When manufacturing professionals need to choose between casting materials, they often face the critical decision between ductile iron casting and gray iron casting. These two materials dominate the foundry industry, each offering distinct advantages for different applications. Understanding their differences can significantly impact project costs, performance, and long-term durability.

Manufacturing costs can make up over 40% of a product’s total expenses, but choosing the right casting material can help companies save up to 30% on production while improving component performance. Both ductile iron casting and gray iron casting provide unique benefits for reducing material costs, improving mechanical properties, and ensuring manufacturing efficiency.

Key Takeaways

- Gray iron casting offers excellent machinability and cost-effectiveness, making it ideal for applications requiring vibration damping and thermal stability.

- Ductile iron casting provides superior strength and ductility, perfect for components that need to withstand high stress and impact loads.

- Material selection between these casting types directly affects manufacturing costs, performance characteristics, and application suitability.

- Understanding microstructure differences helps engineers choose the optimal casting solution for specific mechanical requirements.

- Proper foundry processes and quality control ensure both casting types meet stringent industry standards and performance expectations.

Overview of Iron Casting Materials

What Are Gray Iron and Ductile Iron Castings?

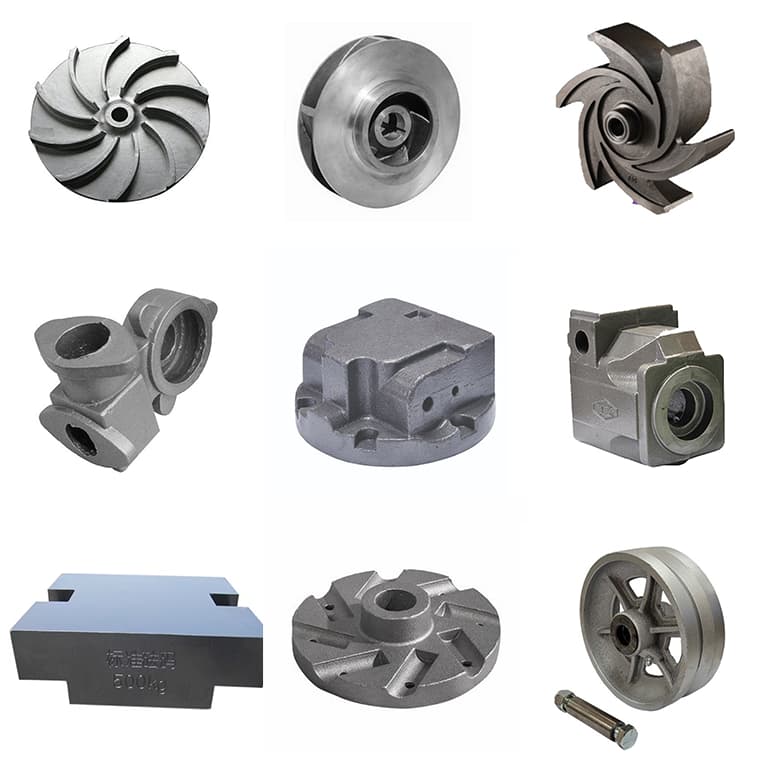

Gray iron casting and ductile iron casting represent two fundamental approaches to iron foundry work, each designed for specific engineering needs. Gray iron casting produces components with graphite flakes distributed throughout the iron matrix, creating excellent vibration damping and thermal conductivity properties. Ductile iron casting, also known as nodular iron casting, features spherical graphite nodules that provide enhanced strength and flexibility.

Both materials start with similar base compositions but achieve dramatically different properties through controlled cooling and treatment processes. The graphite structure determines the final characteristics – flake graphite in gray iron casting creates natural stress concentrators, while spherical nodules in ductile iron casting distribute stress more evenly.

Note: The choice between gray iron casting and ductile iron casting affects everything from machining costs to component lifespan, making material selection crucial for project success.

