Selecting the right ductile iron casting grade can determine if a project succeeds or fails. Imagine a manufacturer who needs to choose between several ductile iron options for a new pipeline. Each ductile iron grade offers different levels of strength and flexibility. The choice affects how long the product lasts and how much it costs to maintain. Tip: Always match the ductile iron properties to the specific application to maximize performance and durability.

Key Takeaways

- Choosing the right ductile iron casting grade is crucial for project success. It impacts strength, flexibility, and overall performance.

- Ductile iron grades vary in mechanical properties like tensile strength, yield strength, and elongation. Understand these differences to select the best grade for your needs.

- Common grades include ASTM A536 60-40-18, 65-45-12, and 80-55-06. Each grade serves specific applications, from infrastructure to automotive components.

- Always check mechanical properties when comparing grades. This ensures the selected ductile iron meets the demands of its intended use.

- Consider environmental factors like corrosion resistance when selecting a grade. This helps ensure long-lasting performance in harsh conditions.

- Consulting with experts can provide valuable insights into material selection. Their knowledge can help avoid costly mistakes.

- Balancing cost and performance is key. Higher strength grades may cost more upfront but can lead to lower maintenance and replacement costs over time.

- Regular inspection and maintenance of ductile iron components can extend their service life, especially in challenging environments.

Ductile Iron Grades

What Are Ductile Iron Grades

Ductile iron grades define the mechanical properties and composition of ductile iron. Manufacturers use these grades to ensure that castings meet specific requirements for strength, flexibility, and durability. Each ductile iron casting grade represents a unique combination of tensile strength, yield strength, and elongation. These properties determine how ductile iron performs in different environments and applications. Engineers rely on ductile iron grades to select materials that match the demands of their projects. The importance of choosing the correct ductile iron casting grade cannot be overstated. The right grade improves product lifespan, reduces maintenance costs, and enhances safety.

