A container corner casting forms the reinforced fitting located at each corner of a shipping container. This essential component allows cranes and handling equipment to lift, stack, and secure the shipping container safely.

Industry reports highlight several key benefits:

- Standardized corner casting design lets cranes lift containers from any orientation.

- Containers can be stacked and locked securely on ships, trucks, and trains.

- Standardization ensures compatibility with equipment worldwide, improving safety.

- Secure locking reduces handling time and lowers the risk of accidents.

- Reliable corner castings support efficient and safe global shipping.

A shipping container relies on each corner casting to maintain stability and protect cargo throughout transport.

Key Takeaways

- Container corner castings are strong metal fittings at each container corner that enable safe lifting, stacking, and securing.

- They follow strict ISO 1161 standards to ensure global compatibility and safety during transport.

- Corner castings connect with twist locks and stacking cones to keep containers stable and prevent shifting.

- Regular inspection and maintenance of corner castings prevent accidents and extend container lifespan.

- Damaged or worn corner castings must be replaced promptly to maintain container safety and strength.

- High-quality materials like corten steel and ductile iron provide corrosion resistance and durability.

- Certified corner castings from trusted foundries guarantee reliable performance in harsh shipping conditions.

- Proper use of corner castings and securing devices supports efficient, safe, and smooth global container handling.

What Is a Container Corner Casting?

Basic Structure

A container corner casting is a robust metal block designed to fit precisely at each corner of a shipping container. Manufacturers typically use corten steel or other strong metals to produce these castings, giving them excellent strength and corrosion resistance. Each casting weighs about 2.5 kg and features three standardized holes on its outward-facing surfaces. These holes allow cranes, forklifts, and other equipment to lift and secure the container safely. The top and bottom castings differ in their hole shapes and positions. Top castings have a stadium-shaped hole on the long side and a shield-shaped hole on the front or rear. Bottom castings include two stadium-shaped holes on opposite sides and a large stacking hole underneath. This design ensures that shipping container corner castings can connect with handling equipment worldwide.

Note: ISO 1161 sets strict requirements for the dimensions and thickness of each corner casting. For example, the minimum thickness is 18 mm, and the top plate must be at least 23 mm thick. These standards guarantee durability and safety during transport.

| Component/Characteristic | Description |

|---|---|

| Materials Used | Steel, ductile iron, aluminum, gray iron |

| Hole Shapes | Top: stadium (long side), shield (front/back); Bottom: two stadium (sides), stacking hole (underneath) |

| Thickness Requirements | Minimum 18 mm (casting), 23 mm (top plate) |

| Dimensional Limits | Max width: 66 mm; Max length: 127 mm (top aperture) |

| Positioning | Eight per container: TL, TR, BL, BR |

| Standard | ISO 1161 |

| Function | Lifting, stacking, securing containers |

| Durability | Corrosion-resistant metals |

Placement on Shipping Containers

Shipping container corner castings are always found at the eight corners of a standard ISO shipping container. These include the top left, top right, bottom left, and bottom right positions, with two of each type per container. This arrangement allows for secure stacking, lifting, and transport. The castings are mounted at the very edges of the container’s frame, forming the main connection points for handling equipment.

| Position | Quantity per Container | Description |

|---|---|---|

| Top Left | 2 | Mounted on the top left corner (viewed from door end) |

| Top Right | 2 | Mounted on the top right corner (viewed from door end) |

| Bottom Left | 2 | Mounted on the bottom left corner (viewed from door end) |

| Bottom Right | 2 | Mounted on the bottom right corner (viewed from door end) |

Longer containers, such as 45ft, 48ft, and 53ft models, may include intermediate corner castings. These extra fittings are positioned 40ft apart and have slightly different shapes and hole placements. This adjustment ensures that even larger containers remain compatible with standard handling and stacking systems.

Key Functions

Corner castings play several critical roles in the operation and safety of a shipping container. They serve as the main structural points for lifting, stacking, and securing containers during transport. When workers stack containers, they align each container corner casting directly on top of another, which maintains stability and prevents shifting. The castings bear most of the weight in stacked containers, providing essential support.

