EN-GJL-250 represents a widely used grade of grey cast iron specified by the EN 1561 standard. This iron grade plays a critical role in casting applications where reliability and performance matter. Engineers and manufacturers select EN-GJL-250 cast iron for several reasons:

- Excellent wear resistance

- Good thermal conductivity

- High damping capacity

- High machinability

- Cost-effectiveness

A thorough understanding of its composition, properties, and optimal practices ensures successful design, procurement, and production of high-quality cast components.

Key Takeaways

- EN-GJL-250 is a popular grade of grey cast iron known for its strength and machinability.

- This material offers excellent wear resistance, making it ideal for components that face heavy use.

- EN-GJL-250 has good thermal conductivity, which helps in heat dissipation for engine parts and brake discs.

- Engineers should always check the EN-GJL-250 chemical composition to ensure reliable performance in casting.

- The microstructure of EN-GJL-250 includes lamellar graphite, which provides good vibration damping but can also lead to brittleness.

- Cost-effectiveness is a major advantage of EN-GJL-250, making it a preferred choice for many industries.

- Common defects in EN-GJL-250 castings include hot tears and cold shuts, which can be minimized with proper techniques.

- Regular inspection and quality control are essential to maintain the performance and reliability of EN-GJL-250 castings.

EN-GJL-250 Overview

Definition

EN-GJL-250 stands as a prominent grade of grey cast iron defined by the EN 1561 standard. This material, often referred to as GG25 in the DIN 1691 system, belongs to the family of gray irons known for their unique graphite structure. EN-GJL-250 cast iron offers a balance between strength, machinability, and cost, making it a preferred choice for many industrial applications. Engineers and manufacturers rely on this grade for its predictable performance in Grey Iron Casting, especially when designing components that require good vibration damping and thermal conductivity.

Standards and Equivalents

EN-GJL-250 aligns with several international standards, ensuring global compatibility for design and procurement. Understanding the EN-GJL-250 material equivalent options is crucial for engineers working on international projects. The table below highlights its key properties and equivalent grades across different countries:

| Property/Grade | EN-GJL-250 | Equivalent Grades |

|---|---|---|

| Density | 7.20 g/cm³ | GG25 (DIN), ASTM A48 Class 40, FGL250 (UNE) |

This broad range of equivalents allows engineers to specify EN-GJL-250 material equivalent grades confidently, knowing that the material will meet similar performance expectations worldwide. The consistent mechanical properties, such as tensile strength and density, support its use in critical gray iron casting projects.

Microstructure

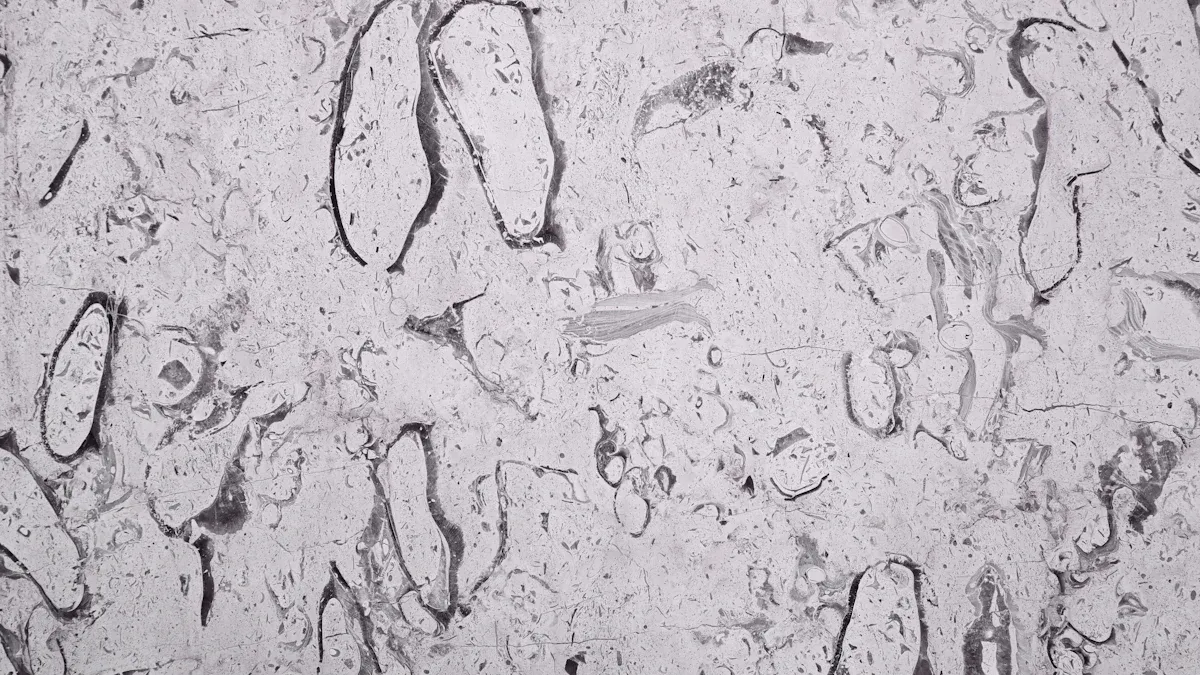

The microstructure of EN-GJL-250 features lamellar graphite distributed throughout a pearlitic matrix. This structure defines many of the material’s key characteristics. The table below summarizes the main aspects:

| Aspect | Description |

|---|---|

| Microstructure | EN-GJL-250 contains lamellar graphite, which acts as stress concentrators. |

| Mechanical Strength | The lamellar graphite leads to lower mechanical strength compared to spheroidal graphite irons. |

| Pearlite Content | High pearlite content increases hardness but also makes the material more brittle. |