Engineers find several types of iron castings available, each designed for specific performance requirements. The table below shows common casting types and their key characteristics:

| Casting Type | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Primary Applications |

|---|---|---|---|---|

| Gray Iron | 150-350 | Not applicable | <1 | Engine blocks, pump housings |

| Ductile Iron | 400-800 | 250-550 | 2-20 | Crankshafts, gears, pipes |

| Compacted Graphite Iron | 300-500 | 200-350 | 1-6 | Diesel engine components |

| White Iron | 200-400 | High hardness | <1 | Wear-resistant parts |

These measurable standards help manufacturers select the appropriate casting material for their applications. Both gray iron casting and ductile iron casting must meet industry standards such as ASTM A48 for gray iron and ASTM A536 for ductile iron to ensure quality and performance.

How Iron Casting Works

Iron casting utilizes a controlled process where molten iron is poured into molds to create complex shapes. The key difference between gray iron casting and ductile iron casting lies in the treatment of the molten metal before pouring.

For gray iron casting:

- Molten iron contains silicon and carbon in specific ratios

- Cooling rate controls graphite flake formation

- No special additives are required during melting

For ductile iron casting:

- Magnesium or cerium is added to the molten iron

- This treatment causes graphite to form as spherical nodules

- Controlled cooling maintains the nodular structure

Manufacturers benefit from iron casting in several ways:

Gray iron casting provides excellent machinability, allowing for faster processing and lower tooling costs. The graphite flakes act as built-in lubricants during machining operations.

Ductile iron casting offers superior mechanical properties, including higher tensile strength and impact resistance compared to gray iron.

Both casting types support complex geometries that would be difficult or expensive to achieve through other manufacturing methods.

Tip: Modern foundries often use computer modeling to optimize casting designs and predict material behavior before production begins.

Recent industry developments show growing demand for both casting types:

- The global iron casting market reached $120 billion in 2023, with automotive applications driving 60% of demand

- Ductile iron casting accounts for approximately 30% of total iron casting production

- Gray iron casting remains dominant in engine block manufacturing, holding over 70% market share

- Advanced melting technologies have improved casting quality while reducing environmental impact

International standards provide additional guidance for global applications, with ISO 185 covering gray cast iron classification and various ISO specifications for steel and iron castings ensuring consistent quality across different markets.

When planning iron casting projects, manufacturers should:

- Analyze mechanical requirements to choose between gray and ductile iron casting

- Consider machining costs and post-processing needs

- Evaluate thermal properties for high-temperature applications

- Select appropriate casting techniques based on part complexity and volume requirements

Iron casting provides the flexibility, cost-effectiveness, and performance characteristics needed for modern manufacturing. Whether choosing gray iron casting or ductile iron casting, both materials support heavy-duty applications while maintaining economic viability.

Components and Properties of Iron Castings

Microstructure and Composition

The fundamental difference between gray iron casting and ductile iron casting lies in their microstructural composition. Gray iron casting contains graphite in flake form distributed throughout a ferrite or pearlite matrix. These flakes create natural stress concentrators but provide excellent thermal conductivity and vibration damping. Ductile iron casting features spherical graphite nodules embedded in the metal matrix, which distribute stress more evenly and provide superior mechanical properties.

Both casting types use similar base materials – iron, carbon, and silicon – but achieve different results through processing control. Gray iron casting typically contains 2.5-4.0% carbon and 1.0-3.0% silicon, while ductile iron casting uses similar ranges but requires magnesium treatment to form nodular graphite.

| Component Type | Gray Iron Casting | Ductile Iron Casting | Key Differences |

|---|---|---|---|

| Graphite Structure | Flake-shaped | Spherical nodules | Shape affects stress distribution |

| Carbon Content | 2.5-4.0% | 3.0-4.0% | Similar ranges, different structures |

| Silicon Content | 1.0-3.0% | 1.8-2.8% | Silicon promotes graphite formation |

| Matrix Structure | Ferrite/Pearlite | Ferrite/Pearlite/Bainite | Treatment affects final matrix |

Mechanical Properties and Performance

Gray iron casting and ductile iron casting exhibit dramatically different mechanical behaviors due to their microstructural differences. Gray iron casting typically achieves tensile strengths of 150-350 MPa with minimal elongation, making it ideal for applications where rigidity and vibration damping are priorities. Ductile iron casting delivers much higher tensile strengths of 400-800 MPa with elongation values of 2-20%, providing excellent toughness and impact resistance.