- Containers are stacked corner casting to corner casting for maximum stability.

- Accurate alignment prevents misalignment and uneven weight distribution.

- Twist locks and lashing rods connect through the holes in the castings, locking containers together and preventing movement during transit.

Shipping container corner castings also ensure global compatibility. Their standardized design allows any container to connect with cranes, trucks, ships, and trains worldwide. This interoperability is a key reason why shipping containers have become the backbone of international trade.

Tip: Always check that the spreader or lifting device connects securely to the corner castings before lifting a shipping container. Proper alignment and secure locking help prevent accidents and protect cargo.

Understanding how do corner castings function helps operators maintain safety and efficiency in every stage of container handling. By serving as the main points for lifting, stacking, and securing, container corner casting designs answer the question of how do corner castings function in real-world shipping environments. Their placement and structure show exactly how do corner castings function to keep cargo safe and operations smooth.

Importance

Structural Role

Corner castings form the backbone of every shipping container. These strong metal blocks sit at each corner and connect the container’s frame. They create an interlocking system that holds containers together when stacked. This system gives the container its strength and stability. Without proper corner castings, a shipping container cannot support heavy loads or withstand the stress of transport. The materials used—such as steel or ductile iron—are chosen for their ability to resist corrosion and damage. ISO standards set strict rules for the size and thickness of each casting. If a container does not meet these standards, it cannot be used for shipping. Regular inspections help ensure that each cargo container keeps its structural integrity. Damaged or worn castings can weaken the whole container, making it unsafe for use.

Note: The interlocking design of corner castings allows containers to bear heavy loads during stacking and storage. This design also supports the use of twist locks and bridge clamps, which keep containers secure.

Safety in Shipping Container Use

Shipping container corner castings play a key role in keeping workers and cargo safe. When containers are lifted, stacked, or moved, the castings provide secure points for cranes and other equipment. This reduces the risk of accidents during handling. If a corner casting fails, the container could shift or fall, putting people and goods in danger. For this reason, shipping companies check the condition of corner castings before every trip. They look for signs of corrosion, cracks, or deformation. Only containers with strong, undamaged castings are allowed to carry goods. This careful attention helps prevent accidents and protects valuable cargo.

- Regular checks for damage or rust

- Use of only ISO-compliant castings

- Immediate replacement of faulty parts

Intermodal Compatibility

Corner castings make it possible for shipping containers to move smoothly between ships, trains, and trucks. Their standardized design means that any container can fit on any mode of transport. Cranes lift containers by their corner castings and stack them securely on ships. Trains carry containers over long distances, using the same corner points for safe transport. Trucks pick up containers at ports or rail yards and deliver them to their final destination. This system saves time and money because goods do not need to be unpacked and repacked at each step. The use of standardized shipping container corner castings ensures that containers remain stable and secure, no matter how far they travel.

Tip: Standardized corner castings allow for seamless transfer of containers between different transport modes, making global trade faster and safer.

How They Work

Stacking and Lifting

Shipping containers rely on corner castings for safe stacking and lifting. These metal blocks sit at each corner and provide a secure interface for handling equipment. Stacking cones fit into the holes of the corner castings, connecting the corners of containers above and below. The conical shape of these devices prevents horizontal movement and keeps containers aligned. Workers use cranes or forklifts to lift containers by attaching to the corner castings. The design allows for quick and safe lifting from any direction.

- Stacking cones and corner castings work together to support heavy loads.

- High-strength steel or cast iron materials help resist corrosion and mechanical stress.

- Some stacking cones include self-locking features to keep containers in place during lifting.

Corner castings must withstand high compressive and shear forces. This strength allows workers to stack six to eight containers safely. The standardized design ensures that equipment at ports and terminals can handle containers from different manufacturers.

Tip: Always check that stacking cones and corner castings are free from damage before lifting or stacking containers.

Securing Mechanisms

Securing mechanisms play a vital role in keeping containers stable during transport. The lower corner castings have lock-actuating openings designed to engage with securement devices on trucks, trains, or ships. These devices feature rotatable heads that fit into the openings of the corner castings. When a container is lowered onto the support, the mechanism automatically locks it in place.

