EN-GJS-500-7 represents a versatile ductile iron material that delivers reliable performance across demanding industrial applications. Understanding EN-GJS-500-7 chemical composition, EN-GJS-500-7 material equivalent grades, and EN-GJS-500-7 mechanical properties enables engineers to optimize component design and manufacturing processes. This comprehensive guide explores the EN-GJS-500-7 material specification, composition details, and practical applications that make it an excellent choice for automotive components, construction equipment, and general engineering applications.

Industry professionals value EN-GJS-500-7 material for several compelling reasons:

- Minimum tensile strength of 500 MPa provides substantial load-bearing capacity for medium to high-stress applications

- Excellent ductility with 7% minimum elongation absorbs impact loads and prevents brittle failure

- Superior machinability compared to steel reduces manufacturing costs and enables efficient production

- Good wear resistance in dynamic applications extends component service life

- Proven reliability across diverse industries including automotive, agricultural machinery, and power generation

- Cost-effective casting process delivers near-net-shape components minimizing material waste

Engineers who understand the EN-GJS-500-7 composition, material properties, and EN-GJS-500-7 material equivalent grades can select appropriate specifications and achieve optimal manufacturing economy while ensuring component reliability.

Key Takeaways

- EN-GJS-500-7 delivers minimum 500 MPa tensile strength with 7% elongation suitable for medium-duty structural applications

- The EN-GJS-500-7 chemical composition includes 2.7-3.7% carbon and controlled silicon for optimal nodular graphite formation

- International EN-GJS-500-7 material equivalent grades include QT500-7 (China), FCD500 (Japan), and ASTM A536 Grade 70-50-05 (USA)

- EN-GJS-500-7 mechanical properties include 320 MPa minimum yield strength with 170-230 HB hardness

- The ferritic-pearlitic matrix with spheroidal graphite provides excellent ductility and fatigue resistance

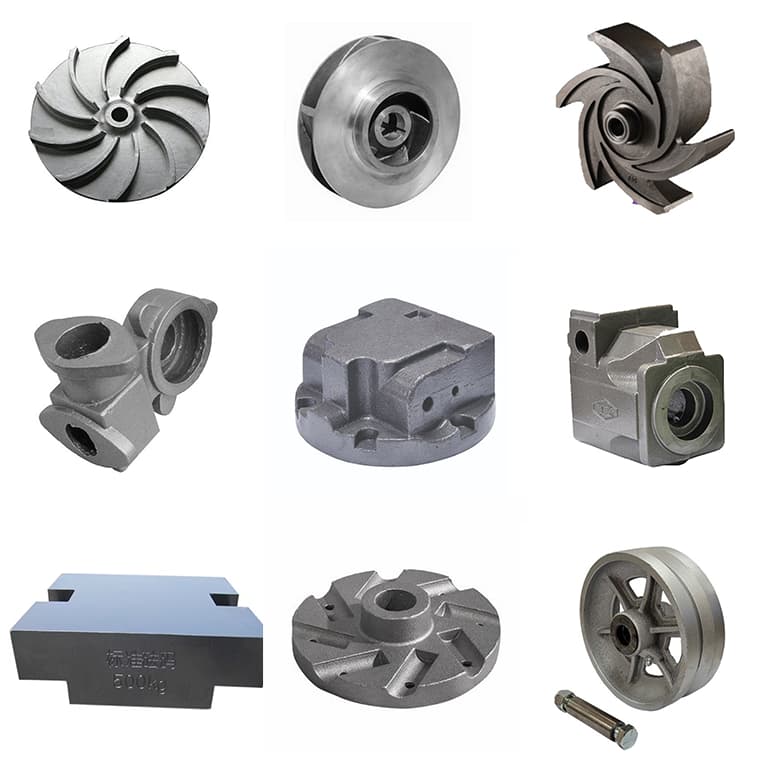

- Applications include brake components, suspension parts, gearbox housings, pump bodies, and agricultural machinery

- Professional ductile iron casting foundries with ISO certification ensure consistent EN-GJS-500-7 material properties

- The EN-GJS-500-7 material specification follows EN 1563 standard requirements for production and testing

What Is EN-GJS-500-7 Material?

Material Classification

EN-GJS-500-7 follows the European standard designation system established by EN 1563 for ductile iron materials. The nomenclature breaks down into specific technical indicators defining material characteristics. “EN” signifies European Norm standardization, ensuring consistent EN-GJS-500-7 material specification across manufacturing regions. “GJS” identifies the material as ductile iron with spheroidal (nodular) graphite structure, distinguishing it from gray cast iron which uses “GJL” designation. The number “500” indicates minimum tensile strength of 500 megapascals measured on standard test bars, while “7” represents minimum elongation percentage.

This standardized designation system helps engineers and procurement specialists quickly identify EN-GJS-500-7 material properties without consulting detailed specification documents. The naming convention eliminates confusion when sourcing materials internationally. Manufacturers reference the same EN-GJS-500-7 composition and performance characteristics regardless of geographic location or supplier.

The material also carries alternative designations in European standards documentation. These alternative designations appear on material certificates and technical documentation. Understanding multiple designation formats facilitates material verification during procurement and quality control processes.

Note: The spheroidal graphite structure distinguishes EN-GJS-500-7 from gray cast iron (EN-GJL series) where graphite appears in flake form. This microstructural difference fundamentally impacts mechanical properties and application suitability, providing significantly higher strength and ductility.

Microstructure Characteristics

The distinctive performance characteristics of EN-GJS-500-7 material stem from its carefully developed microstructure during solidification. Molten iron containing the appropriate EN-GJS-500-7 chemical composition undergoes nodularization treatment with magnesium, causing graphite to precipitate in spheroidal (nodular) form throughout the metallic matrix. These graphite nodules distribute uniformly, creating superior mechanical properties compared to gray cast iron.

The metallic matrix surrounding graphite nodules consists of a ferritic-pearlitic structure in EN-GJS-500-7 material. The balanced ferrite-pearlite combination provides optimal strength with excellent ductility. This microstructure contributes to the material’s good fatigue resistance and impact strength suitable for dynamic loading applications.

| Microstructure Component | Typical Content | Contribution to Properties |

|---|---|---|

| Spheroidal Graphite | 10-15% by volume | Ductility, machinability, stress distribution |

| Ferrite | 40-60% | Ductility, toughness, machinability |

| Pearlite | 40-60% | Strength, hardness, wear resistance |

| Nodule Count | 100-200 nodules/mm² | Mechanical property uniformity |

The graphite nodules act as stress distribution points rather than stress concentrators, which explains the material’s excellent ductility and toughness. This characteristic provides significant advantages in applications requiring impact resistance and fatigue endurance. The nodules also facilitate chip breaking during machining and provide some self-lubricating properties.

The ferritic-pearlitic matrix delivers mechanical strength approaching medium-carbon steels while maintaining excellent casting characteristics and superior machinability. This combination makes EN-GJS-500-7 material properties particularly valuable for applications requiring strength, ductility, and manufacturing efficiency.

Key Performance Attributes

EN-GJS-500-7 excels in applications where its unique combination of properties provides optimal performance. The material demonstrates good wear resistance due to its pearlitic content and adequate hardness. Components manufactured from EN-GJS-500-7 material withstand dynamic loading and surface contact better than gray cast iron while offering better machinability than steel.

Impact resistance represents a distinctive advantage of ductile iron materials. The EN-GJS-500-7 mechanical properties include significant energy absorption capacity through plastic deformation before fracture. Spheroidal graphite nodules prevent crack propagation through the matrix. This inherent characteristic protects components from shock loading, reduces failure risk from accidental overload, and improves safety in critical applications.

Machinability of EN-GJS-500-7 material surpasses steel while providing much higher strength than gray cast iron. The combination of ferritic-pearlitic matrix and spheroidal graphite creates favorable cutting characteristics. Manufacturing operations achieve good productivity when machining ductile iron components with reasonable tool life and good surface finish.

Tip: When designing components requiring combination of strength, ductility, and manufacturing efficiency, consider EN-GJS-500-7 to balance structural performance with production economy through excellent castability and machinability.