The graphite structure directly influences these properties. In gray iron casting, flake graphite creates weak points that limit tensile strength but enhance thermal conductivity and machinability. In ductile iron casting, spherical nodules act as stress distributors, dramatically improving ductility and fatigue resistance.

Tip: When selecting between casting types, consider that gray iron casting excels in compression while ductile iron casting performs better under tension and impact loading.

Surface Finishes and Treatments

Surface treatments for both gray iron casting and ductile iron casting focus on enhancing durability, appearance, and performance characteristics. Gray iron casting naturally provides good surface finishes due to its graphite content, which aids in machining operations. Common treatments include phosphating for corrosion resistance and painting for aesthetic purposes.

Ductile iron casting can receive various surface treatments including heat treatment to modify mechanical properties, coating applications for corrosion protection, and specialized finishes for specific environments. Heat treatment options include annealing, normalizing, and quenching and tempering to achieve desired hardness levels.

Surface quality testing shows that proper casting techniques can achieve surface roughness values below 6.3 μm Ra for both materials, suitable for most engineering applications. Advanced coating systems can extend service life beyond 20 years in corrosive environments, while proper heat treatment can increase hardness by 50-100% when required.

Modern foundry practices ensure consistent quality through:

- Automated molding systems for dimensional accuracy

- Computer-controlled melting for consistent chemistry

- Non-destructive testing to verify internal soundness

- Statistical process control for quality assurance

Manufacturers gain significant advantages from understanding these material properties. Gray iron casting provides cost-effective solutions for applications requiring thermal stability and vibration control, while ductile iron casting delivers superior performance for high-stress mechanical components.

Benefits in Manufacturing Applications

Machinability and Processing

Gray iron casting delivers exceptional machinability advantages that significantly reduce manufacturing costs and processing time. The graphite flakes in gray iron act as built-in chip breakers and provide natural lubrication during cutting operations. This characteristic allows for higher cutting speeds and longer tool life compared to other materials. Machining operations on gray iron casting typically achieve surface finishes of 1.6-3.2 μm Ra without specialized tooling.

Ductile iron casting requires more careful machining due to its higher strength and ductility, but modern cutting tools and techniques have made processing efficient. While tool wear rates are higher than with gray iron, the superior mechanical properties often justify the additional machining costs. Manufacturers benefit from shorter cycle times in applications where gray iron casting is suitable, while ductile iron casting provides better performance in demanding applications.

Studies demonstrate that gray iron casting can reduce machining time by 20-40% compared to steel alternatives, while maintaining dimensional accuracy within ±0.1mm tolerances. Tool life improvements of 2-3x are common when machining gray iron versus ductile iron, resulting in lower per-part manufacturing costs.

Specialized tooling for both casting types optimizes production efficiency. Advanced cutting fluids enhance surface finish and dimensional control. Computer-controlled machining ensures consistent quality across production runs.

Cost Effectiveness and Material Efficiency

Both gray iron casting and ductile iron casting offer significant cost advantages over alternative materials in appropriate applications. Gray iron casting provides the lowest raw material costs among cast iron types, making it ideal for high-volume production where strength requirements are moderate. The material’s excellent fluidity during casting allows for thin-wall sections and complex geometries that minimize material usage.

Ductile iron casting, while more expensive than gray iron, often replaces steel components at lower total costs when considering manufacturing, machining, and assembly factors. The material’s castability eliminates many welding and fabrication steps required for steel alternatives.

Tip: Component consolidation through casting design can reduce assembly costs by 30-50% while improving structural integrity.

Durability and Performance

Gray iron casting excels in applications requiring thermal stability, vibration damping, and wear resistance. The graphite flakes provide excellent thermal conductivity, making gray iron ideal for applications like engine blocks and brake components where heat dissipation is critical. Compressive strength values of 500-1400 MPa make gray iron suitable for heavily loaded static applications.

Ductile iron casting delivers superior performance in dynamic loading conditions, with fatigue limits 2-3 times higher than gray iron. The material’s combination of strength and ductility makes it suitable for crankshafts, gears, and other rotating machinery components. Impact resistance of ductile iron casting is 5-10 times greater than gray iron, providing reliability in shock loading situations.