Corner castings serve as the main load-bearing points. They distribute the weight of the container evenly and maintain structural integrity. The standardized apertures allow for the secure attachment of twist locks, which interlock containers and prevent movement. This system keeps containers from shifting due to vibrations or rough seas. In every mode of transport, twist locks engage with corner castings to keep containers firmly attached to vehicles or other containers.

Twist Locks and Fittings

Twist locks and corner castings form a standardized connector system. The corner casting acts as the female part with an oval hole, while the twist lock serves as the male part. Workers insert the twist lock into the hole and rotate it 90 degrees to secure the connection. This simple action locks containers together or attaches them to transport vehicles.

There are several types of twist locks:

- Manual twist locks: Workers operate these by hand, often used for stacking.

- Semi-automatic twist locks: These lock automatically under load but require manual unlocking.

- Fully automatic twist locks: These lock and unlock without human help, ideal for busy ports.

- Dovetail twist locks: Designed for flat surfaces, attached by welding or bolting.

- Horizontal twist locks: Used to connect containers side by side.

Twist locks must meet strict standards for size and strength. Each connection can support up to 25 tons. Some twist locks include levers or springs to ensure a firm lock. The materials and dimensions always match ISO 1161 requirements, which guarantees worldwide compatibility with corner castings. This system allows for safe lifting, stacking, and transfer between ships, trains, and trucks.

Note: The interaction between twist locks and corner castings prevents containers from sliding, shifting, or falling during transit, making global shipping safer and more efficient.

Types and Materials

Steel Grades

Manufacturers choose steel for corner castings because it can handle heavy loads, resist wear, and absorb shock. Steel also stands up well to corrosion, which is important for containers that travel across oceans and face harsh weather. This material keeps its strength even in freezing temperatures as low as -40°C. These qualities make steel the top choice for corner castings used in shipping containers.

To meet strict safety and quality standards, cast steel corner castings must follow IMO rules and ISO 1161 requirements. Production takes place in approved foundries that check every batch for soundness, mechanical strength, weldability, and precise dimensions. The steel’s chemical makeup must match national standards, with a carbon equivalent below 0.45%. Heat treatment, such as normalization or quenching and tempering at temperatures above 550°C, improves the steel’s durability. Each batch goes through mechanical tests, including tensile strength checks, to ensure the corner castings can handle the demands of global shipping.

Manufacturing Methods

The process of making corner castings involves several careful steps. Foundries start by designing and producing molds that shape the metal accurately. Workers then control the metal’s composition and remove impurities to keep the molten steel pure. During casting, they manage the pouring speed, temperature, and fluidity to form solid corner castings without defects.

After pouring, the metal cools and hardens. The cooling time and method are adjusted to prevent cracks or other problems. Once the corner castings are removed from the molds, they go through cleaning, polishing, and surface treatments. These steps improve both appearance and resistance to corrosion and wear. Quality control teams analyze the metal’s composition and test its mechanical properties. This ensures every corner casting meets strict standards for strength and durability.

Tip: Careful manufacturing and strict quality checks help corner castings last longer and perform better in tough shipping environments.

Top vs Bottom Castings

Corner castings come in two main types: top and bottom. Both types share the same high level of strength and quality, but their shapes and hole placements differ to fit their roles on the container.

- Bottom corner castings have two stadium-shaped holes on the side and front, plus a large stacking hole underneath.

- Top corner castings feature a stadium-shaped hole on the long side and a shield-shaped hole on the front or rear.

- The stacking hole sits underneath for bottom castings and on top for top castings.

- Left and right versions are mirror images, but otherwise, the design stays the same.

These differences help corner castings connect with lifting and securing equipment. The unique hole shapes and positions allow cranes, twist locks, and stacking cones to fit securely, keeping containers stable during transport.

Note: Both top and bottom corner castings must meet the same strict standards for strength and durability, ensuring safe handling and stacking in any shipping situation.