EN-GJS-500-7 Chemical Composition

Understanding EN-GJS-500-7 chemical composition provides critical insight into material behavior during casting and service performance. The EN-GJS-500-7 composition includes carefully balanced elements that control graphite nodularization, matrix structure, and mechanical properties. Each element in the EN-GJS-500-7 chemical composition serves specific purposes in achieving desired casting characteristics and performance outcomes.

Primary Alloying Elements

Carbon (C): 2.7% to 3.7%

Carbon content directly determines graphite quantity and nodule formation throughout the EN-GJS-500-7 material. The relatively high carbon concentration enables excellent casting fluidity, allowing complex geometries to fill completely during pouring. During solidification following magnesium treatment, carbon precipitates as spheroidal graphite nodules when proper inoculation and cooling conditions exist.

The EN-GJS-500-7 chemical composition specifies carbon content that balances casting fluidity, nodule formation, and final mechanical properties. The carbon equivalent (CE = %C + %Si/3 + %P/3) typically ranges from 4.3 to 4.6 for optimal EN-GJS-500-7 material properties. This range provides good fluidity while ensuring adequate matrix material for strength development.

Foundries monitor carbon content closely during melting operations. Spectrographic analysis verifies carbon levels before nodularizing treatment of each heat. Proper carbon content combined with effective nodularization treatment ensures spheroidal graphite formation rather than flake graphite or carbides.

Silicon (Si): 0.8% to 2.9%

Silicon acts as a primary graphitizing element and ferrite promoter in ductile iron production. The silicon content within the EN-GJS-500-7 composition range promotes spheroidal graphite formation and influences matrix microstructure. Silicon increases ferrite content in the matrix, enhancing ductility and machinability while moderately reducing strength.

The silicon range in EN-GJS-500-7 chemical composition balances ferrite formation benefits against potential property variations. Higher silicon content increases ferrite percentage, improving ductility and elongation. Lower silicon content promotes pearlite formation, increasing strength and hardness. Foundries optimize silicon content based on desired ferritic-pearlitic balance and component section thickness.

Silicon measurement requires accurate spectroscopic analysis during production. The combined effect of carbon and silicon determines graphite formation tendency and final EN-GJS-500-7 mechanical properties. Foundries use carbon equivalent calculations and specialized software to predict microstructure and property outcomes.

Manganese (Mn): 0.3% to 0.7%

Manganese contributes to pearlite formation in the matrix structure of EN-GJS-500-7 material. This element promotes pearlitic rather than ferritic solidification, increasing strength and hardness while maintaining adequate ductility. The controlled manganese addition in EN-GJS-500-7 composition strengthens the matrix without excessive hardening that would impair machinability or ductility.

Manganese also neutralizes sulfur by forming manganese sulfide inclusions, protecting magnesium from sulfur interference during nodularization treatment. The manganese to sulfur ratio must remain adequate (typically minimum 3:1) to ensure effective nodularization.

Excessive manganese can reduce ductility and increase carbide formation tendency. The specified range provides optimal pearlite development while maintaining good casting characteristics, ductility, and machinability required for EN-GJS-500-7 applications.

Impurity Elements

Sulfur (S): ≤0.02% (maximum)

Sulfur content in EN-GJS-500-7 chemical composition requires strict control during production. Sulfur strongly interferes with magnesium nodularizing treatment by forming magnesium sulfide compounds before graphite nodularization can occur. High sulfur content prevents effective nodularization regardless of magnesium addition quantity.

The EN-GJS-500-7 composition allows maximum 0.02% sulfur, significantly lower than gray cast iron specifications. Foundries select raw materials including pig iron, steel scrap, and foundry returns based on low sulfur content. Ladle desulfurization treatments reduce sulfur to acceptable levels when necessary.

Maintaining low sulfur content ensures effective nodularization treatment and consistent EN-GJS-500-7 mechanical properties. Sulfur control represents one of the most critical aspects of ductile iron production quality management.

Phosphorus (P): ≤0.08% (maximum)

Phosphorus creates brittleness in ductile iron by forming hard, brittle iron-iron phosphide eutectic called steadite. These compounds concentrate at cell boundaries and between dendrites, potentially reducing ductility and impact resistance. The phosphorus limit in EN-GJS-500-7 composition prevents excessive steadite formation.

However, phosphorus moderately improves casting fluidity, helping fill thin sections. The specified range balances improved castability against potential ductility reduction. Components with thin sections may tolerate phosphorus toward the higher end of the range, while impact-loaded applications should minimize phosphorus content.

Raw material selection focuses on controlling phosphorus input. Foundries blend charge materials to achieve target phosphorus levels within EN-GJS-500-7 chemical composition specifications while maintaining production economy.

Nodularizing and Inoculation Elements

Magnesium (Mg): 0.03% to 0.06% residual

Magnesium treatment transforms flake graphite into spheroidal nodules, creating ductile iron’s characteristic microstructure. Foundries add magnesium compounds (typically ferrosilicon-magnesium alloys) to molten iron before casting. The violent reaction requires specialized ladles and safety procedures.

Residual magnesium content after treatment and fading indicates effective nodularization. The EN-GJS-500-7 material specification requires sufficient residual magnesium ensuring spheroidal graphite formation throughout castings. Typical residual magnesium ranges from 0.03% to 0.06% measured in final castings.

Magnesium additions must account for:

- Sulfur neutralization requirements

- Magnesium recovery (typically 40-60% of addition amount)

- Magnesium fading over time before pouring

- Section thickness effects on nodularization

Rare Earth Elements (Ce, La): trace amounts

Modern nodularizing alloys often contain cerium, lanthanum, or other rare earth elements improving nodularization effectiveness and reducing carbide formation tendency. These elements help neutralize carbide-forming elements and improve graphite nodule morphology.

Rare earth additions typically remain below 0.05% to avoid embrittlement. The elements appear in commercial nodularizing alloys combined with magnesium and ferrosilicon.

EN-GJS-500-7 Composition Comparison

Comparing EN-GJS-500-7 chemical composition with adjacent ductile iron grades clarifies the material’s position within the ductile iron family:

| Element | EN-GJS-400-18 | EN-GJS-500-7 | EN-GJS-600-3 |

|---|---|---|---|

| Carbon (C) | 3.2-3.8% | 2.7-3.7% | 3.0-3.6% |

| Silicon (Si) | 1.8-2.8% | 0.8-2.9% | 1.9-2.9% |

| Manganese (Mn) | ≤0.3% | 0.3-0.7% | 0.4-0.8% |

| Phosphorus (P) | ≤0.08% | ≤0.08% | ≤0.08% |

| Sulfur (S) | ≤0.02% | ≤0.02% | ≤0.02% |

Higher-strength grades show progressively higher manganese content and optimized silicon ranges, creating more pearlitic matrices. The EN-GJS-500-7 composition represents a balance between ductility and strength suitable for general engineering applications requiring moderate loading capacity with good impact resistance.

Note: EN 1563 standard specifies that EN-GJS-500-7 chemical composition serves as production guidance rather than acceptance criteria. Final acceptance depends on meeting mechanical property requirements regardless of precise composition values. Foundries optimize composition based on experience and section thickness requirements.

EN-GJS-500-7 Mechanical Properties

The performance characteristics defined by EN-GJS-500-7 mechanical properties determine material suitability for specific engineering applications. Comprehensive understanding of EN-GJS-500-7 material properties enables accurate stress analysis and appropriate safety factors during component design. The EN-GJS-500-7 material specification establishes minimum values ensuring reliable performance across diverse applications.

Tensile Properties

Tensile Strength (Rm): 500-700 MPa (minimum 500 MPa)

Tensile strength represents the primary acceptance criterion for EN-GJS-500-7 material specification. The minimum value of 500 MPa must be achieved when testing separately cast test bars. Typical production material often exceeds the minimum value, with 520-600 MPa common for well-controlled foundry processes.

The tensile strength of ductile iron depends primarily on matrix microstructure and graphite nodule characteristics. Pearlitic matrices provide higher strength than ferritic structures. Optimal nodule count (100-200 nodules/mm²) and uniform nodule distribution improve tensile properties. The EN-GJS-500-7 chemical composition and cooling rate during solidification control these microstructural features.