The lamellar graphite in EN-GJL-250 gray iron provides excellent vibration damping and machinability. However, it also introduces brittleness, which limits the material’s use in high-stress environments. The high pearlite content enhances hardness, making EN-GJL-250 suitable for applications where wear resistance is important. Understanding the EN-GJL-250 chemical composition and microstructure helps engineers select the right grade for their specific needs and ensures that material properties align with performance requirements.

EN-GJL-250 Chemical Composition

Main Elements

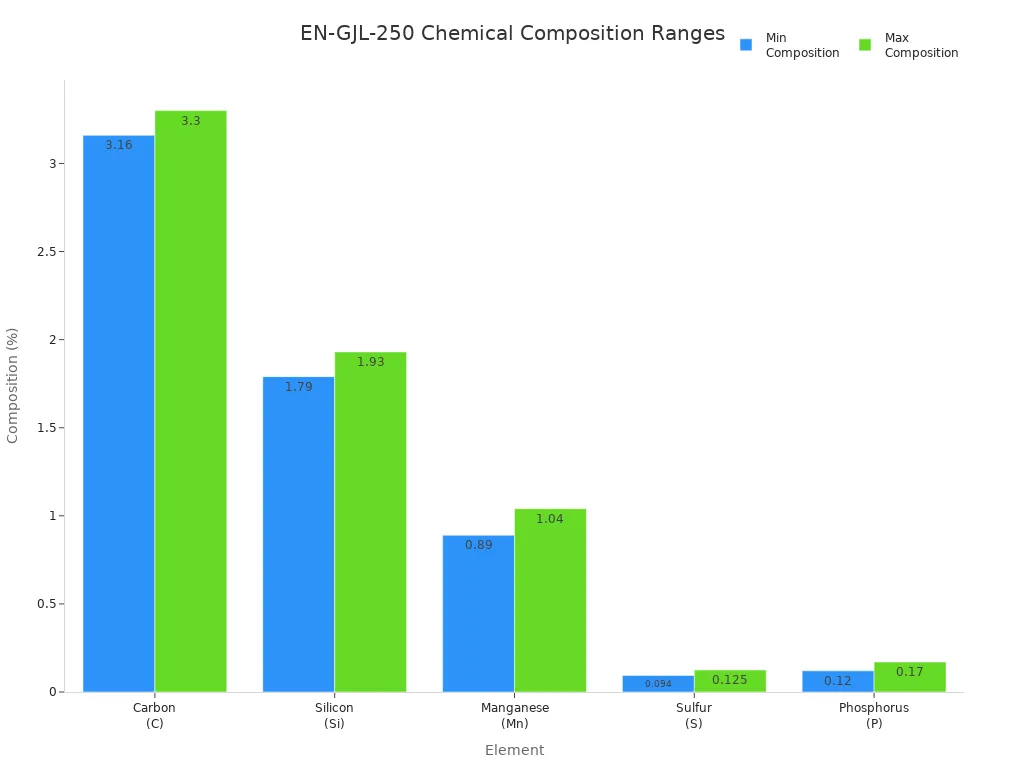

EN-GJL-250 cast iron stands out in the field of cast iron due to its carefully controlled chemical makeup. The EN 1561 standard specifies the ranges for the main elements that define the performance of this iron grade. Engineers rely on these values to predict the behavior of EN-GJL-250 in Grey Iron Casting applications. The table below summarizes the typical composition ranges:

| Element | Composition Range (%) |

|---|---|

| Carbon (C) | 3.16 – 3.30 |

| Silicon (Si) | 1.79 – 1.93 |

| Manganese (Mn) | 0.89 – 1.04 |

| Sulfur (S) | 0.094 – 0.125 |

| Phosphorus (P) | 0.120 – 0.170 |

Carbon and silicon serve as the primary elements in the EN-GJL-250 chemical composition. Carbon forms the graphite structure, which gives cast iron its characteristic properties. Silicon promotes the formation of graphite and influences the matrix structure. Manganese helps control the pearlite content, which affects hardness and strength. The balance of these elements ensures that EN-GJL-250 material properties meet the requirements for vibration damping, machinability, and wear resistance.

Tip: Engineers should always verify the chemical composition when selecting EN-GJL-250 material equivalent grades for international projects. Consistent composition guarantees predictable performance in cast iron components.