Types of Ductile Iron Grades

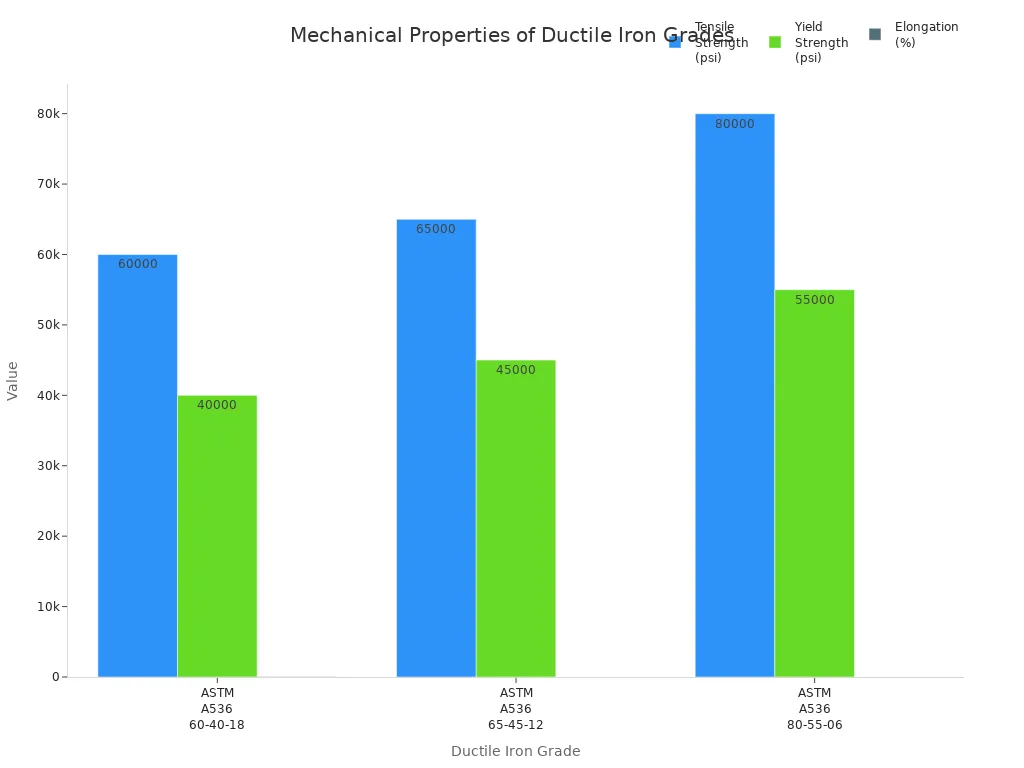

The types of ductile iron grades vary based on mechanical properties and international standards. Common ductile iron grades include ASTM A536 60-40-18, 65-45-12, and 80-55-06. These grades differ in tensile strength, yield strength, and elongation. For example, ASTM A536 60-40-18 offers high elongation and moderate strength, making it suitable for applications requiring flexibility. ASTM A536 80-55-06 provides higher strength but lower elongation, ideal for heavy-duty castings. The selection of ductile iron casting grade depends on the intended use, whether for infrastructure, automotive, or specialty components. Engineers must evaluate the types of ductile iron grades to ensure optimal performance.

| Grade | Tensile Strength (min, psi) | Yield Strength (min, psi) | Elongation (min %) |

|---|---|---|---|

| ASTM A536, GRADE 60-40-18 | 60,000 | 40,000 | 18 |

| ASTM A536, GRADE 65-45-12 | 65,000 | 45,000 | 12 |

| ASTM A536, GRADE 80-55-06 | 80,000 | 55,000 | 6 |

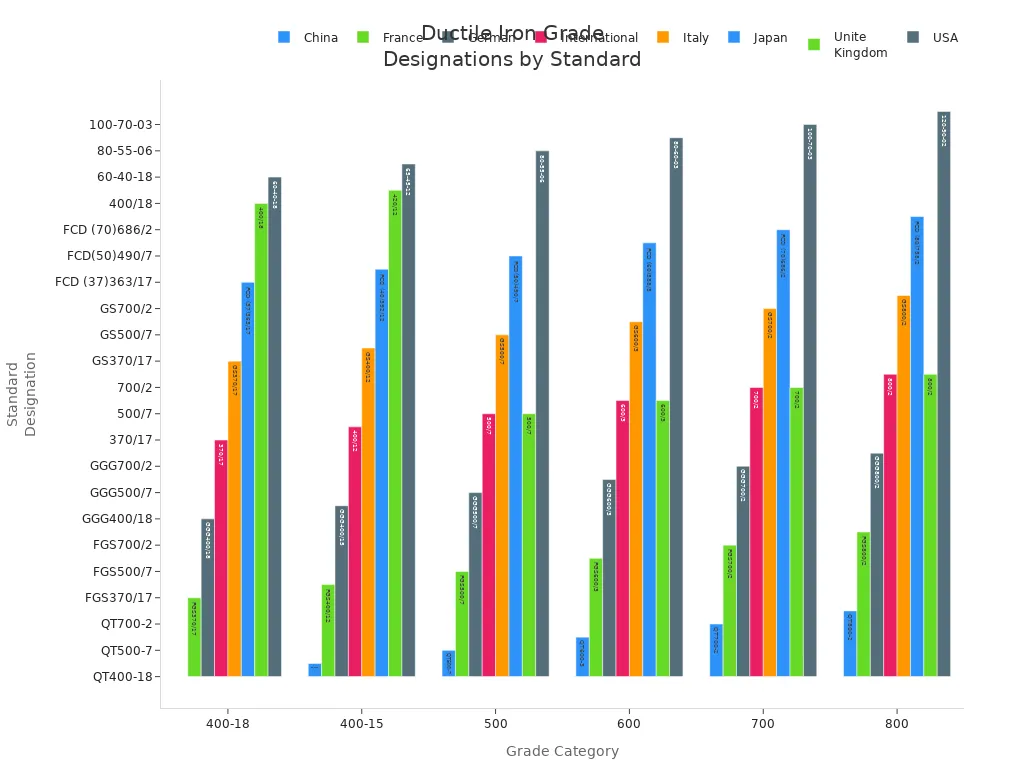

Ductile Iron Casting Grade Standards

International standards classify ductile iron grades to ensure consistency and reliability in global manufacturing. Each country or region uses its own specification system, but many grades are equivalent across standards. For example, ISO 1083, GB/T 1348, ASTM A536, DIN 1693, EN 1563, JIS G5502, UNI 4544, NF A32-201, BS 2789, IS 1865, UNF, NBN, AS, SS, and NS all define ductile iron casting grades with similar mechanical properties. These standards use grade models such as EN-GJS-400-15, QT400-18, FCD400, GGG40, and 60-40-18 to indicate the minimum tensile strength, yield strength, and elongation.