Testing procedures follow EN 1563 or ISO 1083 standards. Test specimens are machined from separately cast test bars to ensure consistent testing conditions. The test bar cooling rate approximates typical casting sections, providing representative EN-GJS-500-7 mechanical properties.

Yield Strength (Rp0.2): Minimum 320 MPa

Yield strength indicates the stress level where permanent deformation begins, critical for design calculations. The EN-GJS-500-7 material specification requires minimum 320 MPa yield strength, providing adequate safety margin for moderate loading applications.

The yield strength results from matrix composition and heat treatment condition. Ferritic-pearlitic matrices typical of EN-GJS-500-7 provide balanced yield strength with good ductility. Designers use yield strength for allowable stress calculations applying appropriate safety factors.

Elongation (A): Minimum 7%

Elongation percentage indicates ductility, allowing the material to absorb energy and deform before failure. The EN-GJS-500-7 material specification requires minimum 7% elongation, significantly higher than gray cast iron (typically <1%) and approaching some steel grades.

This ductility makes EN-GJS-500-7 suitable for impact-loaded components and applications requiring energy absorption. The spheroidal graphite nodules enable plastic deformation without crack initiation, providing toughness unavailable in gray cast iron.

| Property | EN-GJS-500-7 Value | Test Method |

|---|---|---|

| Tensile Strength (Rm) | ≥500 MPa (typical 520-600 MPa) | EN 1563, ISO 1083 |

| Yield Strength (Rp0.2) | ≥320 MPa | EN 1563, ISO 1083 |

| Elongation (A) | ≥7% | EN 1563, ISO 1083 |

| Brinell Hardness (HB) | 170-230 HB | EN 1563 |

| Impact Energy | 12-20 J (typical, unnotched) | ISO 148 |

Hardness Characteristics

Brinell Hardness: 170-230 HB

Hardness measurements provide rapid, non-destructive verification of EN-GJS-500-7 material properties. The Brinell hardness range correlates with ferritic-pearlitic matrix microstructure typical of this grade. Lower hardness values indicate higher ferrite content providing superior ductility and machinability. Higher values suggest increased pearlite content offering better strength and wear resistance.

Foundries use hardness testing for production quality control. Measurements on production castings or test pieces verify that material meets expected values for the microstructure and EN-GJS-500-7 mechanical properties. Hardness testing requires less time and specimen preparation than tensile testing, making it practical for routine verification.

The hardness range provides good wear resistance in dynamic applications while maintaining excellent machinability. Components operating in moderate wear environments benefit from hardness values toward the upper end of the specification range.

Vickers Hardness: 180-270 HV (equivalent)

Vickers hardness measurements convert approximately to the Brinell hardness range. Vickers testing uses smaller indentation loads suitable for testing finished surfaces or thin-section components where Brinell testing would damage parts. The hardness equivalence enables comparison between testing methods.

Physical Properties

Density: 7.1-7.2 g/cm³

The density of EN-GJS-500-7 material remains relatively constant regardless of composition variations within specification limits. This consistent density simplifies weight calculations during component design. The density closely approximates carbon steel (7.85 g/cm³), making EN-GJS-500-7 slightly lighter for equivalent volumes.

Weight predictions use the standard density value multiplied by component volume. Accurate density enables precise calculation of component mass for shipping, handling, dynamic load analysis, and rotating component balance calculations.

Modulus of Elasticity: 165-175 GPa

The elastic modulus of EN-GJS-500-7 material properties approaches steel values (200-210 GPa) providing good structural stiffness. The spheroidal graphite nodules have less impact on modulus compared to flake graphite in gray iron. Typical values around 169 GPa represent average material behavior under tensile loading.

Engineers must account for the slightly lower modulus compared to steel when calculating deflection under load. However, the difference remains moderate, and ductile iron components provide adequate stiffness for most structural applications. The predictable elastic behavior enables reliable finite element analysis and structural calculations.

Poisson’s Ratio: 0.26-0.29

Poisson’s ratio for EN-GJS-500-7 material closely matches steel values (0.27-0.30). This property affects stress calculations in multiaxial loading conditions and influences lateral strain during tensile loading. The similarity to steel enables standard calculation methods without special modification.

Thermal Properties

Thermal Conductivity: 29-33 W/(m·K)

EN-GJS-500-7 material conducts heat moderately well, though less effectively than gray cast iron (46-50 W/(m·K)) due to the more continuous metallic matrix. The spheroidal graphite nodules provide less thermal pathway than interconnected flake graphite. However, thermal conductivity remains adequate for most engineering applications.

Effective heat conduction supports applications requiring moderate heat dissipation. Components subjected to thermal cycling benefit from adequate conductivity distributing heat more uniformly, reducing thermal stresses and distortion.

Coefficient of Thermal Expansion: 10.5-12.0 × 10⁻⁶/K

The thermal expansion coefficient of EN-GJS-500-7 mechanical properties matches carbon steel values closely. This compatibility minimizes thermal stress when assembling ductile iron components with steel parts. Similar expansion rates prevent loosening or binding across temperature variations.

The spheroidal graphite structure provides good dimensional stability under thermal cycling. Machine components and precision applications utilize this characteristic for maintaining accuracy across temperature ranges encountered in service.

Specific Heat Capacity: 460-500 J/(kg·K)

Specific heat capacity indicates the energy required to change material temperature. EN-GJS-500-7 material absorbs heat similarly to steel. This property influences thermal cycling behavior and temperature change rates during service or heat treatment operations.

Fatigue and Impact Properties

Fatigue Strength

EN-GJS-500-7 demonstrates good fatigue resistance suitable for cyclic loading applications. The spheroidal graphite nodules distribute stress without creating severe stress concentrations. Fatigue strength typically reaches 40-50% of tensile strength at 10⁷ cycles for unnotched specimens.

Surface finish significantly affects fatigue performance. Machined surfaces demonstrate superior fatigue resistance compared to as-cast surfaces. Components subject to cyclic loading benefit from machining critical areas and applying appropriate surface treatments.

Impact Energy

The EN-GJS-500-7 mechanical properties include good impact energy absorption compared to gray cast iron. Unnotched Charpy impact values typically range from 12-20 Joules at room temperature. This impact resistance provides safety margin against shock loading and accidental overload conditions.

Impact energy decreases at low temperatures, though less severely than some steel grades. The ferritic-pearlitic microstructure maintains reasonable toughness across normal operating temperature ranges. Critical applications requiring low-temperature service should verify impact properties at minimum expected temperatures.

Tribological Characteristics

Wear Resistance

The combination of ferritic-pearlitic matrix and spheroidal graphite provides good wear resistance in sliding and rolling contact applications. The EN-GJS-500-7 mechanical properties include adequate hardness resisting abrasive wear. Graphite nodules provide some lubricity reducing friction coefficients.

Components like gears, cam followers, and bearing surfaces benefit from ductile iron’s wear characteristics. The material resists surface fatigue and spalling better than gray iron while offering superior machinability compared to through-hardened steel.

Machinability

EN-GJS-500-7 demonstrates excellent machinability compared to steel with equivalent strength. The ferritic-pearlitic matrix machines efficiently using conventional cutting tools. Graphite nodules provide some chip breaking effect improving chip evacuation and reducing cutting forces.

Typical machining parameters for EN-GJS-500-7 material include:

- Cutting speeds: 120-200 m/min for turning and milling operations

- Feed rates: 0.15-0.45 mm/rev depending on operation type

- Depth of cut: 2-6 mm for roughing, 0.5-2 mm for finishing

- Tool materials: Coated carbide inserts for production; uncoated carbide or HSS acceptable for lighter operations

The moderate hardness of EN-GJS-500-7 mechanical properties balances strength requirements with ease of finishing. Drilling, tapping, and threading operations proceed efficiently. Components can be machined to tight tolerances with good surface finish using standard equipment and reasonable tool life.

Tip: When specifying EN-GJS-500-7 for applications requiring both strength and machinability, the material provides excellent balance between mechanical performance and manufacturing efficiency, often outperforming steel alternatives in total production cost.

EN-GJS-500-7 Material Specification Standards

Multiple international standards govern production and testing of this ductile iron grade, ensuring consistency across manufacturing regions. Understanding applicable EN-GJS-500-7 material specification standards facilitates international sourcing and quality verification.