Impurities

Impurities such as phosphorus and sulfur play a significant role in determining the final properties of EN-GJL-250. Although present in small amounts, these elements can impact the mechanical behavior of cast iron. Increased phosphorus levels enhance wear and corrosion resistance, which benefits components exposed to harsh environments. However, higher phosphorus also leads to brittle fracture during tensile testing, reducing the material’s toughness.

Sulfur, another impurity, affects the formation of iron sulfide inclusions. These inclusions can weaken the structure and decrease ductility. Manufacturers must control sulfur and phosphorus levels to maintain the desired balance between hardness and brittleness in material properties.

The careful management of impurities ensures that EN-GJL-250 cast iron maintains its reputation for reliability in Grey Iron Casting. By understanding the relationship between EN-GJL-250 chemical composition and performance, engineers can optimize designs and select the best material equivalent for their specific needs.

EN-GJL-250 Material Properties

Understanding the material characteristics of EN-GJL-250 is essential for engineers and manufacturers who work with Grey Iron Casting. These EN-GJL-250 material properties determine the performance, durability, and suitability of cast components in various applications. The following sections provide a detailed overview of the mechanical, physical, and chemical properties that define this iron grade.

Mechanical Properties

Mechanical properties play a critical role in the selection of EN-GJL-250 for casting projects. These characteristics influence the strength, durability, and machinability of the final product.

Tensile Strength

EN-GJL-250 offers a high level of strength compared to other grades of grey cast iron. The tensile strength measures the maximum stress the material can withstand while being stretched or pulled before breaking. This property is vital for components that experience significant loads during operation.

| Property | Value Range |

|---|---|

| Tensile strength | 250-300 MPa |

When compared to other common grades, EN-GJL-250 stands out for its balance between strength and machinability:

| Material Designation | Tensile Strength (MPa) |

|---|---|

| EN-GJL-200 | 200-300 |

| EN-GJL-250 | 250-300 |

| EN-GJL-300 | 300-400 |

This strength makes EN-GJL-250 suitable for applications that demand durability and resistance to deformation, such as engine blocks and machinery housings.

Yield Strength

Yield strength indicates the stress at which a material begins to deform permanently. For EN-GJL-250, the yield strength typically ranges from 162 to 195 MPa.

| Property | Value Range |

|---|---|

| Yield strength | 162 – 195 MPa |

Although the yield strength is lower than the tensile strength, it still provides sufficient durability for most casting applications. This property ensures that components maintain their shape under normal operating conditions.

Hardness

Hardness reflects the material’s resistance to indentation and wear. EN-GJL-250 exhibits a hardness range of 152 to 285 HV (Vickers Hardness), which translates to 190 to 240 BH (Brinell Hardness).

| Property | Value Range |

|---|---|

| Hardness (Vickers) | 152 – 285 HV |

| Hardness (Brinell) | 190 – 240 BH |

A higher hardness value improves wear resistance but can make machining more challenging, especially for thin-walled castings. Engineers must consider this when designing components that require both durability and ease of manufacturing.

Note: The mechanical EN-GJL-250 material properties, including its strength and hardness, directly impact its performance in Grey Iron Casting. These properties ensure that castings can withstand operational stresses and maintain long-term reliability.

Physical Properties

Physical properties describe how EN-GJL-250 behaves under various environmental conditions. These characteristics influence the material’s performance in heat transfer, vibration damping, and overall stability.

Density

EN-GJL-250 has a typical density of 7.20 g/cm³. This value ensures that cast components possess the necessary mass and structural integrity for demanding applications.

Thermal Conductivity

Thermal conductivity measures the material’s ability to transfer heat. EN-GJL-250 demonstrates excellent thermal conductivity, ranging from 44 to 51 W/m.°C. This property makes it ideal for components that require efficient heat dissipation, such as brake discs and engine parts.

| Property | Value Range |

|---|---|

| Thermal conductivity | 44-51 W/m.°C |

Damping

Damping capacity refers to the material’s ability to absorb vibrations. EN-GJL-250 excels in this area due to its unique graphite structure. High damping reduces noise and vibration in machinery, improving operational comfort and extending equipment life.

Tip: The physical properties of EN-GJL-250, including its density, thermal conductivity, and damping capacity, make EN-GJL-250 material equivalent grades a preferred choice for industries that demand both performance and reliability.

Chemical Properties

Chemical properties determine how EN-GJL-250 reacts to environmental factors such as moisture, chemicals, and high temperatures. These characteristics affect the longevity and maintenance requirements of cast components.

Corrosion Resistance

EN-GJL-250 is not inherently resistant to corrosion. The corrosion current and rate are significantly higher than those of coated samples. This means that unprotected castings may degrade faster in harsh environments.

| Property | EN-GJL-250 | Coated Samples |

|---|---|---|

| Corrosion Current | Higher | Lower |

Engineers often apply protective coatings to improve the corrosion resistance of EN-GJL-250 castings, especially for outdoor or marine applications.