Long-term performance studies show that properly designed gray iron components can operate for decades in stable thermal environments, while ductile iron components maintain structural integrity through millions of stress cycles. Both materials support sustainable manufacturing by offering 20-30 year service lives in appropriate applications.

An iron casting foundry system provides manufacturers with versatile solutions for complex engineering challenges. Whether selecting gray iron casting for cost-effective thermal applications or ductile iron casting for high-performance mechanical components, both materials deliver proven reliability and manufacturing efficiency.

Iron Casting Types and Selection

When manufacturers evaluate casting options, they encounter various iron types designed for specific performance requirements. Each casting variant offers unique characteristics that affect application suitability, manufacturing costs, and long-term performance. Understanding these differences helps engineers make informed material selections.

Gray Iron Casting Variants

Gray iron casting comes in several grades classified by tensile strength and application requirements. Class 20 gray iron (150 MPa tensile strength) suits low-stress applications like decorative components and small housings. Class 30-35 grades (210-250 MPa) work well for automotive engine blocks and pump casings. High-strength gray iron casting (Class 40-60) achieves 280-420 MPa tensile strength for more demanding applications.

Specialized gray iron formulations include:

- High-silicon gray iron for improved corrosion resistance

- Ni-hard gray iron for enhanced wear resistance

- Alloyed grades for elevated temperature service

- Fine-grain gray iron for better surface finish

Tip: Gray iron casting grades are often selected based on section thickness, with thinner sections requiring higher-grade materials for adequate strength.

Ductile Iron Casting Classifications

Ductile iron casting uses a different classification system based on tensile strength, yield strength, and elongation properties. Grade 60-40-18 provides 414 MPa tensile strength, 276 MPa yield strength, and 18% elongation for general-purpose applications. Grade 80-55-06 delivers 552 MPa tensile strength with moderate ductility for automotive components. High-strength grades like 100-70-03 achieve 689 MPa tensile strength for demanding mechanical applications.

A comparison table helps illustrate the range of available options:

| Grade Type | Gray Iron Casting | Ductile Iron Casting | Key Applications |

|---|---|---|---|

| Low Strength | Class 20 (150 MPa) | 60-40-18 (414 MPa) | Housing, brackets, low-stress parts |

| Medium Strength | Class 35 (250 MPa) | 80-55-06 (552 MPa) | Engine blocks, machinery frames |

| High Strength | Class 50 (350 MPa) | 100-70-03 (689 MPa) | Crankshafts, high-stress components |

Advanced Casting Solutions

Modern foundries offer specialized treatments and alloy modifications to enhance both gray iron casting and ductile iron casting performance. Austempered ductile iron (ADI) heat treatment can double the strength of standard ductile iron while maintaining good ductility. Compacted graphite iron bridges the gap between gray and ductile iron, offering improved strength over gray iron while maintaining superior thermal conductivity.

Recent material innovations include:

- Vermicular graphite iron for diesel engine applications

- High-silicon ductile iron for corrosion resistance

- Bainitic ductile iron for wear applications

- Lightweight hollow casting designs for weight reduction

Note: Advanced casting solutions often require specialized foundry capabilities and quality control processes to ensure consistent results.

Environmental considerations increasingly influence material selection. Both gray iron casting and ductile iron casting offer excellent recyclability, with scrap iron content often exceeding 90% in new castings. Life cycle assessments show that iron castings typically have lower environmental impacts than alternative materials when considering manufacturing energy, transportation, and end-of-life recycling.

Engineers should consider these factors when selecting casting materials:

- Load requirements and service conditions

- Manufacturing volume and cost targets

- Machining and finishing requirements

- Environmental and sustainability goals

- Foundry capabilities and quality systems

Professional consultation ensures optimal material selection for specific applications. Experienced foundry partners can recommend the most suitable gray iron casting or ductile iron casting grade while optimizing designs for manufacturability and performance.

Selection Guidelines and Quality Considerations

Choosing the Right Casting Material

Material selection between gray iron casting and ductile iron casting requires careful analysis of application requirements, performance criteria, and cost considerations. Engineers should evaluate several key factors before making their selection.