| Country | Specification | 400-18 | 400-15 | 500 | 600 | 700 | 800 |

|---|---|---|---|---|---|---|---|

| China | GB/T 1348-1988 | QT400-18 | QT400-15 | QT500-7 | QT600-3 | QT700-2 | QT800-2 |

| France | NFA 32-201-1976 | FGS370/17 | FGS400/12 | FGS500/7 | FGS600/3 | FGS700/2 | FGS800/2 |

| German | DIN 1693-1973 | GGG400/18 | GGG400/15 | GGG500/7 | GGG600/3 | GGG700/2 | GGG800/2 |

| International | ISO 1083-1976 | 370/17 | 400/12 | 500/7 | 600/3 | 700/2 | 800/2 |

| Italy | UNI 4544-1979 | GS370/17 | GS400/12 | GS500/7 | GS600/3 | GS700/2 | GS800/2 |

| Japan | JIS G5502-1982 | FCD (37)363/17 | FCD (40)392/12 | FCD(50)490/7 | FCD (60)588/3 | FCD (70)686/2 | FCD (80)758/2 |

| United Kingdom | BS2789-1985 | 400/18 | 420/12 | 500/7 | 600/3 | 700/2 | 800/2 |

| USA | ASTM A536-84-1976 | 60-40-18 | 65-45-12 | 80-55-06 | 80-60-03 | 100-70-03 | 120-90-02 |

The world ductile iron grades share similar mechanical properties, but each standard uses its own naming convention. For example, EN-GJS-400-15 in the European standard matches QT400-18 in China and 60-40-18 in the USA. These equivalencies help manufacturers and engineers select the correct ductile iron casting grade for international projects.

Tip: Always check the mechanical properties such as tensile strength, yield strength, and elongation when comparing different grades of ductile iron. These values determine the suitability of ductile iron for specific applications.

Tensile strength measures the maximum stress ductile iron can withstand before breaking. Yield strength indicates the stress at which ductile iron begins to deform permanently. Elongation shows how much ductile iron can stretch before fracturing. The unique properties of ductile irons, such as high strength and flexibility, result from the spheroidal graphite iron structure. Different grades of ductile iron offer a range of mechanical properties, making them suitable for various castings and industries.

The ductile iron webpage provides detailed information about the mechanical properties and standards for ductile cast iron. Engineers use this resource to compare common ductile iron grades and select the best option for their needs. Manufacturers rely on these standards to produce high-quality ductile iron casting that meets global requirements.

Mechanical Properties

Tensile Strength

Tensile strength stands as one of the most critical physical and mechanical properties for ductile iron castings. Engineers measure tensile strength to determine how much force a material can withstand before it breaks. Ductile iron properties vary significantly between grades, which influences their suitability for different applications. For example, grade 60-40-18 offers an ultimate tensile strength of 460 MPa, while grade 80-55-06 reaches 600 MPa. This difference means grade 80-55-06 can handle higher loads and stress, making it ideal for components exposed to heavy wear or high-pressure environments.

| Property | Grade 60-40-18 | Grade 80-55-06 |

|---|---|---|

| Ultimate Tensile Strength (MPa) | 460 | 600 |

| Yield Strength (MPa) | 310 | 410 |

| Elongation at Break (%) | 20 | 6 |

| Brinell Hardness | 160 | 190 |

Designers often select ductile iron grades with higher tensile strength for gears, crankshafts, and heavy-duty machinery. These applications demand materials that resist deformation and maintain structural integrity under repeated stress. High tensile strength also contributes to better wear resistance, which extends the service life of cast components.

Note: Higher tensile strength usually means lower elongation, so engineers must balance strength with flexibility when choosing a grade.

Yield Strength

Yield strength defines the point at which ductile iron begins to deform permanently. This property is essential for parts that experience constant or fluctuating loads. Grade 80-55-06 provides a yield strength of 410 MPa, while grade 60-40-18 offers 310 MPa. Components with higher yield strength resist bending and stretching, which is crucial for structural supports and automotive parts.