Oxidation

Oxidation behavior in EN-GJL-250 is pronounced, especially at elevated temperatures. The material forms an outer oxide layer, which can provide some protection but may not be sufficient for all environments.

| Property | EN-GJL-250 | Coated Samples |

|---|---|---|

| Oxidation Behavior | Pronounced oxidation observed | High resistance due to outer oxide layer |

Alert: For applications that require components to be resistant to corrosion and oxidation, engineers should consider additional surface treatments or select an EN-GJL-250 material equivalent with enhanced chemical properties.

How Material Properties Impact Casting Performance

The combination of mechanical, physical, and chemical characteristics makes EN-GJL-250 a versatile choice for Grey Iron Casting. Its high level of strength and durability support demanding applications, while its excellent thermal conductivity and damping capacity enhance performance in automotive and industrial settings. However, the lack of inherent corrosion resistance means that additional protection may be necessary for certain environments. By understanding the EN-GJL-250 chemical composition and EN-GJL-250 material properties, engineers can optimize designs and ensure reliable, long-lasting cast components.

Advantages of EN-GJL-250 Castings

EN-GJL-250 castings offer several advantages that make them a preferred choice for engineers and manufacturers in a wide range of industries. These benefits stem from the unique composition and material characteristics, which support reliable performance in Grey Iron Casting applications.

Cost-Effectiveness

Cost-effectiveness remains one of the most significant advantages of EN-GJL-250 castings. Manufacturers often select this material for its ability to deliver high durability at a lower price point compared to alternatives. The following table highlights how EN-GJL-250 cast iron castings compare with other materials used for similar applications:

| Material Type | Cost Comparison | Advantages | Disadvantages |

|---|---|---|---|

| EN-GJL-250 Cast Iron | Lower cost | Good durability, withstands heavy loads | Susceptible to corrosion |

EN-GJL-250 castings provide a balance between affordability and performance. They withstand heavy loads and offer long service life, which reduces replacement costs. Many industries rely on EN-GJL-250 castings for large-scale production because of their cost-effectiveness.

Manufacturers can optimize budgets by choosing EN-GJL-250 castings for components that do not require extreme corrosion resistance.

Machinability

Machinability is another key advantage of EN-GJL-250 castings. The graphite structure and controlled composition allow for efficient machining processes. Studies show that coated CBN cutting tools experience lower tool wear when machining EN-GJL-250 compared to other materials. Optimal machining parameters include a cutting speed of 660 m/min, a feed rate of 0.13 mm/rev, and a depth of cut of 0.232 mm. These settings help minimize surface roughness and cutting forces.

Engineers benefit from the favorable machinability of EN-GJL-250 castings. They can achieve precise dimensions and smooth finishes with less tool replacement. This advantage supports high productivity and reduces manufacturing costs. Material equivalent grades also maintain consistent machinability, which simplifies process planning for global projects.

Thermal Performance

Thermal performance sets EN-GJL-250 castings apart in applications that demand efficient heat transfer. The material properties include high thermal conductivity, which benefits components exposed to rapid temperature changes. Using chromite sand for molding further enhances the thermal performance of EN-GJL-250 castings. This improvement affects cooling rates during casting and influences the microstructure, especially the formation of martensite and pearlite.

Superior thermal performance allows EN-GJL-250 castings to maintain mechanical strength and hardness in demanding environments. Automotive and machinery industries often use EN-GJL-250 castings for engine blocks, brake discs, and other parts that require reliable heat dissipation. The combination of thermal conductivity and stable microstructure ensures long-term durability.

EN-GJL-250 castings deliver consistent results in applications where thermal management is critical.

Limitations of EN-GJL-250

Brittleness

Grey cast iron EN-GJL-250 displays significant brittleness, which engineers must consider during component design. The material shows very low plastic deformation, making it prone to cracking under sudden impact or thermal stress. This brittleness can reduce the reliability of cast parts, especially when exposed to fluctuating temperatures or dynamic loads. The behavior of EN-GJL-250 differs in tension and compression. While its compressive strength matches that of low and medium carbon steel, its tensile strength remains lower, increasing the risk of fracture in tension-loaded applications.

- Grey cast iron EN-GJL-250 is very brittle and exhibits minimal plastic deformation.

- Brittleness can compromise component reliability, particularly under thermal stress.

- The material performs better under compression than tension.

Designers working with Grey Iron Casting must account for these brittleness concerns. They often select material equivalent grades with improved ductility for critical applications. Understanding EN-GJL-250 material properties helps engineers predict failure modes and choose appropriate safety factors.

Wear Resistance

The wear resistance of EN-GJL-250 depends on its microstructure and the presence of coatings. Tests comparing EN-GJL-250 to abrasion-resistant steel, such as Hardox® 400, revealed that coated EN-GJL-250 castings can perform competitively in abrasive environments. For example, the Eutalloy® BronzoChrom 10185 coating reduced wear intensity by 13% under abrasive conditions. The microstructure, especially the fraction of graphite, plays a key role in wear resistance. Studies on compacted graphite iron grades showed that variations in hardness and graphite content significantly affect performance.

- Coated EN-GJL-250 castings demonstrate lower wear intensity in abrasive environments.