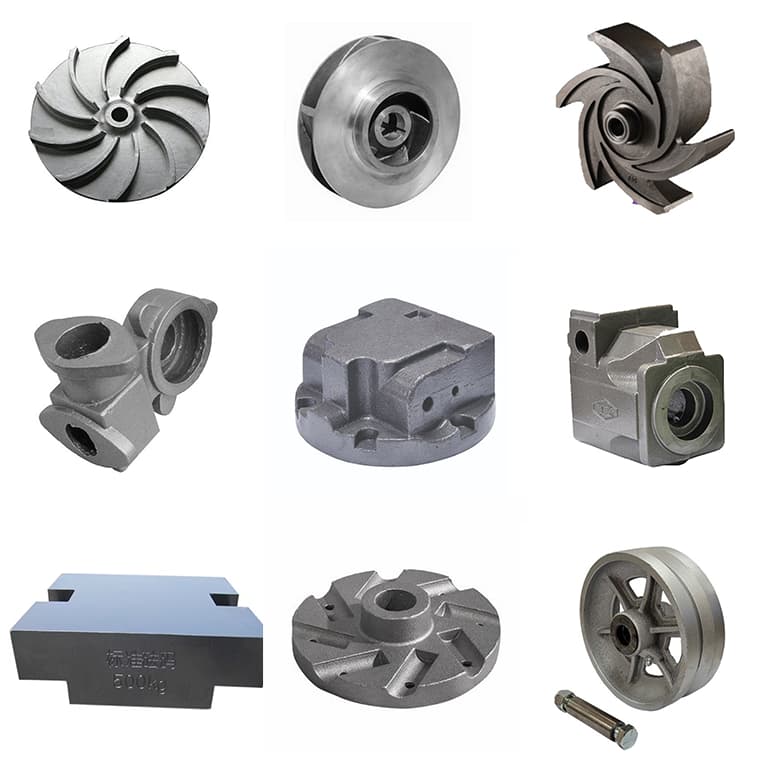

Shengrong Iron Casting

Shengrong operates as a specialized foundry that produces high-quality corner castings for shipping containers. The company focuses on iron casting techniques that deliver strong and reliable products. Their expertise ensures that each corner casting meets strict industry standards for strength, durability, and compatibility.

Shengrong uses advanced casting methods to shape iron into precise forms. Workers monitor every step of the process, from melting the raw material to pouring it into molds. They control temperature and timing to prevent defects. After cooling, each corner casting undergoes cleaning and inspection. Quality control teams check for cracks, uneven surfaces, and other flaws. Only castings that pass these tests move forward for shipment.

Note: Reliable corner castings protect cargo and support safe container handling. Shengrong’s process reduces the risk of weak points or failures.

Material quality plays a key role in the performance of corner castings. Shengrong selects iron with the right chemical composition to resist corrosion and mechanical stress. The foundry uses heat treatment to improve toughness and extend the lifespan of each casting. Workers test samples for tensile strength and hardness. These steps guarantee that corner castings can handle heavy loads and harsh environments.

Shengrong follows international standards for container corner castings. The foundry checks dimensions and hole placements to match ISO 1161 requirements. This attention to detail ensures that every corner casting fits securely with cranes, twist locks, and stacking cones. Customers receive products that work with equipment worldwide.

The manufacturing process at Shengrong includes several stages:

- Raw material selection: Workers choose iron with the right properties.

- Melting and casting: The foundry melts iron and pours it into molds shaped for corner castings.

- Cooling and cleaning: Castings cool slowly to avoid cracks, then workers clean and polish them.

- Inspection and testing: Quality teams check each corner casting for defects and measure strength.

- Certification: Shengrong certifies that castings meet ISO standards before shipping.

| Step | Purpose | Result |

|---|---|---|

| Material Selection | Ensures proper composition | Strong, corrosion-resistant |

| Casting | Shapes iron into corner castings | Accurate dimensions |

| Inspection | Finds defects | Reliable performance |

| Certification | Confirms compliance | Safe, compatible products |

Shengrong’s commitment to quality helps customers avoid problems during container transport. Strong corner castings reduce maintenance needs and lower the risk of accidents. The foundry’s expertise in iron casting supports safe and efficient shipping operations.