Yield strength also affects wear performance. Materials with higher yield strength maintain their shape and resist surface damage during operation. For example, ductile iron pipes and fittings benefit from increased yield strength, as they must withstand internal pressure and external forces without failing.

Engineers consider yield strength when designing products for high ductility and impact resistance. Selecting the appropriate grade ensures that castings perform reliably in demanding environments.

Elongation

Elongation measures how much ductile iron can stretch before it fractures. This property indicates the material’s ability to absorb energy and deform without breaking. Grade 60-40-18 demonstrates high ductility, with an elongation at break of 20%. In contrast, grade 80-55-06 has an elongation of only 6%. Applications that require flexibility and resistance to sudden impacts often use grades with higher elongation.

| Property | Value |

|---|---|

| Tensile Strength (UTS) | Up to 1000 MPa |

| Elongation | Up to 20% in fully ferritic grades |

High ductility allows ductile iron castings to withstand shock loads and vibrations. This feature is especially important for infrastructure components, such as bridge supports and railways, where impact resistance and wear performance are vital. Engineers select grades with greater elongation for parts that must bend or flex during service.

Tip: Always match elongation and tensile strength to the application’s wear and impact resistance requirements.

Other Physical Properties

Ductile iron casting grades possess several physical properties that influence their performance in industrial applications. Engineers evaluate these characteristics to select the most suitable grade for each project.

Hardness

Hardness measures a material’s resistance to surface indentation and wear. Ductile iron grades display a range of Brinell hardness values, typically from 140 to 230 HB. Higher grades, such as ASTM A536 80-55-06, reach greater hardness levels, which improves abrasion resistance. Lower grades, like 60-40-18, offer moderate hardness, making them easier to machine.

| Grade | Brinell Hardness (HB) |

|---|---|

| 60-40-18 | 140 – 180 |

| 65-45-12 | 150 – 190 |

| 80-55-06 | 170 – 230 |

Impact Resistance

Impact resistance describes how well ductile iron absorbs sudden forces or shocks. Grades with higher elongation, such as 60-40-18, provide excellent impact resistance. These grades perform well in dynamic environments, including automotive suspension components and railway parts. Lower elongation grades may offer less impact resistance but compensate with higher strength.

Thermal Conductivity

Thermal conductivity indicates how efficiently ductile iron transfers heat. Most ductile iron grades conduct heat better than steel but less efficiently than pure iron. This property benefits applications that require heat dissipation, such as engine blocks and brake rotors. Consistent thermal conductivity helps prevent overheating and maintains structural stability.

Corrosion Resistance

Corrosion resistance determines how well ductile iron withstands exposure to moisture, chemicals, and harsh environments. The graphite structure in ductile iron provides natural resistance to corrosion, especially in grades with higher silicon content. Engineers often select ductile iron for water pipes, valves, and fittings due to its ability to resist rust and degradation.

Tip: When choosing a ductile iron grade, consider the operating environment. High humidity, chemical exposure, or extreme temperatures may require grades with enhanced corrosion or thermal properties.

Fatigue Strength

Fatigue strength refers to the ability of ductile iron to endure repeated loading cycles without failure. Grades with balanced strength and ductility, such as 65-45-12, offer reliable fatigue resistance. This property is essential for components that experience constant vibration or stress, including gears and crankshafts.

Density and Machinability

Ductile iron has a density of approximately 7.0 g/cm³. This value remains consistent across grades. Machinability varies with hardness; softer grades are easier to cut and shape, while harder grades require specialized tooling.

- Key physical properties to consider:

- Hardness

- Impact resistance

- Thermal conductivity

- Corrosion resistance

- Fatigue strength

- Density

- Machinability

Engineers analyze these physical properties alongside mechanical properties to ensure ductile iron castings deliver optimal performance. Selecting the right grade involves balancing these factors according to the demands of each application.

Ductile Iron Casting Applications

Infrastructure

Ductile iron plays a vital role in modern infrastructure projects. Engineers select ductile iron for bridges, roadways, and building frameworks because of its excellent strength and durability. Grade 65-45-12 stands out as a preferred choice for these projects. This grade offers a balance of tensile strength, yield strength, and elongation, making it suitable for structures that require both load-bearing capacity and flexibility.

| Property | Value |

|---|---|

| Tensile Strength | 65,000 psi |

| Yield Strength | 45,000 psi |

| Elongation | 12% |

| Typical Applications | Infrastructure projects, automotive components, pump bodies |

The nodular graphite in a ferritic matrix gives this grade optimal impact strength and good fatigue properties. Its excellent machinability allows for efficient fabrication of complex castings. Infrastructure projects benefit from ductile iron’s ability to absorb vibrations and resist cracking, which extends the service life of bridges, supports, and heavy-duty frames.

