Home > Factory casting capacity

2015, Jiangsu Shengrong Established

Factory group iron foundry 200000 Square meter

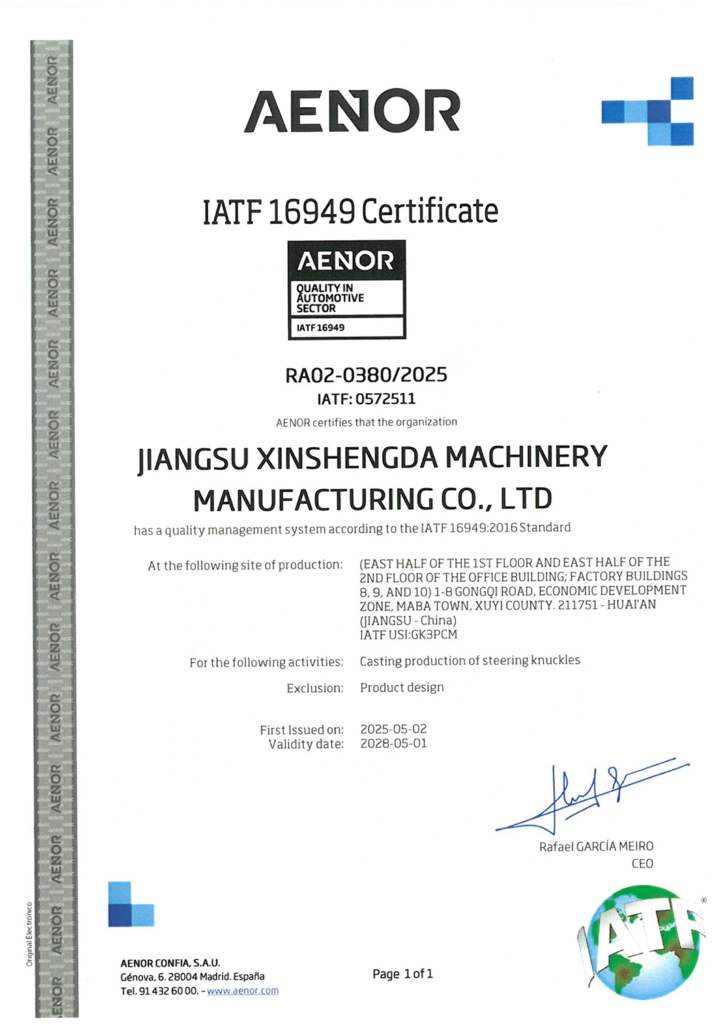

ISO AND IATF16949 Certificate

200+Workers including 25 engineers

More than 100 customers in the world

We are iron and steel casting foundry, with resin sand casting and lost foam casting for ductile iron and gray iron part from 1 kg to 10000 kg parts, we make OEM machinery parts according to your detailed drawing(2D and 3D drawing).

1 set of 1T one-to-two induction medium frequency electric furnace

1 set of 2T one-to-two induction medium frequency electric furnace

melting capacity of 60 tons every day

Sand processing system, single-day molding sand production capacity of 400 tons

30 sets of coated sand core shooting machines

Cooling cleaning machine

Shot blasting machine

Heat treatment machine

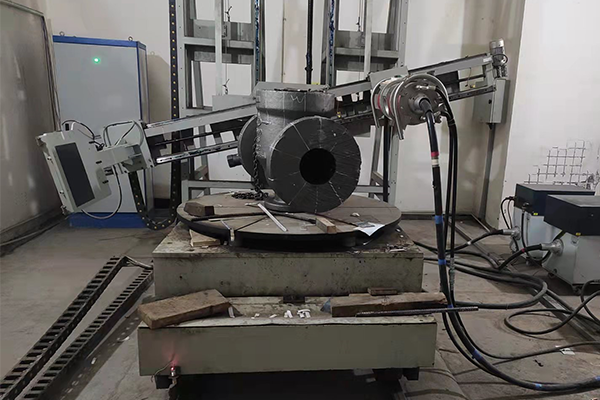

Metallurgical microscope

Tensile tester

Radial inspection machine

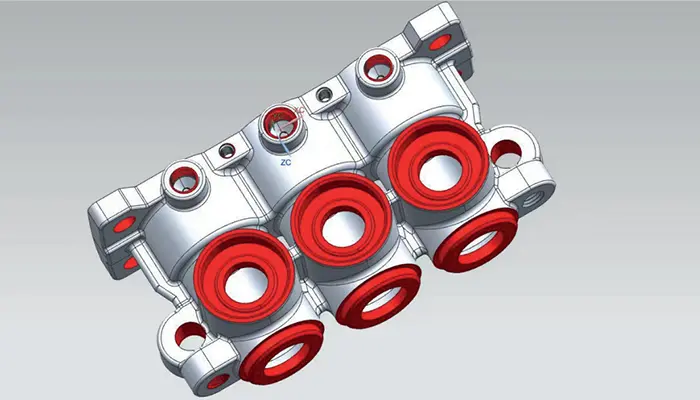

We have 1set 1005 horizontal machining center, 6sets 630 horizontal machining centers, 1set 500 horizontal machining center, 7sets 850 vertical machining centers, 3sets 1160 vertical machining centers, and 1set CMM Main Machining: robot joints, reducer boxes, aluminum alloy high-voltage housings, textile machinery accessories, etc.

1005 horizontal machining center-double station

630 horizontal machining center–6sets

500 horizontal machining center

850 vertical machining center-7sets

We have established an engineering technology materials R&D center to invest more in product development and technological innovation. In line with the CAD and UG three-dimensional mold creation capabilities equipped with independent R&D, we can reduce design defects, improve casting quality, and improve product processing and casting methods, technologies and The improvements and innovations in the process have made Shengrong a complete solution provider in the high-end casting industry that integrates R&D and production.

Casting Inspection

1.Visual Inspections

2.Dimensional Inspections

3.Chemical Inspections

4.Mechanical Properties Inspections

+86 152 9511 6438

+86 152 9511 6438

CONTACT

Get In Touch