Tip: Customers should always request certification and test reports when ordering corner castings. This practice ensures that products meet safety and durability standards.

ISO Shipping Container Standards

ISO 1161 Overview

ISO 1161 sets the main standards and specifications of corner casting for every iso shipping container. This standard outlines the essential dimensions, strength, and performance requirements for corner and intermediate fittings. These requirements apply to all series 1 freight containers, except those used for air transport. By following ISO 1161, manufacturers ensure that each shipping container meets global handling and stacking needs. The standard works together with ISO 668 and ISO 1496, which cover container size and construction. When manufacturers follow these rules, they create iso shipping container units that can connect safely with cranes, trucks, and ships worldwide. The standards and specifications of corner casting help keep containers strong and reliable during transport.

ISO 1161 compliance means that every iso shipping container can be lifted, stacked, and secured using the same equipment, no matter where it travels.

Standard Dimensions

The standards and specifications of corner casting include strict size and material rules. These rules make sure that every iso shipping container uses the same type of fitting at each corner. The following list shows the main dimensions and features:

- Corner casting dimensions: 7.01 inches x 6.38 inches x 4.65 inches (178 mm x 162 mm x 118 mm)

- Hole size: about 2.5 inches (63.5 mm) in height and width

- Wall thickness: 3/4 inch

- Material: High-quality casting steel or Corten steel (such as SCW480 or SCW490)

- Weight: 11 kg per piece

- Placement: Located at all eight corners of each iso shipping container

- Usage: Enable lifting, stacking, and securing during transport

- Consistency: Dimensions remain the same for all standard and high cube containers

A standard set includes eight pieces: two top left, two top right, two bottom left, and two bottom right. These features ensure that iso corner castings fit perfectly and perform well in every shipping container.

Certification

Certification proves that a shipping container meets all international standards and specifications of corner casting. The process includes several steps:

- Design Assessment: Engineers review the design, drawings, and technical documents to check compliance with required standards.

- Prototype Testing: The design goes through testing, with results witnessed by a surveyor. Passing this step earns a design assessment.

- Factory Approval: The manufacturing site must pass a quality audit and receive approval, valid for five years with yearly checks.

- Ongoing Inspection: Surveyors inspect the factory’s processes and quality control at key points.

- Container Certification: Each shipping container receives a serial number. Inspectors review documents, witness tests, and visually check the container before marking it as certified.

| Aspect | Requirements and Details |

|---|---|

| Strength Requirements | Must handle stacking, lifting, restraint, and securing forces. |

| Material Properties | High strength, weldability, and corrosion resistance for marine use. |

| Manufacturing | Strict quality control, including chemical checks and non-destructive testing. |

| Certification | ISO 1161 certification required by transport and regulatory bodies. |

| Marking | Each casting marked for traceability and accountability. |

Certification ensures that every iso shipping container and its iso corner castings meet the highest safety and quality standards for global transport.

Practical Applications

Stacking Containers

Corner castings play a vital role in secure stacking of shipping containers. Workers align each cargo container so that the corner castings sit directly on top of those below. This method allows the weight to transfer safely through the stack. Twist locks fit into the holes of the corner castings, locking each container in place. These devices rotate 90 degrees to clamp tightly, preventing containers from shifting or tipping. The ISO 1161 standard ensures that every corner casting matches the twist locks used worldwide. This system supports stable stacks, even when ships move or trains travel over rough tracks.

Tip: Always check that twist locks are fully engaged before stacking another shipping container. This step helps prevent accidents and keeps the stack stable.

Lifting and Transport

Container transportation equipment depends on corner castings for safe lifting and movement. Cranes, forklifts, and other machines use special attachments that connect to the eight corner castings on each shipping container. The most common tool is the container spreader, which uses a hook-and-twist mechanism to lock into the castings. Operators can lift containers from any direction, thanks to the standardized design. Heavy-duty forklifts and straddle carriers also use the corner castings for secure handling. Twist locks on the lifting equipment ensure that containers do not slip or fall during movement.