European Standards

EN 1563:2018 (Current Standard)

The European standard EN 1563 titled “Founding – Spheroidal Graphite Cast Irons” provides comprehensive specifications for ductile iron production and testing. This standard replaced earlier national standards including DIN 1693 (Germany), BS 2789 (United Kingdom), and NF A32-201 (France). The EN-GJS-500-7 material specification follows requirements established in EN 1563.

EN 1563 covers:

- Material designation system and grade classifications

- EN-GJS-500-7 chemical composition guidance ranges

- Mechanical property requirements including test methods

- Test bar casting procedures and dimensions

- Nodule evaluation criteria and acceptance standards

- Inspection and certification requirements

- Acceptance criteria and dispute resolution

The standard specifies minimum tensile strength, yield strength, and elongation values for various ductile iron grades determined from separately cast test bars. The EN-GJS-500-7 material properties must meet minimum requirements measured on standard test bars. Hardness ranges and nodule characteristics provide additional verification of microstructure and properties.

International Standards

ISO 1083:2018 – Spheroidal Graphite Cast Irons Classification

The International Organization for Standardization publishes ISO 1083 covering ductile iron classification and properties. This global standard harmonizes with regional standards including EN 1563. The ISO designation for equivalent material uses “ISO 500-7” indicating minimum tensile strength and elongation.

ISO 1083 establishes:

- Material property requirements

- Test methods and specimen preparation

- Designation system conventions

- International grade equivalencies

- Nodule evaluation standards

Manufacturing facilities producing for international markets typically reference both EN 1563 and ISO 1083 specifications. The standards align closely, with minor differences in test procedures or reporting formats. Material produced to EN 1563 specifications generally satisfies ISO 1083 requirements.

Former National Standards

DIN 1693 (Germany) – GGG50

Before European standard harmonization, German foundries produced this material according to DIN 1693 with designation GGG50. The “GGG” abbreviation stands for “Gusseisen mit Kugelgraphit” (cast iron with spheroidal graphite), while “50” indicates minimum tensile strength classification. Many historical German engineering drawings specify GGG50.

The EN-GJS-500-7 material specification replaced DIN 1693 GGG50 with equivalent properties and applications. Legacy documentation may reference the older designation. Material certificates from German foundries often include both designations facilitating international recognition.

Specification Requirements

Mechanical Property Testing

The EN-GJS-500-7 material specification requires tensile testing of separately cast test bars to verify mechanical properties. Standard test bars typically measure 25mm or 30mm diameter depending on casting size and standard requirements. Test specimens are machined to specified gauge dimensions before testing according to EN ISO 6892-1 procedures.

Testing frequency depends on production volume and customer requirements:

- Per-heat testing for critical applications

- Periodic sampling for established production

- First article inspection for new components

- Special testing for qualification programs

Hardness testing provides supplementary verification without destructive testing requirements. Brinell hardness measurements on production castings or test pieces confirm expected microstructure correlating with mechanical properties.

Metallographic Examination

Microstructure evaluation verifies nodule morphology and matrix structure meet EN-GJS-500-7 material specification. Polished and etched samples examined under microscope confirm:

- Spheroidal graphite nodule distribution and count (typically 100-200 nodules/mm²)

- Nodule spheroidicity and form rating (typically 70-90% nodularity minimum)

- Ferritic-pearlitic matrix balance appropriate for grade

- Absence of excessive carbides, inclusions, or steadite

Metallographic examination typically occurs during process qualification and periodic verification. Critical applications may require per-lot microstructure confirmation ensuring consistent quality.

Documentation and Certification

Foundries supply material certificates documenting compliance with EN-GJS-500-7 material specification requirements. Typical certificates include:

- Chemical composition analysis results

- Mechanical property test data (tensile strength, yield strength, elongation)

- Hardness measurements

- Metallographic examination results including nodule count and nodularity

- Heat identification and traceability information

- Compliance statement with applicable standards

Inspection certificates following EN 10204 Type 3.1 or 3.2 formats provide comprehensive quality documentation. These certificates enable customer verification of material properties and specification compliance, supporting quality systems and regulatory requirements.

Tip: When procuring EN-GJS-500-7 material, specify the required certification level (EN 10204 3.1, 3.2, etc.) and any special testing requirements during initial quotation to ensure proper documentation and avoid delivery delays or misunderstandings.

EN-GJS-500-7 Material Equivalent Grades

Engineers frequently need to identify EN-GJS-500-7 material equivalent grades across international standards for global sourcing and material substitution. Understanding equivalent designations ensures material compatibility when specifications reference different standards. The EN-GJS-500-7 material equivalent system facilitates international trade and technical communication.

Chinese Standard Equivalent

QT500-7 (GB/T 1348)

The Chinese national standard GB/T 1348 designates equivalent ductile iron as QT500-7. The “QT” abbreviation represents “Qiu Tie” (spheroidal iron in Chinese), while “500” indicates minimum tensile strength in MPa and “7” represents minimum elongation percentage. Chinese foundries produce QT500-7 extensively for automotive components, machinery castings, and industrial applications.

The QT500-7 chemical composition and mechanical properties align closely with EN-GJS-500-7 material specification:

- Tensile strength minimum: 500 MPa

- Yield strength minimum: 320 MPa

- Elongation minimum: 7%

- Brinell hardness: 170-230 HB

Chinese automotive manufacturers, machinery producers, and construction equipment manufacturers commonly specify QT500-7. The widespread availability and established production processes make this EN-GJS-500-7 material equivalent readily available from Chinese foundries. Material certificates reference both GB/T 1348 and international equivalent designations facilitating global supply chains.

Japanese Standard Equivalent

FCD500 (JIS G 5502)

Japanese Industrial Standard JIS G 5502 classifies equivalent ductile iron as FCD500. The “FCD” designation abbreviates “Ferrous Casting Ductile” while “500” indicates minimum tensile strength in MPa. Japanese automotive industry and machinery manufacturers utilize FCD500 extensively for engine components, transmission parts, and construction machinery.

FCD500 specifications include:

- Tensile strength minimum: 500 MPa

- Yield strength minimum: 320 MPa (0.2% proof stress)

- Elongation minimum: 7%

- Hardness range: 170-230 HB

The Japanese standard includes rigorous quality control requirements typical of Japanese manufacturing. Test procedures follow JIS methods with acceptance criteria ensuring consistent performance. However, mechanical property targets align with EN-GJS-500-7 material equivalent performance enabling international interchangeability.

American Standard Equivalent

ASTM A536 Grade 70-50-05

The American Society for Testing and Materials specifies ductile iron in ASTM A536 standard. Grade 70-50-05 designation indicates minimum tensile strength of 70,000 psi (approximately 480 MPa), minimum yield strength of 50,000 psi (approximately 345 MPa), and minimum elongation of 5%. This represents the closest ASTM equivalent to EN-GJS-500-7 material specification, though slight property differences exist.

ASTM A536 Grade 70-50-05 characteristics:

- Tensile strength minimum: 70 ksi (480 MPa)

- Yield strength minimum: 50 ksi (345 MPa)

- Elongation minimum: 5%

- Hardness typically: 170-230 HB

The ASTM designation system uses different numbering convention but similar acceptance philosophy. Foundries optimize composition and processing to achieve required strength and ductility. This EN-GJS-500-7 material equivalent provides reliable performance in North American applications.

Note: ASTM A536 Grade 70-50-05 has slightly lower elongation requirement (5% vs 7%) compared to EN-GJS-500-7. Engineers should verify elongation requirements when substituting between standards for applications requiring maximum ductility.

Other International Equivalents

Germany: GGG50 (Former DIN 1693)

German standard historically designated this material as GGG50 before adopting European harmonized standards. The designation “GGG” represents “Gusseisen mit Kugelgraphit” (cast iron with spheroidal graphite). German foundries now primarily reference EN 1563 but legacy documentation may include GGG50 designation.

United Kingdom: SNG 500/7 (Former BS 2789)

British Standard BS 2789 classified this material as SNG 500/7 (Spheroidal or Nodular Graphite iron) before adopting European standards. UK foundries now primarily reference EN 1563, though older specifications may cite BS 2789 designations.