- Microstructure differences, such as graphite fraction, influence wear resistance.

- Hardness variations among cast iron grades impact durability.

Engineers must evaluate the composition and consider surface treatments to enhance wear resistance. Selecting the right EN-GJL-250 material equivalent ensures optimal performance in demanding applications.

Stress Limitations

EN-GJL-250 faces limitations when subjected to high stress or cyclic loading. The lamellar graphite structure, while beneficial for vibration damping, acts as a stress concentrator. This feature increases the likelihood of crack initiation and propagation under repeated or extreme loads. Components made from EN-GJL-250 may not withstand severe mechanical stress as effectively as ductile iron or steel. For applications involving heavy loads or dynamic forces, engineers often choose alternative materials or reinforce designs to mitigate stress-related failures.

Note: Understanding material properties and their impact on stress limitations allows manufacturers to optimize casting designs and improve service life.

Engineers should always assess the operational environment and loading conditions before specifying EN-GJL-250 for Grey Iron Casting. Careful selection of equivalent grades and attention to EN-GJL-250 chemical composition can help address these stress limitations.

EN-GJL-250 Castings Applications

Automotive

Automotive manufacturers rely on EN-GJL-250 for a wide range of components. This grade of grey cast iron meets the performance requirements for engine blocks, cylinder heads, brake discs, and clutch housings. The material composition provides good strength and hardness, making it suitable for parts that must withstand moderate mechanical stress. Machinability remains a key advantage, allowing precise shaping of complex automotive parts. The material’s excellent damping capacity reduces vibration and noise, which improves driving comfort and extends the lifespan of critical components.

Automotive engineers select EN-GJL-250 material equivalent grades for their cost-effectiveness and versatility. The thermal conductivity of this iron grade ensures efficient heat transfer, which is essential for engine cooling and brake performance. Although EN-GJL-250 cast iron is susceptible to corrosion, protective coatings can enhance its durability in harsh environments. The following table summarizes the main performance attributes for automotive applications:

| Property | Description |

|---|---|

| Strength and Hardness | Good strength and hardness properties suitable for moderate strength needs. |

| Machinability | Good machinability for ease of machining operations. |

| Damping Capacity | Excellent damping capacity for vibration and noise reduction. |

| Wear Resistance | Moderate wear resistance for components subjected to wear. |

| Thermal Conductivity | Good thermal conductivity for efficient heat transfer. |

| Corrosion Resistance | Susceptible to corrosion but can be enhanced with coatings. |

| Versatility | Used in various industries including automotive. |

| Cost-Effective | Generally cost-effective compared to other materials. |

Automotive castings made from EN-GJL-250 often feature wall thicknesses up to 30 mm, supporting robust designs for stressed parts.

Machinery

Machinery manufacturers use EN-GJL-250 in a variety of applications, including gearboxes, pump housings, and bearing supports. The material delivers excellent strength and durability, which are essential for reliable operation in industrial settings. The uniform structure and high precision of Grey Iron Casting allow for consistent performance in machinery components. Machinability enables manufacturers to produce intricate shapes and tight tolerances, reducing production time and costs.

Material equivalent grades are favored in machinery production due to their ability to withstand harsh operating conditions. Heavy-duty machinery benefits from the toughness and vibration-damping properties of this iron grade. The material’s moderate hardness and wear resistance ensure long service life, even in environments with frequent mechanical stress. Engineers often choose EN-GJL-250 for machinery parts that require both strength and cost efficiency.

Machinery applications also include components for pumps, compressors, and hydraulic systems. The EN-GJL-250 chemical composition supports stable performance under varying loads and temperatures. Manufacturers appreciate the balance between machinability and durability, which simplifies maintenance and replacement of worn parts.

Construction

Construction projects utilize EN-GJL-250 castings for structural supports, valve bodies, and pipe fittings. The dense structure and moderate hardness of this EN-GJL-250 material provide reliable sealing and corrosion resistance, especially in chemical transport systems. Material properties such as vibration damping and toughness make it suitable for construction machinery and infrastructure components.

Engineers select equivalent grades for their ability to maintain uniform structure and high precision. The material’s heat dissipation and cost-effectiveness support lightweight designs and complex shapes in construction applications. Wall thicknesses up to 30 mm allow for robust castings that withstand heavy loads and environmental stress.

Construction castings made from EN-GJL-250 offer a combination of durability, machinability, and resistance to wear, making them a preferred choice for demanding projects.

Other Uses

EN-GJL-250 finds application in many industries beyond automotive, machinery, and construction. Engineers and manufacturers value this grade for its versatility in Grey Iron Casting. The unique composition and material characteristics support reliable performance in diverse environments.

Municipal Infrastructure

Municipal projects often require durable and cost-effective components. EN-GJL-250 cast iron serves in the production of manhole covers, drainage grates, and street furniture. These castings withstand heavy loads and frequent traffic. The material’s high damping capacity reduces noise from vehicles passing over covers and grates.