- Container spreaders lock into corner castings for safe lifting.

- Cranes use twist locks to secure containers during stacking.

- Forklifts and reach stackers rely on corner castings for stable lifts.

This system improves safety and efficiency at ports, rail yards, and warehouses. It also reduces the risk of damage to the cargo container during handling.

Securing During Transit

Twist locks and corner castings work together to keep shipping containers secure during transit. When containers travel by ship, train, or truck, workers use twist locks to fasten them to the transport platform. The twist locks fit into the standardized holes of the corner castings and rotate to lock the container in place. This connection prevents movement, even in rough conditions. The heavy-duty steel of the corner castings supports the weight and pressure from above, maintaining the structural integrity of the stack.

Regular inspection of twist locks and corner castings helps prevent failures that could lead to accidents. The ISO 1161 standard ensures that all parts fit together correctly, no matter where the shipping containers travel. This universal compatibility supports safe and efficient global trade.

Note: Proper use of twist locks and regular maintenance of corner castings are essential for safe container transport.

Identification & Maintenance

Identifying Quality Castings

Quality corner castings help keep shipping containers safe and reliable. Inspectors look for smooth surfaces without cracks, pits, or sharp edges. They check for even welds that connect the casting to the container frame. A good casting has no signs of rust or deep corrosion. The holes for twist locks must be clean and shaped correctly. Inspectors measure the casting’s thickness and size to match ISO 1161 standards. If a casting shows dents, bends, or missing metal, it cannot support the container’s weight.

Tip: Always check for manufacturer markings and certification stamps. These marks show that the casting meets safety rules.

Regular inspections help spot problems early. The International Convention for Safe Containers (CSC) requires repairs for any damage that affects safety, such as cracks or corrosion. Acceptable damage limits keep containers in service while avoiding unnecessary repairs. Early detection of issues helps prevent failures and keeps cargo secure.

Compatibility Checks

Compatibility checks ensure that corner castings work with all standard equipment. Workers test if twist locks fit smoothly into the casting holes. The holes must allow twist locks to rotate and lock without sticking. If a twist lock does not fit, the casting may have the wrong shape or size. Inspectors also check that stacking cones and lifting devices connect properly.

A table can help summarize what to check:

| Checkpoint | What to Look For |

|---|---|

| Hole shape and size | Fits twist locks and stacking cones |

| Surface condition | No burrs or blockages |

| Markings | ISO 1161 compliance |

| Fit with equipment | Smooth locking and unlocking |

If a corner casting fails any of these checks, it should not be used. Using the wrong casting can cause twist locks to fail, which puts the container and cargo at risk.

Maintenance Tips

Proper maintenance keeps corner castings strong and safe. Workers should clean the castings to remove dirt, salt, and rust. They must inspect the holes for twist locks and remove any debris. If they find rust, they should use a wire brush or rust remover. After cleaning, a protective coating helps prevent new corrosion.

Inspectors should check the castings before every trip. They look for cracks, bends, or worn areas, especially around the holes for twist locks. If they find damage, they must repair or replace the casting right away. Regular inspections and repairs help containers stay stable and safe during transport. This practice reduces accidents and protects cargo from damage.

Note: Regular maintenance and inspection of corner castings and twist locks improve overall container safety. Early repairs prevent small problems from becoming serious failures.

Replacement Guidelines

Shipping container operators must know when to replace corner castings to keep containers safe and reliable. Damaged or worn castings can put cargo and workers at risk. Regular checks help spot problems early, but sometimes replacement becomes the only safe option.

When to Replace Corner Castings

Operators should consider replacement if they find any of the following issues:

- Cracks or Fractures: Even small cracks can weaken the casting. Cracks often appear near the holes or welds.

- Severe Corrosion: Rust that eats deep into the metal reduces strength. Surface rust can be cleaned, but deep pitting means replacement.

- Deformation: Bent or misshapen castings may not fit with twist locks or stacking cones. Deformation can happen after heavy impacts or drops.