Automotive

Automotive manufacturers rely on ductile iron for many critical components. The material’s high strength and ductility make it ideal for parts that must withstand constant stress and impact. Ductile iron grades such as 65-45-12 and 80-55-06 are commonly used in the automotive sector. These grades provide the necessary mechanical properties for both safety and performance.

| Automotive Parts | Examples |

|---|---|

| Engine components | crankshafts, camshafts, cylinder heads, timing gears |

| Suspension parts | control arms, steering knuckles, wheel hubs |

| Transmission and drivetrain | differential carriers, gear housings, bearing caps |

Automotive engineers choose ductile iron for its fatigue resistance and ability to maintain shape under repeated loading. The nodular graphite structure enhances impact resistance, which is essential for suspension and drivetrain parts. Ductile iron castings also offer cost-effective solutions for high strength applications, reducing overall vehicle weight without sacrificing safety.

Pipe and Fittings

Ductile iron applications in pipe and fitting systems are widespread due to the material’s unique combination of strength and flexibility. Water supply, sewage, and gas distribution networks often use ductile iron pipes and fittings. The nodular graphite microstructure provides superior impact and fatigue resistance, which is crucial for underground and pressurized systems.

- Ductile iron is engineered for superior strength and flexibility, making it ideal for pipe and fitting applications.

- The nodular graphite microstructure provides impact and fatigue resistance, enhancing durability.

- Ductile iron exhibits higher resistance to cracking and deformation compared to standard cast iron.

- It offers better corrosion resistance, making it suitable for various environmental conditions.

Engineers select ductile cast iron for these systems because it resists cracking and deformation, even under heavy loads or shifting ground. The corrosion resistance of ductile iron ensures long-term reliability in harsh environments. These properties make ductile iron castings a top choice for municipal and industrial piping networks.

Note: Ductile iron’s versatility and mechanical properties support a wide range of typical applications in infrastructure, automotive, and piping systems.

Specialty Uses

Ductile iron’s versatility extends far beyond infrastructure, automotive, and piping systems. Many industries rely on specialty ductile iron grades for demanding and unique applications. These uses often require a careful balance of mechanical properties, such as high strength, superior ductility, or enhanced wear resistance.

Common Specialty Applications for Ductile Iron:

- Wind and Renewable Energy:

Wind turbine hubs and generator housings use high-strength ductile iron grades like ASTM A536 80-55-06. These components must withstand heavy loads, vibration, and fatigue over long periods. The material’s combination of strength and ductility ensures reliable performance in harsh outdoor environments. - Heavy Machinery and Mining Equipment:

Mining and earthmoving machinery require parts that resist abrasion and impact. Engineers often select grades such as 70-50-05 or 80-55-06 for gears, rollers, and wear plates. These grades provide the toughness needed to handle rocks, minerals, and constant mechanical stress. - Agricultural Implements:

Plowshares, tillage tools, and tractor components benefit from ductile iron’s wear resistance and shock absorption. Grades with moderate hardness and good elongation, like 65-45-12, help equipment last longer in the field. - Hydraulic and Pneumatic Systems:

Valve bodies, pump housings, and compressor parts use ductile iron for its machinability and pressure resistance. Grades such as 60-40-18 offer the right mix of flexibility and strength, allowing for precise manufacturing and reliable sealing. - Railway and Transit Components:

Rail clamps, couplers, and brake shoes require high impact resistance. Ductile iron grades with higher elongation, such as 60-40-18, absorb shocks and vibrations from constant train movement.

| Specialty Application | Typical Grade(s) | Key Property Needed |

|---|---|---|

| Wind turbine hubs | 80-55-06 | High strength, fatigue |

| Mining equipment | 70-50-05, 80-55-06 | Wear, impact resistance |

| Agricultural tools | 65-45-12 | Wear, ductility |

| Hydraulic valves | 60-40-18 | Machinability, sealing |

| Railway parts | 60-40-18 | Impact resistance |

Tip: Specialty applications often push materials to their limits. Engineers should always review the mechanical property requirements before selecting a ductile iron grade.