Agricultural Equipment

Farm machinery relies on robust parts that resist wear and vibration. Material equivalent grades provide the necessary hardness and machinability for plow shoes, gear housings, and pump bodies. The graphite structure in Grey Iron Casting absorbs shocks, protecting equipment from damage during field operations.

Energy Sector

Power generation facilities use EN-GJL-250 for turbine housings, generator bases, and valve bodies. The material’s thermal conductivity ensures efficient heat dissipation. Engineers select this grade for components exposed to temperature fluctuations and mechanical stress.

Railway and Transportation

Railway systems require cast iron parts that offer stability and vibration damping. EN-GJL-250 supports the manufacture of brake shoes, coupler components, and track fittings. The material’s predictable performance and cost-effectiveness make it suitable for large-scale infrastructure projects.

General Industrial Uses

Many factories use EN-GJL-250 in conveyor systems, machine bases, and counterweights. The composition provides a balance of strength and machinability. Manufacturers benefit from the ability to produce castings with wall thicknesses up to 30 mm, supporting heavy-duty applications.

| Application Area | Typical Components | Key Benefits |

|---|---|---|

| Municipal Infrastructure | Manhole covers, grates, furniture | Load resistance, noise reduction |

| Agriculture | Plow shoes, gear housings, pumps | Wear resistance, shock absorption |

| Energy Sector | Turbine housings, valve bodies | Heat dissipation, durability |

| Railway/Transport | Brake shoes, couplers, fittings | Vibration damping, reliability |

| General Industry | Machine bases, counterweights | Machinability, strength |

Note: EN-GJL-250 material equivalent grades allow manufacturers to source castings globally while maintaining consistent quality and performance.

Engineers continue to explore new uses for EN-GJL-250 in Grey Iron Casting. The combination of favorable properties and adaptable composition ensures that this grade remains a staple in many sectors. Manufacturers should assess specific requirements for each application to maximize the benefits of EN-GJL-250 castings.

Casting Process for EN-GJL-250

Methods for Grey Iron Castings

Manufacturers use several methods to produce EN-GJL-250 grey iron castings. Each method affects the final quality and performance of the component. The table below summarizes the main casting methods and their impact on component quality:

| Casting Method | Effect on Component Quality |

|---|---|

| Resin Sand Molding | Affects dimensional accuracy and surface finish. |

| Shell Molding | Enhances surface finish and dimensional precision. |

| Green Sand Casting | Cost-effective but may compromise surface quality. |

| Lost Wax Investment Casting | Provides high precision and excellent surface finish. |

Resin sand molding influences both the accuracy and the appearance of the finished casting. Shell molding improves surface finish and precision, making it suitable for parts that require tight tolerances. Green sand casting offers a budget-friendly option, but it may result in rougher surfaces. Lost wax investment casting delivers the highest precision and best surface finish, ideal for complex shapes.

Process Parameters

Foundries must control several process parameters to achieve high-quality EN-GJL-250 grey iron castings. The following steps help maintain consistency and reduce defects:

- Maintain consistent sand quality throughout the casting process. Good sand prevents defects and supports efficient production.

- Optimize cooling to prevent deformation. Proper cooling techniques help avoid warping and cracking.

- Prioritize regular equipment maintenance. Reliable equipment reduces defect rates and downtime.

- Use advanced shakeout technology for efficient sand removal. Clean castings improve overall quality.

- Adjust vibration controls for precision. Fine-tuning vibration ensures uniform castings and minimizes defects.

- Employ attrition mills to improve sand quality. Enhanced sand consistency leads to better grain size and casting results.

These parameters play a critical role in producing EN-GJL-250 castings with the desired mechanical and physical properties. Foundries that follow these steps consistently deliver reliable grey iron castings for various industries.

Tip: Careful control of process parameters ensures that EN-GJL-250 castings meet strict quality standards and perform well in demanding applications.

Quality Control

Quality control measures guarantee the consistency and reliability of EN-GJL-250 grey iron castings. Foundries implement several strategies to monitor and improve casting quality:

| Quality Control Measure | Description |

|---|---|

| Regular Sampling | Checks on size, appearance, and physical properties during production. |

| Multiple Inspections | Different inspectors conduct multiple sampling inspections on final products. |

| Advanced Machining Techniques | New machining methods achieve tighter tolerances and superior surface finishes. |

Advanced machining techniques have been selected and tested to meet rigorous standards. These methods result in tighter tolerances and better surface finishes, which enhance the precision and reliability of EN-GJL-250 castings. Regular sampling and multiple inspections help detect defects early and maintain product consistency.

Note: Effective quality control ensures that every EN-GJL-250 casting meets customer expectations for durability and performance.

Best Practices for EN-GJL-250 Castings

Design Tips

Engineers achieve optimal performance and manufacturability in EN-GJL-250 castings by focusing on several key design principles. The filling system design plays a crucial role in determining the final quality of Grey Iron Casting components. Simulation analysis and production trials help engineers evaluate different filling system configurations. These methods allow teams to predict casting defects and optimize flow patterns before full-scale production. Economic modeling supports decision-making by comparing the cost-effectiveness of various designs.