France: FGS 500-7 (Former NF A32-201)

French standard NF A32-201 designated this material as FGS 500-7 where “FGS” represents “Fonte à Graphite Sphéroïdal” (spheroidal graphite cast iron). French foundries now reference EN 1563 as the primary standard.

Italy: GS500-7 (UNI Standards)

Italian standard UNI designates equivalent material as GS500-7. The nomenclature follows similar conventions indicating tensile strength and elongation values. Italian foundries supply this grade for domestic machinery and automotive applications.

Russia: VCh50 (GOST 7293)

Russian standard GOST 7293 classifies this material as VCh50 where “VCh” represents high-strength cast iron (Vysokoprochnyi Chugun) and “50” indicates strength classification. Russian manufacturing facilities produce VCh50 for domestic machinery, automotive, and infrastructure applications.

India: SG500/7 (IS 1865)

Indian standard IS 1865 designates equivalent material as SG500/7. The “SG” prefix indicates spheroidal graphite iron. Indian foundries supply this grade for domestic and export markets serving automotive, agricultural, and general engineering sectors.

Equivalent Grade Comparison Table

| Standard | Designation | Tensile Strength | Yield Strength | Elongation | Primary Region |

|---|---|---|---|---|---|

| European (EN 1563) | EN-GJS-500-7 | ≥500 MPa | ≥320 MPa | ≥7% | Europe |

| ISO 1083 | ISO 500-7 | ≥500 MPa | ≥320 MPa | ≥7% | International |

| China (GB/T 1348) | QT500-7 | ≥500 MPa | ≥320 MPa | ≥7% | China |

| Japan (JIS G 5502) | FCD500 | ≥500 MPa | ≥320 MPa | ≥7% | Japan |

| USA (ASTM A536) | Grade 70-50-05 | ≥480 MPa | ≥345 MPa | ≥5% | North America |

| Germany (Former DIN) | GGG50 | ≥500 MPa | ≥320 MPa | ≥7% | Germany (legacy) |

| Russia (GOST 7293) | VCh50 | ≥500 MPa | ≥320 MPa | ≥7% | Russia/CIS |

| India (IS 1865) | SG500/7 | ≥500 MPa | ≥320 MPa | ≥7% | India |

Material Substitution Considerations

When substituting between EN-GJS-500-7 material equivalent grades from different standards, engineers should verify several critical factors:

Mechanical Property Alignment

Compare minimum tensile strength, yield strength, and elongation requirements across standards. Most EN-GJS-500-7 material equivalent grades specify 500 MPa minimum tensile strength with 7% elongation. The ASTM equivalent (Grade 70-50-05) specifies slightly different values requiring verification for critical applications.

The testing methods may differ slightly between standards. EN and ISO use metric units and test procedures per ISO 6892. ASTM uses imperial units and follows ASTM E8 testing methods. Japanese standards specify JIS testing procedures. These testing variations typically produce comparable results within normal material scatter.

Nodule Quality Requirements

Different standards specify varying nodule evaluation criteria. EN 1563 requires nodule count and nodularity assessment. ASTM A536 includes similar requirements with slightly different acceptance criteria. Verify that nodule quality specifications align with application requirements when substituting materials.

Nodule count typically ranges 100-200 nodules/mm² for EN-GJS-500-7. Nodularity (percentage of nodules with spheroidal form) should exceed 80% for optimal mechanical properties. Standards provide evaluation methods and acceptance criteria ensuring adequate microstructure quality.

Section Thickness Effects

All ductile iron standards recognize that mechanical properties vary with casting section thickness. Thicker sections cool more slowly, potentially producing coarser microstructures with somewhat reduced strength and increased ductility. EN-GJS-500-7 material specification bases properties on standard test bars representing typical section sizes.

When substituting materials, verify that section thickness considerations align across standards. Some standards provide property adjustments for different section sizes. Component design should account for actual section thickness effects on EN-GJS-500-7 mechanical properties.

Heat Treatment Compatibility

Verify that any heat treatment specifications remain appropriate when substituting between EN-GJS-500-7 material equivalent grades. Ductile iron response to thermal treatments generally remains consistent across equivalent materials. However, specific heat treatment parameters may require adjustment based on section size and desired final properties.

Common heat treatments for ductile iron include:

- Stress relief annealing (500-600°C)

- Normalizing (880-920°C)

- Austemperingfor ADI production (special processing)

- Surface hardening (induction or flame)

Tip: For international projects, specify both the primary standard designation and recognized EN-GJS-500-7 material equivalent grades to facilitate global sourcing while maintaining quality consistency. Include detailed mechanical property requirements and testing procedures in procurement specifications.

Primary Applications of EN-GJS-500-7

The balanced combination of strength, ductility, and manufacturing efficiency makes EN-GJS-500-7 material suitable for diverse industrial applications. Understanding typical applications helps engineers evaluate material appropriateness for specific component requirements.

Automotive Components

Brake System Components

Automotive brake components utilize EN-GJS-500-7 material for its combination of strength, thermal properties, and impact resistance. Brake calipers, brake carriers, and wheel hubs benefit from the material’s ability to withstand dynamic loading and thermal cycling. The ductility prevents brittle failure under shock loading conditions.

The casting process creates complex geometries with integrated mounting features and fluid passages. EN-GJS-500-7 mechanical properties provide adequate strength for hydraulic pressure containment and mechanical loads. The material’s damping capacity helps reduce brake noise and vibration transmission.

Commercial vehicles, passenger cars, and light trucks commonly employ ductile iron brake components. The material cost-effectiveness combined with reliable performance makes EN-GJS-500-7 standard for moderate to heavy-duty braking applications.

Suspension Components

Suspension control arms, knuckles, and mounting brackets manufactured from EN-GJS-500-7 material combine adequate strength with good fatigue resistance. The components must withstand cyclic loading from road irregularities while maintaining dimensional stability. Ductility provides safety margin against sudden overload from impacts.

The EN-GJS-500-7 composition enables casting complex shapes with optimized weight distribution. Integrated bushing bores, ball joint mountings, and attachment features reduce assembly operations. The material’s strength-to-weight ratio suits suspension applications requiring both structural performance and weight efficiency.

Transmission and Powertrain Components

Gearbox housings, differential cases, and transmission components cast from EN-GJS-500-7 material provide rigid mounting for gears and bearings while incorporating complex internal features. The casting process creates integral mounting bosses, bearing bores, and oil passages economically. The material’s stiffness maintains bearing alignment under load.

The EN-GJS-500-7 mechanical properties provide adequate strength for mounting loads and gear separation forces. Machinability facilitates precision finishing of bearing bores and sealing surfaces. The material’s proven durability makes it suitable for automotive transmission applications.

Construction and Agricultural Equipment

Excavator and Loader Components

Construction equipment including excavators, wheel loaders, and backhoes utilize EN-GJS-500-7 material for structural components. Bucket teeth adapters, wear plates, linkage components, and mounting brackets benefit from the material’s strength and impact resistance. The ductility prevents brittle fracture under shock loading common in construction applications.

The casting process enables production of complex geometries optimizing material placement for load paths. EN-GJS-500-7 composition provides adequate strength for heavy equipment applications while maintaining manufacturing economy. Components withstand harsh operating environments including impact, vibration, and abrasive conditions.

Agricultural Machinery Parts

Tractor components, implement frames, and power transmission parts leverage EN-GJS-500-7 material’s durability and cost-effectiveness. Plow shares, cultivator shanks, and tillage tool mountings require materials withstanding soil abrasion and impact from rocks or obstacles. The material’s combination of strength and toughness provides reliable service life.

Seed drill components, fertilizer spreader parts, and harvesting equipment utilize ductile iron castings for structural integrity. The EN-GJS-500-7 mechanical properties support agricultural equipment loading while the casting process enables economical production of complex geometries.

Crane and Lifting Equipment

Crane wheels, sheaves, and hook blocks manufactured from EN-GJS-500-7 material provide strength for lifting operations. The material must withstand static and dynamic loading while resisting wear from rolling contact or cable contact. Adequate ductility provides safety margin preventing sudden brittle failure.

Industrial cranes, gantry systems, and material handling equipment commonly specify ductile iron components for reliability. The EN-GJS-500-7 composition delivers proven performance in demanding lifting applications where safety remains paramount.