Ductile iron’s adaptability makes it a top choice for custom castings in industries that demand both performance and reliability. By matching the right grade to each specialty use, manufacturers ensure safety, efficiency, and long service life for critical components.

Selecting a Ductile Iron Casting Grade

Performance Needs

Selecting the right ductile iron casting grade starts with a clear understanding of performance needs. Engineers must evaluate the specific demands of each application. Heavy machinery, for example, requires materials that can handle dynamic loads, resist wear, and maintain shape under stress. The following table outlines key performance criteria for ductile iron used in demanding environments:

| Performance Criteria | Description |

|---|---|

| Impact Toughness | Measures a material’s ability to absorb energy under impact loading conditions, crucial for dynamic loading. |

| Hardness | Indicates wear resistance and the ability to withstand abrasive conditions. |

| Fatigue Strength | Maximum stress a material can withstand for repeated loading cycles without failure. |

| Creep Resistance | Ability to resist deformation over time under constant stress at elevated temperatures. |

| Modulus of Elasticity | Represents material stiffness and its response to applied loads. |

Engineers often select ductile iron grades with greater strength and ductility for parts exposed to high impact or vibration. For example, components in mining equipment or wind turbines must resist fatigue and wear over long periods. The right grade ensures reliable performance, safety, and a longer service life.

Tip: Always match the mechanical properties of ductile iron to the operational requirements of the project. This approach helps prevent premature failure and reduces maintenance needs.

Cost Considerations

Cost plays a significant role in the selection process for ductile iron casting grades. Project managers and engineers must balance initial investment with long-term savings. Several factors influence the total cost of using ductile iron:

- Ductile iron pipes have higher initial costs compared to steel pipes.

- Long-term operational costs are lower for ductile iron due to durability and reduced maintenance needs.

- The ease of repairs for ductile iron pipes can lead to significant cost savings over time.

Choosing a higher strength grade may increase upfront expenses, but it can also reduce the frequency of repairs and replacements. In large-scale manufacturing, these savings add up quickly. Engineers must consider both the purchase price and the expected lifespan of the material. By evaluating the total cost of ownership, decision-makers can select the most cost-effective ductile iron grade for their project.

Note: Investing in a suitable ductile iron grade often results in lower maintenance costs and improved reliability over the product’s lifetime.

Environmental Factors

Environmental conditions have a direct impact on the performance and longevity of ductile iron castings. Corrosion resistance is a key factor, especially for applications in water systems, marine structures, and chemical processing. The table below summarizes common corrosion mechanisms and their relevance to ductile iron:

| Corrosion Mechanism | Description |

|---|---|

| Uniform Corrosion | General corrosion affecting the entire surface in various environments. |

| Pitting Corrosion | Localized corrosion forming pits, leading to weakening of the material. |

| Microbiologically Influenced Corrosion | Corrosion accelerated by microorganisms, common in water or sewage systems. |

| Crevice Corrosion | Occurs in confined spaces with limited oxygen, leading to accelerated corrosion. |

| Applications in Corrosive Environments | Ductile iron is used in water systems, marine structures, chemical processing, agricultural equipment, and mining. |

| Measures to Improve Corrosion Resistance | Coatings, cathodic protection, material selection, proper design, and regular maintenance can enhance resistance. |

Engineers must assess the environment where the ductile iron casting will operate. For example, underground pipes may face uniform and pitting corrosion, while marine applications require protection against saltwater exposure. Selecting the right grade and applying protective measures, such as coatings or cathodic protection, can significantly extend the service life of ductile iron components.

Tip: Regular inspection and maintenance help preserve the integrity of ductile iron castings in harsh environments.

Expert Consultation

Selecting the optimal ductile iron casting grade often requires more than technical data and tables. Engineers and project managers benefit from consulting with industry experts who possess deep knowledge of material science and casting processes. These professionals analyze project requirements, environmental conditions, and performance expectations to recommend the most suitable grade.

Why Seek Expert Advice?

- Experts understand the nuances of international standards and grade equivalencies.

- They evaluate complex design challenges and suggest grades that balance strength, ductility, and cost.