- Engineers should use simulation tools to analyze filling system performance.

- Production trials validate simulation results and reveal practical challenges.

- Economic modeling helps select designs that balance quality and cost.

A well-designed filling system ensures uniform metal flow, reduces turbulence, and minimizes the risk of defects. This approach leads to castings with a high degree of accuracy and consistent properties.

Tip: Early collaboration between design and production teams improves manufacturability and reduces costly revisions.

Machining

Machining EN-GJL-250 requires careful selection of process parameters to maximize tool life and surface finish quality. Studies show that turning operations using carbide cutting inserts deliver reliable results. Engineers test different cutting speeds, such as 216, 314, and 433 m/min, to identify the optimal setting for each application. Machine learning models based on vibration acceleration signals help predict tool wear and improve process control.

- Select the optimal cutting speed to extend tool life and minimize wear.

- Adjust feed rates to balance productivity and prevent excessive tool wear.

- Ensure effective chip evacuation to avoid recutting and reduce cutting forces.

- Use robust tooling materials, such as carbide, for machining harder grades.

Proper machining practices maintain the integrity of material equivalent grades and support consistent surface quality. Engineers monitor vibration and tool wear to refine machining parameters and achieve repeatable results.

Note: Regular inspection of cutting tools and adjustment of process settings help maintain high-quality finishes and reduce downtime.

Heat Treatment

Heat treatment enhances the mechanical and physical characteristics of EN-GJL-250 castings. Engineers apply controlled heating and cooling cycles to modify the microstructure. This process can increase hardness, improve wear resistance, and relieve internal stresses. Common heat treatment methods include annealing, normalizing, and stress relieving.

| Heat Treatment Method | Purpose | Effect on Properties |

|---|---|---|

| Annealing | Soften material, improve machinability | Reduces hardness, increases ductility |

| Normalizing | Refine grain structure, enhance strength | Improves uniformity, increases toughness |

| Stress Relieving | Remove residual stresses | Prevents distortion, improves stability |

Engineers select the appropriate heat treatment based on the desired EN-GJL-250 material specification and application requirements. Proper heat treatment ensures that castings meet performance standards and extend service life.

Tip: Document all heat treatment parameters to maintain consistency across production batches.

Inspection

Inspection plays a vital role in ensuring the quality and reliability of EN-GJL-250 castings. Engineers and foundry professionals rely on systematic inspection procedures to verify that cast components meet design specifications and industry standards. Inspection helps identify defects, confirm composition, and validate EN-GJL-250 material properties before components enter service.

A comprehensive inspection process for Grey Iron Casting typically includes several stages:

- Visual Inspection: Inspectors examine cast surfaces for cracks, porosity, and surface irregularities. They check for dimensional accuracy and compare the casting against technical drawings.

- Dimensional Measurement: Technicians use calipers, micrometers, and coordinate measuring machines (CMM) to confirm that critical dimensions match design requirements. Accurate measurements ensure proper fit and function in assemblies.

- Non-Destructive Testing (NDT): NDT methods such as ultrasonic testing, magnetic particle inspection, and dye penetrant testing help detect internal and surface defects without damaging the casting. These techniques provide valuable information about the integrity of material equivalent grades.

- Chemical Analysis: Laboratories perform spectroscopic analysis to verify the EN-GJL-250 chemical composition. This step confirms that the casting contains the correct levels of carbon, silicon, manganese, phosphorus, and sulfur. Consistent composition supports predictable properties.

- Mechanical Property Testing: Engineers conduct hardness tests and tensile strength measurements on sample castings. These tests validate that material properties meet the required standards for strength and durability.

| Inspection Method | Purpose | Typical Tools Used |

|---|---|---|

| Visual Inspection | Detect surface defects | Magnifying glass, flashlight |

| Dimensional Measurement | Verify size and shape | Calipers, CMM, micrometers |

| Non-Destructive Testing | Find hidden flaws | Ultrasonic, magnetic particle |

| Chemical Analysis | Confirm composition | Spectrometer, chemical reagents |

| Mechanical Testing | Assess strength and hardness | Hardness tester, tensile machine |

Tip: Regular inspection throughout the casting process helps prevent costly failures and ensures consistent quality in EN-GJL-250 castings.

Engineers recommend documenting all inspection results and maintaining traceability for each batch. This practice supports continuous improvement and helps resolve customer concerns quickly. Inspection teams should receive training on the latest techniques and standards for Grey Iron Casting. They must understand how material equivalent grades and composition affect casting performance.

Effective inspection guarantees that EN-GJL-250 castings deliver reliable service in demanding applications. By following best practices, manufacturers can uphold high standards and meet the expectations of customers across automotive, machinery, and construction industries.

Common Issues in EN-GJL-250 Castings

Defects

EN-GJL-250 castings often encounter several common defects during production. These issues can affect the performance and reliability of Grey Iron Casting components. Engineers must understand the root causes to prevent costly failures and maintain consistent material properties.