Industrial Machinery

Pump Housings and Valve Bodies

Water pumps, oil pumps, and industrial pump housings utilize EN-GJS-500-7 material for its casting versatility and pressure containment capability. The casting process creates complex internal flow passages optimizing hydraulic efficiency. The material provides adequate strength for moderate to high-pressure applications.

Valve bodies for water, steam, oil, and industrial process applications benefit from ductile iron’s mechanical properties and machinability. The EN-GJS-500-7 mechanical properties support internal pressure while the material resists many process fluids. Complex internal porting and external mounting features integrate into single castings reducing assembly requirements.

Municipal water systems, industrial plants, HVAC systems, and process industries commonly specify ductile iron pumps and valves. The material’s service life often exceeds decades with proper design, installation, and maintenance.

Gearbox and Power Transmission Housings

Industrial gearbox housings cast from EN-GJS-500-7 material provide rigid mounting for gear trains while incorporating bearing supports and sealing surfaces. The material’s stiffness maintains gear alignment critical for efficient power transmission and quiet operation. Adequate strength supports gear separation forces and external mounting loads.

Precision machining of bearing bores maintains alignment tolerances. The EN-GJS-500-7 composition enables excellent surface finishes on sealing surfaces preventing lubricant leakage. Manufacturing economy through integrated casting makes ductile iron competitive for medium to high-production volumes.

Compressor Components

Air compressor components including cylinder blocks, crankcase housings, and valve plates utilize EN-GJS-500-7 material. The components must withstand cyclic pressure loading while maintaining dimensional accuracy. The material’s combination of strength and machinability suits compressor manufacturing requirements.

Industrial air compressor manufacturers specify ductile iron for reliable performance and manufacturing efficiency. The EN-GJS-500-7 mechanical properties provide adequate strength for pressure containment while the casting process enables economical production.

Infrastructure and Municipal Applications

Manhole Covers and Grating

Municipal infrastructure including manhole covers, drainage grates, and utility access covers utilize ductile iron for its load-bearing capacity, durability, and impact resistance. EN-GJS-500-7 material withstands traffic loads while resisting damage from impacts and environmental exposure. The ductility prevents brittle fracture from vehicle impacts.

The casting process creates anti-skid surface patterns, logos, and identification markings directly. The material’s weight provides security against unauthorized removal while remaining manageable for maintenance access. Ductile iron manhole covers demonstrate service life measured in decades with minimal maintenance.

The EN-GJS-500-7 mechanical properties easily exceed requirements for standard and heavy-duty load ratings. Municipal specifications often require ductile iron rather than gray iron for improved impact resistance and safety.

Water Distribution System Components

Water pipe fittings, valve boxes, and hydrant components manufactured from EN-GJS-500-7 material provide structural integrity for water distribution networks. The material must withstand soil loads, traffic loads, and internal water pressure. Adequate corrosion resistance combined with protective coatings enables long service life in buried applications.

Municipal water utilities specify ductile iron for critical infrastructure components requiring reliability and longevity. The EN-GJS-500-7 composition delivers proven performance supporting essential water distribution systems.

Power Generation Equipment

Generator and Motor Components

Generator housings, motor frames, and mounting structures utilize EN-GJS-500-7 material for structural support and vibration damping. The components must maintain dimensional stability while supporting rotating machinery. The material’s damping capacity helps reduce vibration transmission and operational noise.

Power generation facilities including hydroelectric, thermal, and renewable energy systems commonly employ ductile iron structural components. The EN-GJS-500-7 mechanical properties provide reliable long-term performance in demanding power generation environments.

Turbine Components

Hydraulic turbine components including guide vane assemblies, wicket gates, and mounting flanges benefit from EN-GJS-500-7 material’s strength and castability. The components must withstand water pressure and flow forces while maintaining dimensional accuracy. Complex geometries optimize hydraulic performance through precision casting.

Note: Application selection should consider specific operating conditions including temperature extremes, corrosive exposure, loading patterns, impact requirements, and required service life. Consultation with experienced ductile iron casting foundries helps optimize material selection and component design for specific applications.

Manufacturing Quality Considerations

Successful production of EN-GJS-500-7 components requires sophisticated metallurgical control and comprehensive quality assurance. Professional foundries implement systematic procedures ensuring consistent EN-GJS-500-7 material properties across production.

Melting and Process Control

Charge Material Selection

Modern foundries carefully select raw materials including pig iron, steel scrap, and foundry returns to achieve target EN-GJS-500-7 chemical composition. Pig iron provides reliable carbon and silicon content with low sulfur. Steel scrap adjusts composition and reduces costs. Foundry returns from previous production provide consistent quality.

Raw material analysis verifies composition before charging into furnaces. Spectroscopic testing identifies elements requiring control including carbon, silicon, manganese, phosphorus, and sulfur. Proper charge calculations ensure molten metal composition approaches specification ranges before nodularizing treatment.

Low sulfur content remains critical for effective nodularization. Foundries select raw materials maintaining sulfur below 0.02% or implement desulfurization treatments. Sulfur control represents one of the most important aspects of ductile iron production quality.

Electric Induction Melting

Electric induction furnaces provide precise temperature and composition control for EN-GJS-500-7 production. Induction heating eliminates contamination from combustion products and enables rapid melting with minimal oxidation. Furnace sizes range from 500 kg to 20+ tonnes capacity depending on production requirements.

Melting temperatures typically reach 1480-1520°C ensuring complete dissolution and homogenization. Temperature control maintains consistency affecting casting fluidity and nodularizing treatment effectiveness. Modern furnaces incorporate automated temperature monitoring and power control systems.

Composition Adjustment

During melting, foundries adjust composition through controlled additions of alloying elements. Carbon additions using graphite or high-carbon materials increase carbon content. Silicon additions using ferrosilicon modify silicon levels affecting matrix microstructure. Manganese adjustments use ferromanganese alloys to control pearlite formation.

Spectroscopic analysis throughout melting verifies composition approaches target ranges. Final composition verification occurs before nodularizing treatment. The base iron EN-GJS-500-7 chemical composition must fall within appropriate ranges before proceeding to magnesium treatment.

Nodularizing Treatment

Nodularization represents the critical process step creating spheroidal graphite microstructure. Foundries add magnesium-containing alloys (typically ferrosilicon-magnesium) to molten iron using specialized treatment methods:

- Sandwich Method: Magnesium alloy placed in bottom of treatment ladle, covered with base iron poured on top. The violent reaction occurs within the ladle with containment.

- Plunging Method: Magnesium alloy plunged into molten iron bath in specially designed equipment. Better control but requires special equipment.

- Tundish Cover Method: Magnesium alloy placed in covered ladle section where iron streams through during pouring.

Treatment temperatures typically range 1460-1500°C. Adequate superheat ensures fluidity maintained after temperature drop during violent nodularizing reaction. Magnesium addition quantities account for sulfur neutralization and achieve target residual magnesium (0.03-0.06%).

Inoculation Treatment

Inoculation follows nodularizing treatment, introducing nucleating agents promoting uniform graphite nodule precipitation. Ferrosilicon-based inoculants added to ladles or during pouring ensure optimal nodule count and distribution. Proper inoculation prevents carbide formation and optimizes EN-GJS-500-7 mechanical properties.

Inoculation quantities typically range from 0.3% to 0.8% of metal weight. Multiple inoculation stages (post-nodularization ladle inoculation and mold inoculation) optimize nodule count throughout castings. Inoculation effectiveness fades over time, requiring prompt pouring after treatment.

Quality Control Testing

Chemical Analysis

Spectroscopic analysis verifies EN-GJS-500-7 composition after nodularizing treatment before pouring. Modern optical emission spectrometers provide rapid analysis of all major and minor elements within minutes. Results must fall within specification ranges and residual magnesium must meet minimum requirements.

Carbon, silicon, manganese, phosphorus, sulfur, and residual magnesium measurements confirm compliance with EN-GJS-500-7 chemical composition requirements. Trace element analysis identifies any unexpected contaminants. Automated documentation systems record all analysis results for traceability.

