methods. You save money through reduced material waste, as casting uses only the metal needed for the final component shape. Complex geometries that would require multiple machined parts can be cast as single integrated components, eliminating assembly labor and reducing inventory requirements. The ability to produce both prototype and production quantities efficiently helps manage development costs and market entry timing.

Economies of scale in casting production reduce per-unit costs for larger quantities while maintaining quality standards. You also benefit from shorter lead times compared to extensive machining operations, helping you meet project deadlines and reduce carrying costs.

Tip: Consider total lifecycle costs when evaluating pump casting options, including reduced maintenance, longer service life, and improved energy efficiency.

Precision and Quality Control

You get exceptional precision through modern pump casting techniques and quality control systems. Advanced foundries use computer-controlled processes to maintain consistent temperatures, timing, and material composition throughout production. Dimensional inspection using coordinate measuring machines ensures castings meet specified tolerances, typically achieving ±0.010 inches on most features.

Non-destructive testing methods, including radiographic and ultrasonic inspection, detect internal defects before components enter service. Material testing confirms chemical composition and mechanical properties meet specification requirements. Statistical process control systems track quality metrics and identify improvement opportunities.

Digital modeling and simulation optimize casting designs before production begins, predicting potential defects and allowing design modifications to prevent problems. This approach reduces scrap rates and ensures first-article success on critical components.

A pump casting system provides the strength, cost-effectiveness, and precision needed in demanding industrial applications. You create more reliable, efficient pumping systems through quality casting components designed for your specific operational requirements.

Pump Casting Selection & Manufacturing Process

Choosing the Right Casting Process

You need to match your pump casting requirements to the appropriate manufacturing process. Start by evaluating your application environment, required quantities, dimensional tolerances, and budget constraints. Consider these key factors:

Process Selection: Sand casting suits large housings and prototype development. Investment casting achieves tight tolerances for impellers and complex geometries. Die casting works for high-volume production of smaller components.

Material Options: Ductile iron provides excellent strength and durability for water and industrial applications. Gray cast iron offers cost-effective solutions for standard pressure systems. Carbon steel delivers superior strength for high-pressure and demanding industrial environments.

Quality Requirements: Determine inspection needs, pressure testing requirements, and surface finish specifications. Plan for non-destructive testing if components are critical for safety.

Production Volume: Low quantities favor sand casting or investment casting. High volumes justify die casting tooling costs. Medium volumes often use permanent mold processes.

Dimensional Accuracy: Investment casting achieves ±0.005 inches. Sand casting typically provides ±0.030 inches. Consider post-casting machining for critical surfaces.

Budget Considerations: Balance tooling costs, per-piece pricing, and quality requirements. Factor in total lifecycle costs, including maintenance and replacement intervals.

Industrial case studies demonstrate that proper process selection reduces costs by 20-30% while improving component reliability. Always consult experienced casting engineers for complex applications requiring specialized expertise.

Manufacturing and Quality Control

Effective manufacturing requires systematic process control and quality assurance. Follow these essential steps for successful pump casting production:

Pattern and Tooling Preparation: Create accurate patterns with appropriate shrinkage allowances. Verify tooling dimensions before production begins. Plan gating and riser systems for complete fill and proper solidification.

Mold Preparation: Control sand composition, moisture content, and compaction for consistent mold properties. Maintain proper mold temperatures and cure times for bonded sand systems.

Melting and Pouring: Monitor metal chemistry through spectroscopic analysis. Control pouring temperature within ±25°F of specification. Use consistent pouring rates to prevent turbulence and inclusion defects.

Heat Treatment: Apply appropriate thermal cycles to achieve specified mechanical properties. Monitor furnace temperatures and cooling rates throughout the process.

Quality Inspection: Implement dimensional checking using calibrated measuring equipment. Perform non-destructive testing on critical components. Conduct pressure testing when required by specifications.

Professional foundries maintain ISO 9001 certification and follow industry-specific quality standards. They provide material test reports, dimensional inspection data, and traceability documentation with each shipment.

Installation and Maintenance Guidelines

Proper handling preserves casting quality during installation and service. You should:

Handling Procedures: Use appropriate lifting equipment rated for component weight. Protect machined surfaces during transportation and storage. Inspect castings for shipping damage before installation.

Installation Practices: Follow manufacturer torque specifications for bolted connections. Verify proper alignment using precision measuring tools. Apply specified sealants or gaskets to prevent leakage.

Maintenance Protocols: Schedule regular inspections based on operating conditions. Monitor for signs of corrosion, erosion, or mechanical damage. Replace wear components before they affect pump performance.

Performance Monitoring: Track operating parameters including pressure, flow, and vibration levels. Document maintenance activities and component condition assessments.

Inventory Management: Maintain spare castings for critical applications. Store components in clean, dry environments to prevent corrosion.

Tip: Establish relationships with qualified pump casting foundries before you need emergency replacements to ensure rapid response and consistent quality.

You achieve optimal results by selecting appropriate casting processes, implementing rigorous quality control, and following proven installation and maintenance practices. Quality pump casting foundries like SHENGRONG provide the expertise and capabilities needed for demanding industrial applications, ensuring your pumping systems deliver reliable, long-term performance.

FAQ

What materials are commonly used in pump casting?

You find ductile iron, gray cast iron, and carbon steel most frequently used for pump casting applications. Ductile iron provides excellent strength for water systems, gray cast iron offers cost-effective solutions for standard applications, and carbon steel delivers superior performance in high-pressure industrial environments.

How do you ensure quality in pump casting production?

You implement quality control through material testing, dimensional inspection, and non-destructive testing methods. Certified foundries maintain process controls and provide documentation to verify compliance with specifications.

Can pump castings be repaired if damaged?

Yes, many pump castings can be repaired through welding, machining, or specialized restoration techniques. However, critical pressure-containing components may require replacement depending on damage extent and safety considerations.

What tolerances can be achieved with pump casting?

You can achieve tolerances ranging from ±0.005 inches with investment casting to ±0.030 inches with sand casting processes. Critical dimensions often require post-casting machining for final accuracy.

How long do quality pump castings typically last?

Quality pump castings can provide 20-30 years of reliable service in appropriate applications. Service life depends on operating conditions, maintenance practices, and material selection for the specific environment.