The table below summarizes the most frequent defects found in EN-GJL-250 castings, along with their descriptions, causes, and prevention strategies:

| Casting Defect | Description | Root Causes | Prevention Strategies |

|---|---|---|---|

| Hot Tears | Fractures that form as the casting cools and contracts. | Poorly designed gating systems, alloy impurities, uneven cooling rates. | Ensure uniform cooling, optimize gating systems, use high-purity alloys. |

| Cold Shuts | Lines or gaps formed when molten metal fails to fuse properly. | Poor pouring technique, improper gating design, incorrect pouring temperatures, metal contamination. | Optimize pouring practices, design gating systems for uniform filling, maintain precise temperature control. |

| Slag Inclusions | Non-metallic particles trapped in the metal during casting. | High pouring temperatures, inadequate refining, poor mold design, turbulence in the gating system. | Control pouring conditions, design molds with proper ventilation, use high-quality materials. |

Hot tears often result from uneven cooling or impurities in the composition. Cold shuts occur when molten metal does not fuse correctly, usually due to poor pouring technique or gating design. Slag inclusions appear when non-metallic particles become trapped, which can compromise EN-GJL-250 material properties and reduce component strength.

Tip: Regular inspection and process monitoring help identify defects early and support corrective actions.

Troubleshooting

Engineers and foundry professionals use systematic troubleshooting methods to address defects in EN-GJL-250 castings. They analyze process parameters, review EN-GJL-250 chemical composition, and evaluate mold designs to pinpoint the source of problems.

A typical troubleshooting approach includes:

- Visual Inspection: Teams examine cast surfaces for signs of hot tears, cold shuts, or slag inclusions. They compare findings with design specifications and previous production records.

- Process Review: Technicians assess pouring temperatures, gating system layouts, and cooling rates. They adjust these variables to improve metal flow and reduce defect formation.

- Material Analysis: Laboratories test the EN-GJL-250 material for purity and composition. They recommend changes to alloy content or refining practices if impurities are detected.

- Simulation and Modeling: Engineers use casting simulation software to predict defect locations and optimize mold designs. These tools help visualize metal flow and cooling patterns.

- Preventive Maintenance: Foundries schedule regular equipment checks and sand quality assessments. Consistent maintenance reduces the risk of process-related defects.

🛠️ Note: Effective troubleshooting relies on teamwork and clear communication between design, production, and quality control departments.

By following these steps, manufacturers can minimize defects and maintain the desired EN-GJL-250 material properties in Grey Iron Casting applications. Continuous improvement and attention to detail ensure reliable performance and customer satisfaction.

Conclusion

EN-GJL-250 stands out in Grey Iron Casting for its balanced composition and reliable performance characteristics. Engineers achieve better results by following best practices and selecting the right EN-GJL-250 material equivalent for their applications. Understanding the EN-GJL-250 chemical composition, EN-GJL-250 material properties, and EN-GJL-250 material specification ensures strong, durable castings that meet industry standards. Careful process control throughout design, manufacturing, and inspection stages guarantees consistent quality.

For those seeking a trusted partner in EN-GJL-250 cast iron casting, SHENGRONG delivers quality solutions. 🏭

FAQ

What is EN-GJL-250 in Grey Iron Casting?

EN-GJL-250 is a grade of grey cast iron defined by the EN 1561 standard. It features lamellar graphite microstructure, offering balanced strength, machinability, and vibration damping for industrial castings.

How does EN-GJL-250 chemical composition affect casting performance?

The EN-GJL-250 chemical composition, especially carbon and silicon levels, determines graphite formation and matrix structure. These elements influence material properties such as hardness, wear resistance, and machinability in Grey Iron Casting.

What are common EN-GJL-250 material equivalents?

Common EN-GJL-250 material equivalent grades include GG25 (DIN 1691), ASTM A48 Class 40, and FGL250 (UNE). Engineers select equivalents based on regional standards to ensure consistent mechanical and physical properties.

Which industries use EN-GJL-250 castings?

Automotive, machinery, construction, and energy sectors use EN-GJL-250 cast iron castings. Typical components include engine blocks, pump housings, valve bodies, and machine bases due to reliable material properties.

What are the main advantages of EN-GJL-250 in Grey Iron Casting?

EN-GJL-250 offers cost-effectiveness, excellent machinability, high thermal conductivity, and superior vibration damping. These benefits make it suitable for large-scale production and components requiring stable performance.

How can manufacturers improve corrosion resistance in EN-GJL-250 castings?

Manufacturers apply protective coatings or surface treatments to enhance corrosion resistance. These methods reduce oxidation and extend the service life of EN-GJL-250 cast iron castings in harsh environments.

What defects commonly occur in EN-GJL-250 castings?

Common defects include hot tears, cold shuts, and slag inclusions. Engineers prevent these issues by optimizing gating systems, controlling cooling rates, and maintaining high-quality composition according to EN-GJL-250 material specification.

How do engineers inspect EN-GJL-250 castings for quality?

Engineers use visual inspection, dimensional measurement, non-destructive testing, and chemical analysis. These methods verify EN-GJL-250 material properties and ensure castings meet industry standards and performance requirements.