Metallographic Examination

Microscopic examination of polished and etched samples confirms microstructure meets EN-GJS-500-7 material specification. Trained metallographers evaluate:

- Graphite nodule count (typically 100-200 nodules/mm² required)

- Nodule spheroidicity and form rating (minimum 80% nodularity typical)

- Nodule size distribution and uniformity

- Matrix structure (ferritic-pearlitic balance appropriate for grade)

- Absence of excessive carbides, inclusions, or steadite

Digital image analysis systems quantify microstructural features objectively. Nodule count measurements verify adequate nodularization treatment. Nodularity percentage confirms proper spheroidal graphite formation. Matrix analysis verifies ferritic-pearlitic balance producing target EN-GJS-500-7 mechanical properties.

Mechanical Testing

Tensile testing of separately cast test bars verifies EN-GJS-500-7 material properties meet minimum strength and ductility requirements. Test bars typically measure 25mm or 30mm diameter cast under controlled conditions representing typical casting sections. Specimens machine to standard gauge dimensions before testing per EN ISO 6892-1.

Universal testing machines determine:

- Tensile strength (minimum 500 MPa required)

- Yield strength / 0.2% proof stress (minimum 320 MPa required)

- Elongation (minimum 7% required)

Hardness testing provides supplementary verification using Brinell or Rockwell methods. Hardness measurements on test pieces or production castings confirm expected values (170-230 HB) correlating with microstructure and tensile properties.

Dimensional Inspection

Coordinate measuring machines (CMM) and traditional inspection tools verify dimensional accuracy of critical features. First article inspections thoroughly document all dimensions before production approval. Statistical process control monitors key dimensions throughout production runs.

Inspection reports document compliance with drawing specifications including tolerances, surface finish requirements, and geometric dimensioning. Non-conforming dimensions receive investigation and corrective action before continuing production.

Certification and Documentation

Material Certificates

Professional foundries provide comprehensive material certificates documenting EN-GJS-500-7 material specification compliance. Certificates typically follow EN 10204 format standards including:

Type 3.1 Inspection Certificate: Foundry provides test results verified by authorized inspection representative independent of manufacturing department. Results include chemical composition, mechanical properties, metallographic data, heat identification, and compliance statement.

Type 3.2 Inspection Certificate: Similar to 3.1 but includes verification by independent inspection agency or authorized purchaser representative. Critical applications or contractual requirements may specify 3.2 certification.

Certificate content includes:

- Heat identification and traceability

- Chemical composition analysis results including residual magnesium

- Tensile test data from test bars (tensile strength, yield strength, elongation)

- Hardness measurements

- Metallographic examination results (nodule count, nodularity, matrix structure)

- Applicable standard references (EN 1563, ISO 1083, etc.)

- Authorized signatures and company verification

Traceability Systems

Complete traceability links finished castings back through production records to raw material sources. Heat numbers stamped on castings or attached metal tags enable correlation with:

- Melting records and composition data

- Nodularizing and inoculation treatment records

- Pouring records and casting identification

- Heat treatment records (when applicable)

- Inspection and test results

- Material certificate documentation

Traceability systems support quality investigations, warranty claims, and regulatory compliance. Database systems maintain electronic records enabling rapid retrieval of historical production data.

Quality Management Systems

Professional ductile iron foundries maintain ISO 9001:2015 certification demonstrating systematic quality management. The quality management system includes:

- Documented procedures for all critical processes including nodularization

- Personnel training and qualification programs

- Calibrated measurement equipment with maintenance records

- Internal audit programs verifying procedure compliance

- Corrective action systems addressing nonconformances

- Continuous improvement initiatives

Advanced foundries pursue additional certifications including:

- ISO 14001 (Environmental Management)

- ISO 45001 (Occupational Health and Safety)

- IATF 16949 (Automotive Quality Management)

These certifications demonstrate comprehensive management systems supporting consistent EN-GJS-500-7 material properties and reliable product quality throughout production.

Tip: When selecting foundry partners, request facility tours observing nodularizing operations, quality control laboratories, and inspection procedures. Direct observation provides confidence in capabilities beyond certificate review alone, particularly regarding critical nodularization process control.

Selecting a Ductile Iron Casting Foundry

Component quality depends significantly on foundry expertise and manufacturing capabilities. Engineers should evaluate multiple factors when selecting partners for EN-GJS-500-7 production.

Technical Capability Assessment

Metallurgical Expertise

Foundries specializing in ductile iron demonstrate deep understanding of EN-GJS-500-7 composition control, nodularization treatment, and microstructure development. They maintain laboratory facilities equipped for chemical analysis including residual magnesium measurement, metallographic examination with image analysis, and comprehensive mechanical testing. Experienced metallurgists oversee melting operations, nodularizing treatment, and troubleshoot quality issues.

The foundry should provide detailed material certifications including chemical composition with residual magnesium, mechanical test results, and nodule evaluation data. Metallurgical support during design optimization helps engineers select appropriate materials and optimize component geometry for manufacturing.

Nodularization Treatment Expertise

Successful ductile iron production depends critically on effective nodularization treatment. Experienced foundries demonstrate:

- Multiple nodularizing treatment methods (sandwich, plunging, tundish)

- Proper magnesium alloy selection and handling procedures

- Treatment temperature control and monitoring

- Residual magnesium verification and control

- Consistent nodule count and spheroidicity achievement

Visit foundries to observe nodularizing operations and safety procedures. Well-equipped facilities include proper ventilation, safety equipment, and treatment area design. Experienced personnel understand magnesium handling hazards and implement appropriate safety measures.

Pattern Making and Tooling

Comprehensive pattern making capabilities enable rapid prototype development and production tooling fabrication. Modern foundries utilize CAD/CAM systems, CNC machining, and 3D printing for pattern production. The ability to recommend design modifications improving castability demonstrates valuable engineering partnership.

Pattern quality directly affects casting accuracy and surface finish. Professional pattern shops maintain dimensional tolerances ensuring consistent casting reproduction. Proper pattern design including draft angles, parting lines, and gating locations optimizes manufacturing efficiency.

Heat Treatment Facilities

On-site heat treatment equipment including stress relief furnaces, normalizing furnaces, and surface hardening systems provides complete manufacturing solutions. Foundries should demonstrate knowledge of appropriate thermal cycles for EN-GJS-500-7 material and ability to verify results through hardness testing and metallographic examination.

Common heat treatments for ductile iron include:

- Stress relief (500-600°C) – reduces residual stresses

- Normalizing (880-920°C) – refines microstructure

- Ferritic annealing (optional) – maximizes ductility

- Surface hardening (induction/flame) – increases wear resistance

Machining Services

Integrated machining capabilities allow delivery of finished components rather than rough castings. CNC machining centers, precision grinding equipment, and coordinate measuring systems support tight-tolerance manufacturing. This integration reduces supplier management complexity and improves delivery coordination.

Machining capabilities should match component complexity and tolerance requirements. The foundry’s quality inspection procedures verify machined dimensions meet specifications. Integrated operations often achieve better cost and delivery performance than separate casting and machining suppliers.

Quality System Verification

ISO Certification Review

Professional foundries maintain ISO 9001:2015 quality management certification at minimum. Review certification scope ensuring it covers ductile iron casting operations including nodularization processes. Request copies of current certificates verifying validity and accreditation body credentials.

Advanced foundries pursue additional certifications relevant to specific industries:

- IATF 16949 for automotive supply

- AS9100 for aerospace applications

- ISO 13485 for medical device components

Certification demonstrates systematic quality management though it doesn’t guarantee specific component quality. Combine certification review with capability assessment and sample evaluation.

Production Sample Evaluation

Request sample castings demonstrating the foundry’s capability to produce components meeting EN-GJS-500-7 material specification. Examine samples for:

- Surface quality and finish

- Dimensional accuracy relative to specifications

- Absence of visible casting defects

- Proper nodule formation through metallographic examination

- Machining quality (if applicable)

Review accompanying material certificates confirming mechanical properties, chemical composition including residual magnesium, and nodule evaluation data. Metallographic examination of sample cross-sections verifies microstructure quality including nodule count, nodularity, and matrix structure.