Load analysis forms the foundation of material choice. Gray iron casting performs excellently under compressive loads and provides superior vibration damping for applications like machine tool bases and engine blocks. Ductile iron casting handles tensile loads, impact forces, and cyclic stresses more effectively, making it suitable for crankshafts, connecting rods, and structural components.

Consider these selection criteria:

- Mechanical Requirements: Tensile strength, yield strength, elongation, and fatigue resistance

- Operating Environment: Temperature range, corrosive conditions, and thermal cycling

- Manufacturing Factors: Machining requirements, casting complexity, and production volume

- Economic Considerations: Material costs, processing expenses, and total lifecycle value

Service Conditions: High-temperature applications benefit from gray iron’s thermal conductivity, while shock-loading conditions require ductile iron’s impact resistance.

Design Complexity: Complex geometries with thin walls favor gray iron’s superior fluidity, while thick sections benefit from ductile iron’s feeding characteristics.

Quality Control and Standards

Both gray iron casting and ductile iron casting must meet rigorous quality standards to ensure reliable performance. Industry specifications provide guidelines for chemical composition, mechanical properties, and testing procedures.

Key quality control measures include:

- Chemical analysis to verify composition requirements

- Mechanical testing for tensile strength, hardness, and impact resistance

- Metallographic examination to assess microstructure quality

- Non-destructive testing to detect internal defects

ASTM standards govern iron casting quality:

- ASTM A48 specifies requirements for gray iron casting

- ASTM A536 covers ductile iron casting specifications

- Additional standards address specialized applications and testing methods

Professional foundries implement comprehensive quality systems including statistical process control, traceability systems, and continuous improvement programs. These measures ensure consistent material properties and dimensional accuracy across production runs.

Maintenance and Performance Optimization

Proper application of gray iron casting and ductile iron casting requires understanding of material limitations and performance characteristics. Gray iron components excel in stable thermal environments but require protection from shock loads. Ductile iron components handle dynamic loading well but may require heat treatment for optimal hardness in wear applications.

Performance optimization strategies include:

- Heat treatment selection to achieve desired mechanical properties

- Surface treatments for enhanced corrosion or wear resistance

- Design modifications to optimize stress distribution

- Preventive maintenance schedules based on application severity

Tip: Regular inspection programs help identify potential issues before component failure occurs, maximizing equipment uptime and safety.

Long-term performance studies demonstrate that both casting types provide decades of reliable service when properly applied. Gray iron casting maintains dimensional stability and vibration damping properties throughout its service life. Ductile iron casting retains strength and ductility under normal operating conditions while providing excellent fatigue resistance.

Successful implementation of either gray iron casting or ductile iron casting depends on matching material properties to application requirements. When working with an experienced iron casting foundry, manufacturers can optimize designs, select appropriate materials, and implement quality systems that ensure long-term success. Shengrong provides comprehensive foundry services that help clients achieve optimal results through proper material selection, quality control, and technical support.

Frequently Asked Questions

What is the main difference between gray iron casting and ductile iron casting?

The primary difference lies in graphite structure – gray iron casting contains flake graphite that provides excellent machinability and thermal properties, while ductile iron casting features spherical graphite nodules that deliver superior strength and ductility.

How do you choose between gray iron and ductile iron casting for a project?

Selection depends on mechanical requirements, operating conditions, and cost considerations. Gray iron casting works best for applications requiring vibration damping, thermal conductivity, and cost effectiveness. Ductile iron casting suits applications needing high strength, impact resistance, and flexibility.

Can both casting types handle high-temperature applications?

Yes, but with different advantages. Gray iron casting provides better thermal conductivity and dimensional stability at elevated temperatures. Ductile iron casting maintains strength at higher temperatures but may require heat treatment for optimal performance.

What are the typical cost differences between these casting materials?

Gray iron casting typically costs 10-20% less than ductile iron casting in raw material costs. However, total project costs depend on machining requirements, post-processing needs, and performance requirements that might favor one material over another.

Are there environmental benefits to choosing iron castings?

Both gray iron casting and ductile iron casting offer excellent recyclability with scrap content often exceeding 90%. Iron castings typically have lower lifecycle environmental impacts compared to alternative materials when considering manufacturing energy and end-of-life recycling.