Home > Green sand casting

Green sand casting

Green sand casting

Clay sand casting, also known as green sand casting, refers to the process of mixing raw sand, clay (usually bentonite), additives (such as pulverized coal) and water in a certain proportion to make molding sand with good plasticity and strength. The sand is then filled around the mold and, after compaction, the mold is removed to form a hollow casting cavity that is consistent with the shape of the part. Finally, molten metal is poured into the cavity. After it cools and solidifies, the sand mold is broken to obtain the casting.

Manufacturing Process

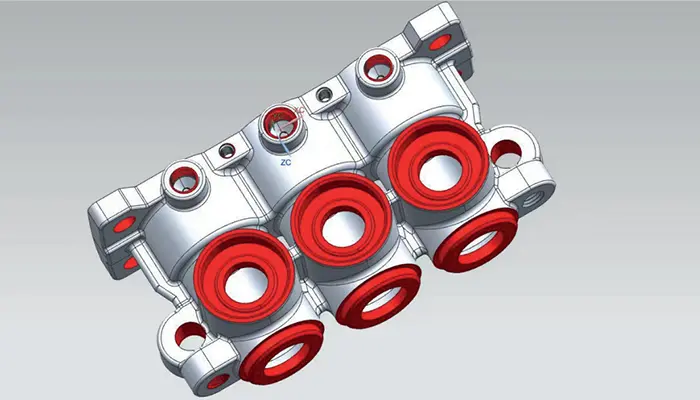

Select the casting process

We select the appropriate casting process according to customer’s 2D and 3D drawing, drawing should show the unit weight, material grade number, size, tolerance and standard and order quantity. Use appropriate casting solidification simulation software and design reasonable casting process to ensure that castings that meet customer quality requirements are obtained.

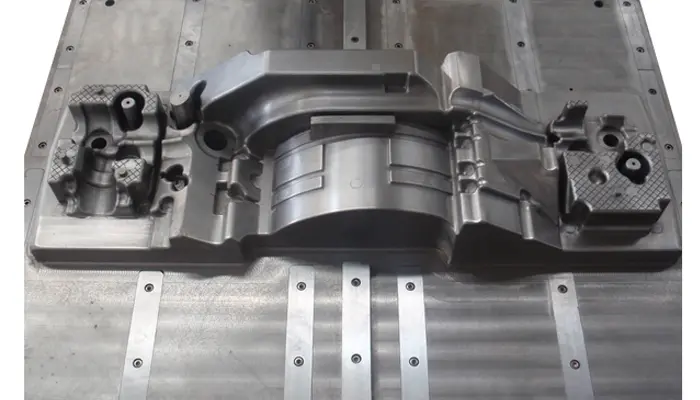

Casting molds design

We select appropriate mold materials and mold making methods according to the specific casting process and casting quality requirements, make the mold according to the designed casting process to ensure the mold quality and dimensional tolerance grade requirements.

Molding and core making

Produce samples according to the selected modeling and core making methods. Produce qualified casting molds and sand cores. Assembly them carefully to ensure that the appearance quality and dimensional tolerance of the castings, so must meet customer requirements.

Melting and pouring

When the customer has clear requirements on the chemical composition of the casting, we will strictly control it according to the customer’s requirements. If the customer has no clear requirements on the chemical composition of the casting, we will determine the chemical composition control range of the molten metal and various production process parameters such as the pouring temperature according to our professional experience to ensure that the casting material meets the customer’s requirements.

Cleaning and inspection

Remove the excess materials such as the gate, riser and seam of the trial sample, and carefully grind and shot blast. Then the trial sample is inspected for appearance quality, size, body hardness and other material properties. If there is a non-destructive testing grade requirement for the internal quality of the casting, the sample is also required to undergo non-destructive testing and body anatomical inspection. Once the sample meets the customer’s quality requirements, it can be transferred to small batch production.

Advantages of green sand casting:

Low Cost: Raw materials (sand and clay) are widely available and inexpensive, and the recycled sand recycling rate is high (over 90%).

Wide Adaptability: Castings ranging from a few kilograms to tens of tons, with extremely complex shapes and various batch sizes can be produced, making it particularly suitable for iron castings.

High Production Efficiency: Easily mechanized and automated production lines (such as molding lines) are available, resulting in short production cycles.

Flexibility: A wide selection of mold materials (wooden and metal) allows for relatively short production cycles.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Green sand casting is a widely used casting process, primarily used in:

Automotive industry: engine blocks, cylinder heads, transmission housings, brake drums, wheel hubs, etc.

Machine tool industry: large castings such as bed frames, guide rails, and housings.

General machinery: various pump casings, valves, and pipe fittings.

Agricultural machinery: tractors and many diesel engine components.