- Worn or Enlarged Holes: Holes that have become too large or misshapen will not hold twist locks securely.

- Missing Material: Any loss of metal, such as chips or broken edges, makes the casting unsafe.

- Failed Welds: If the weld connecting the casting to the container frame fails, the casting must be replaced.

Tip: Always follow international standards for safety. Never use a container with a damaged or non-compliant corner casting.

Replacement Process

Operators should follow these steps to replace a corner casting:

- Inspect and Mark: Identify the damaged casting and mark it clearly.

- Prepare the Area: Remove cargo and secure the container. Clean the area around the casting.

- Cut Out the Old Casting: Use cutting tools to remove the damaged casting from the frame.

- Fit the New Casting: Position the new casting in place. Make sure it matches ISO 1161 standards.

- Weld Securely: Weld the new casting to the container frame. Use certified welders and approved welding methods.

- Inspect the Welds: Check the welds for strength and quality. Look for cracks, gaps, or weak spots.

- Test for Fit: Insert twist locks and stacking cones to ensure the new casting fits correctly.

- Document the Repair: Record the replacement in maintenance logs. Include the date, location, and inspection results.

| Step | Action Required | Why It Matters |

|---|---|---|

| Inspect & Mark | Find and mark damage | Prevents confusion |

| Prepare Area | Clean and secure container | Ensures safety |

| Remove Old Casting | Cut out damaged part | Removes weak points |

| Fit New Casting | Align and position correctly | Maintains compatibility |

| Weld Securely | Use proper welding methods | Ensures strong attachment |

| Inspect Welds | Check for defects | Guarantees safety |

| Test for Fit | Use twist locks/cones | Confirms proper function |

| Document Repair | Log all details | Supports future inspections |

Note: Only trained professionals should replace corner castings. Proper tools and safety gear are required.

Replacement Frequency

There is no set schedule for replacing corner castings. The need depends on usage, environment, and handling. Containers used in harsh conditions or heavy-duty service may need more frequent checks and replacements.

Operators should always prioritize safety. If in doubt, replace the casting rather than risk a failure during transport. Regular maintenance and timely replacement keep shipping containers strong and dependable.

Shipping container corner castings serve as vital connection points for lifting, stacking, and securing containers. Their robust steel construction and ISO standardization guarantee safe transport and global compatibility.

- High-quality materials like corten steel and strict design standards help maintain durability.

- Regular maintenance preserves the protective layer and extends lifespan.

Experts recommend sourcing certified castings from reputable foundries and verifying load-bearing specifications. For questions or professional support, readers should consult industry specialists to ensure safe and reliable container operations.

FAQ

What is the main purpose of a container corner casting?

A container corner casting provides strong points for lifting, stacking, and securing shipping containers. It connects the container to cranes, trucks, and ships. This part keeps containers stable and safe during transport.

How can someone identify a damaged corner casting?

Inspectors look for cracks, deep rust, bends, or missing metal. They check the holes for proper shape and size. Any visible damage or deformation means the casting may not be safe for use.

Are all corner castings the same size?

Standard shipping containers use corner castings with the same dimensions. ISO 1161 sets these measurements. This standardization ensures that equipment worldwide can handle containers safely and efficiently.

How often should corner castings be inspected?

Workers should inspect corner castings before every trip. Regular checks help spot problems early. Inspections keep containers safe and prevent accidents during lifting or stacking.

Can a container be used if one corner casting is damaged?

No, using a container with a damaged corner casting is unsafe. The container may not support heavy loads or connect properly with equipment. Operators must repair or replace damaged castings before use.

What materials are most common for corner castings?

Manufacturers usually use high-strength steel or ductile iron. These materials resist corrosion and handle heavy loads. Proper material choice ensures long-lasting performance in harsh environments.

Why do corner castings have different hole shapes?

Different hole shapes fit specific equipment, such as twist locks or stacking cones. The design allows for secure lifting, stacking, and locking. Each hole shape serves a unique function in container handling.

Tip: Always check for certification marks on corner castings. These marks show that the casting meets safety and quality standards.