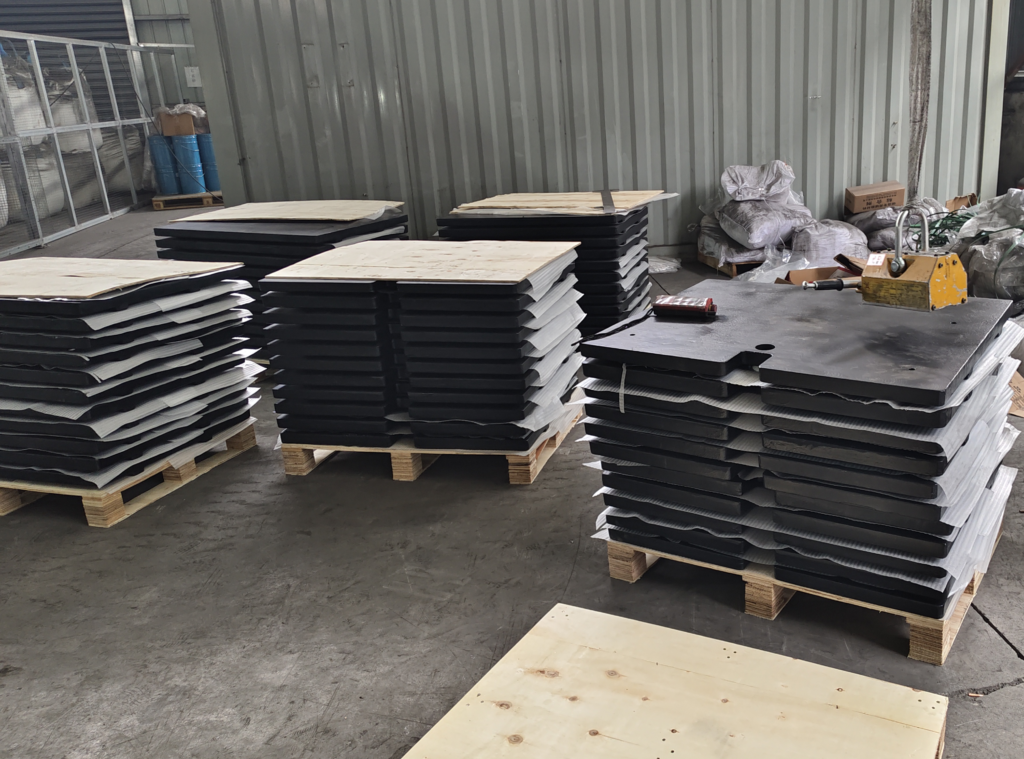

Cast iron Counterweights shipping to USA. Recently, China and the United States reached an agreement on a trade agreement, and the tax rate will remain low for three months. American customers seized this golden time to ask us to ship and added new orders.

The counterweights ordered by American customers is a counterweight block, which is made of gray cast iron and used in cranes. Customers purchase many models, ranging in weight from 120 kg to 580 kg.

The types of counterweight iron include elevator counterweight blocks, marine counterweight blocks, tower crane counterweight blocks, loader counterweight blocks, etc. Counterweight iron process: modeling, core lowering and box closing, pouring, unpacking, shot blasting, cleaning and grinding, puttying, and painting.

Casting standards for counterweight iron blocks:

- Material: It should be made of fine-grained gray cast iron or alloy cast iron, and the material is HT150, HT200, Q235.

- Specifications: The specifications of counterweight iron are generally designed and produced according to the actual production needs of users or according to user requirements.

- Casting defects: Pores and sand holes should not be produced during the casting of the counterweight iron. For sand holes with a diameter less than 15mm, they can be filled with solids of the same material. Note that the hardness of the filler must be lower than the hardness of the counterweight itself.

- Sand cleaning and painting: The counterweight iron should be clean and sprayed with red anti-rust paint.

- Casting method: Full mold casting. In production, polystyrene foam molds are used and furan resin self-hardening sand molding is used. When the molten metal is poured into the mold, the foam plastic mold is quickly vaporized and burned and disappeared under the action of the high-temperature molten metal. The molten metal replaces the position originally occupied by the foam plastic and cools and solidifies into a full-molded casting with the same shape as the mold.

- Hoisting: On the two opposite sides of the counterweight iron, hoisting facilities such as mounting handles and lifting rings should be set. When designing the hoisting position, it should be considered to minimize the changes caused by hoisting.

- Weight deviation: During the production process, the weight deviation of the counterweight iron will occur. The design of the counterweight iron often takes into account the casting error and the machining error. The weight error of the counterweight iron shall not exceed 10%. If it exceeds 10%, the quality of the counterweight iron shall be further identified to determine whether the counterweight iron can be put into use.

Application of counterweight iron:

Light and heavy industrial counterweight iron can be used as accessories on different products in different fields, which fully plays the role of increasing weight and maintaining balance. Counterweight iron is not only used in large mechanical equipment, but also in various industries, such as in engineering machinery, such as excavator counterweight iron, forklift counterweight iron, loader counterweight iron, crane counterweight iron; generally, tractors that pull goods have too heavy goods, and counterweight iron should be placed in the front or rear of the vehicle to increase the friction of the tire and thus increase traction; the fixed telephone handsets we use daily also generally use counterweight iron to increase the hand feel weight, etc. There are also counterweight blocks for elevators;

Counterweight iron is used in small household appliances, toys and other fields. Some of the counterweights in these fields are used to maintain the balance and stability of their own center of gravity, while others are used to compensate for the light weight of the product itself to increase the weight and feel. At the same time, the application of counterweights in these fields is sometimes a reasonable design choice and an economical method of application.

Design standards for counterweight casting:

In the casting process, the design of the counterweight casting process has a great influence on the quality of the cast product, but the selection method of the pouring system cannot be ignored.

The design of the shrinkage compensation system is an engineering technology that reasonably designs the counterweight risers and subsidies to compensate for the liquid and solidified shrinkage of the counterweight castings during the solidification process to obtain a sound casting.

The counterweights produced by our company have the following advantages:

1: Customized according to customer drawings, competitive prices

2: Short delivery time, 30 days under normal circumstances

3: Good surface roughness and very precise weight

4: Small dimensional tolerance range, easy installation by customers

5: Free simple machining and surface painting