Process Control Documentation

Request examples of process control documentation including:

- Nodularization treatment procedures and records

- Control plans defining inspection points

- Statistical process control charts for critical parameters

- Corrective action records

- Internal audit results

Well-documented processes indicate mature quality systems. Evidence of continuous improvement activities demonstrates commitment to quality enhancement. Transparent documentation sharing builds confidence in capabilities.

Engineering Support Services

Design Collaboration

The best foundry partners offer collaborative engineering support during component development. They provide design for manufacturing guidance optimizing component geometry for improved castability and EN-GJS-500-7 mechanical properties. Experience-based recommendations prevent common casting defects and reduce manufacturing costs.

Finite element analysis capabilities help predict stress distributions and identify potential failure modes. Solidification modeling optimizes feeding systems preventing shrinkage defects and ensuring adequate mechanical properties. Collaborative engineering approach often yields superior results compared to simply manufacturing submitted designs.

Prototyping Capabilities

Rapid prototyping services enable testing and validation before committing to production tooling. 3D-printed patterns, rapid tooling methods, and small-batch casting support design iterations. Prototype testing validates EN-GJS-500-7 material properties meet application requirements before volume production investment.

Flexible prototype processes accommodate design changes with minimal cost and time impact. Successful prototype validation provides confidence before production tooling expenditure.

Capacity and Delivery Performance

Production Capacity Evaluation

Evaluate foundry production capacity relative to component volume requirements. Adequate capacity prevents delivery delays and maintains quality consistency. Review existing customer commitments and available capacity for new projects.

Foundries should maintain buffer capacity handling unexpected demand variations or schedule changes. Equipment redundancy provides continuity during maintenance or equipment issues. Balanced capacity loading prevents rushed production compromising quality.

Geographic Considerations

Geographic location affects transportation costs and lead times. Regional foundries may provide advantages for prototype development and technical support. However, qualified international foundries can deliver competitive pricing for larger production volumes when schedules permit longer transit times.

For manufacturers seeking a reliable ductile iron casting foundry partner with proven expertise in EN-GJS-500-7 production, SHENGRONG delivers specialized capabilities in ductile iron manufacturing with comprehensive quality assurance. The foundry maintains ISO 9001 certification and operates advanced metallurgical laboratories ensuring consistent EN-GJS-500-7 material properties through rigorous nodularization control and testing protocols. From initial design consultation through final inspection and delivery, SHENGRONG provides complete casting solutions for demanding applications requiring reliable performance and exceptional quality standards.

Design Considerations for EN-GJS-500-7 Components

Proper component design maximizes ductile iron advantages while avoiding common issues compromising performance or increasing costs. Understanding design principles optimizes EN-GJS-500-7 material properties in service applications.

Wall Thickness Design

Uniform Section Thickness

Maintaining reasonably uniform wall thickness throughout components promotes even cooling rates and consistent EN-GJS-500-7 mechanical properties. While ductile iron tolerates section variations better than gray iron, excessive thickness changes create property variations and increase defect risk during solidification.

Design guidelines recommend transition ratios not exceeding 1:2 for thickness changes. Gradual tapers or radiused transitions provide smooth stress flow and improve casting soundness. Relatively uniform sections also improve casting yield and reduce shrinkage defect risk.

Consistent cooling rates produce more uniform microstructure and nodule distribution throughout components. The EN-GJS-500-7 composition solidifies predictably when section thickness remains reasonably consistent, minimizing property variation between different component areas.

Section Thickness Selection

Select wall thickness based on strength requirements and manufacturing constraints. Typical EN-GJS-500-7 applications use sections ranging from 6mm to 80mm thickness. Thinner sections (6-15mm) suit moderately loaded components requiring weight reduction. Medium sections (15-40mm) balance strength with reasonable casting difficulty. Heavier sections (40-80mm) accommodate high loads through increased cross-sectional area.

Avoid unnecessarily thick sections wasting material without improving performance. Ribbing, gussets, and structural optimization provide stiffness more efficiently than simply increasing wall thickness. Finite element analysis helps optimize section sizing for specific loading conditions.

Minimum practical wall thickness depends on casting size and complexity. Small castings may achieve 4-5mm walls while large castings typically require 8-12mm minimum. Consult foundry partners regarding minimum thickness capabilities for specific geometries and pouring methods.

Stress Concentration Management

Fillet Radii

Generous fillet radii at internal corners reduce stress concentrations and improve fatigue life. Minimum fillet radius should equal wall thickness or 6mm, whichever is greater for EN-GJS-500-7 components. Larger radii provide additional benefits without significantly increasing casting difficulty.

Sharp internal corners create stress risers that initiate crack formation under cyclic loading. While EN-GJS-500-7 material provides better ductility than gray iron, stress concentration avoidance remains important for fatigue-loaded applications. Proper filleting distributes loads more uniformly.

External corners benefit from radii as well, improving casting quality by promoting smooth metal flow during mold filling. Radiused corners resist handling damage compared to sharp edges. Standard radii of 3-5mm serve most external corner applications.

Hole and Opening Design

Holes and openings create stress concentrations requiring careful design attention. Position holes away from high-stress regions when possible through structural analysis. Maintain adequate material between holes and component edges preventing thin webs.

Reinforce hole perimeters with thickened sections or raised bosses when loads concentrate at these locations. The reinforcement distributes stress over larger areas reducing peak stress values. Avoid placing holes at section thickness transitions where stress concentrations already exist.

Cast holes rather than drilling when dimensions and tolerances permit, as casting creates favorable material flow around openings. However, precision requirements often necessitate drilling and reaming for accurate dimensions.

Casting Process Considerations

Draft Angles

Provide adequate draft angles (typically 1-3 degrees) on surfaces perpendicular to parting lines. Draft enables pattern removal from sand molds without damage to mold surfaces. Insufficient draft damages molds reducing casting surface quality.

External surfaces typically require 1-2 degrees draft. Internal surfaces and deep pockets need 2-3 degrees or more depending on depth. Consult foundry partners regarding draft requirements for specific geometries and molding processes.

Parting Line Location

Collaborate with foundries selecting optimal parting line locations. Proper placement minimizes machining requirements, reduces casting complexity, and improves surface quality. Parting lines should bisect components at maximum dimensions when possible, simplifying molding operations.

Avoid parting lines intersecting critical machined surfaces or sealing surfaces. The parting line may leave slight mismatch or flash requiring removal. Locating parting lines on non-functional surfaces simplifies finishing operations and preserves critical surface integrity.

Coring Requirements

Complex internal features require cores increasing casting cost and complexity. Design components with internal passages accessible for core placement and removal. Minimize core quantity through thoughtful geometry design balancing functionality with manufacturing efficiency.

Simple through-holes often cast more economically than complex internal cavities. Consider whether machining internal features might cost less than casting them for low to medium-volume production. Discuss coring strategies with foundries during design development to optimize manufacturing approach.

Undercut Avoidance

Undercuts prevent straight pattern removal from molds and should be avoided unless absolutely necessary. When unavoidable, discuss alternative manufacturing approaches including split patterns, loose pieces, or machining undercut features after casting.

Redesigning geometry eliminating undercuts often reduces manufacturing costs significantly. Small design modifications may eliminate expensive special tooling or additional operations without compromising component functionality.

Machining Allowances and Surface Finish

Machining Stock Provision

Provide adequate machining allowance (typically 2-5mm per surface depending on casting size) on features requiring precise dimensions or smooth finish. As-cast surfaces exhibit roughness from sand contact and dimensional variation from casting process tolerances.

Critical mating surfaces, bearing bores, mounting faces, and sealing surfaces require machining to achieve necessary accuracy. The EN-GJS-500-7 material machines efficiently, but adequate stock ensures complete surface cleanup removing any surface defects or dimensional variations.

Minimize total machining requirements to preserve cost advantages of near-net-shape casting. Many surfaces can remain as-cast when precise dimensions or smooth finish aren’t functionally required. The natural as-cast surface provides adequate appearance and corrosion resistance for many applications.

Surface Finish Requirements

Specify surface finish requirements realistically based on functional needs. As-cast surfaces typically achieve 12.5-25 µm Ra (500-1000 µin) depending on molding process and sand type. Machined surfaces readily achieve 1.6-6.3 µm Ra (63-250 µin) with standard tooling and parameters.