- Specialists identify potential risks related to corrosion, fatigue, or impact, ensuring long-term reliability.

Tip: Early consultation with a metallurgist or casting engineer can prevent costly mistakes and delays.

Steps in the Expert Consultation Process

- Project Assessment

Experts review the application, load conditions, and operating environment. They ask targeted questions to clarify performance needs. - Material Selection

Specialists compare available ductile iron grades. They consider mechanical properties, machinability, and cost-effectiveness. - Design Optimization

Engineers collaborate with experts to refine casting designs. They address potential stress points and recommend grade adjustments if necessary. - Quality Assurance

Professionals advise on testing protocols and inspection standards. They help establish benchmarks for tensile strength, yield strength, and elongation.

| Consultation Step | Key Benefit |

|---|---|

| Project Assessment | Accurate identification of needs |

| Material Selection | Optimal grade recommendation |

| Design Optimization | Enhanced performance and durability |

| Quality Assurance | Reliable and consistent results |

Common Questions to Ask During Consultation

- What grade offers the best balance for my application?

- How will environmental factors affect material performance?

- What testing methods ensure the casting meets specifications?

- Can the selected grade reduce long-term maintenance costs?

Note: Expert consultation adds value at every stage of the project. It ensures that the chosen ductile iron grade aligns with both technical requirements and budget constraints.

Engineers who engage with experienced consultants gain confidence in their material choices. They minimize risks and maximize the lifespan of ductile iron castings. For complex or high-value projects, expert input proves essential for achieving optimal results.

Advantages and Limitations

Lower Grades

Lower grades of ductile iron offer several important benefits for municipal infrastructure and general engineering. These grades provide a combination of strength, ductility, and cost-effectiveness that appeals to many industries.

- Ductile iron manhole covers weigh about 30% less than traditional gray cast iron covers, making them easier to handle and install.

- The tensile strength of lower grades matches that of low-carbon steel, which improves performance in municipal applications.

- Service life for ductile iron pipes is twice as long as gray iron pipes and five times longer than ordinary steel pipes.

- Enhanced corrosion resistance and durability make these grades ideal for buried pipe installations.

- Lower maintenance needs result in long-term cost savings.

Despite these advantages, lower grades have some limitations in mechanical performance. For example, certain types, such as austempered ductile irons, may show reduced low-cycle fatigue lives as strain ratios increase. ADI austempered at 300°C is more vulnerable to mean stress effects, which can decrease fatigue strength under specific conditions.

Higher Grades

Higher grades of ductile iron deliver superior mechanical properties for demanding engineering applications. These grades stand out for their exceptional fracture toughness, tensile strength, and plasticity. Engineers rely on higher grades to ensure safety and reliability in challenging environments, such as nuclear power plants and high-speed rail systems. The increased strength and toughness of these grades allow them to withstand heavy loads, impacts, and extreme conditions. As a result, higher grades are often chosen for critical components where failure is not an option.

Trade-Offs

Selecting between lower and higher grades of ductile iron involves important trade-offs.

- Higher grades provide increased strength but may reduce ductility.

- Lower grades offer better ductility at the cost of lower strength.

Ductile cast iron stands out for its combination of tensile strength and ductility, making it suitable for applications that require toughness and impact resistance. Engineers must weigh the advantages of using ductile cast iron against the specific needs of each project. For applications needing flexibility and shock absorption, lower grades are often preferred. For projects demanding maximum strength and durability, higher grades become the better choice.

Tip: Always match the grade to the application’s requirements to maximize the advantages of using ductile cast iron.

Ductile Iron vs. Other Materials

Ductile Iron vs. Gray Iron

Engineers often compare ductile iron and gray iron when selecting materials for castings. The difference between ductile iron casting and cast iron casting lies in their microstructure and mechanical properties. Ductile iron contains nodular graphite, which gives it superior flexibility and toughness. Gray iron features flake graphite, resulting in higher brittleness and lower impact resistance.

The difference between ductile iron and grey iron becomes clear when examining tensile strength and impact resistance. Ductile iron grades, such as V-3 and V-4, outperform gray iron in both categories. The following table highlights these differences:

| Material Type | Tensile Strength (psi) | Impact Resistance (foot-pounds) |

|---|---|---|

| Gray Iron | 40,000 | 2 |

| Ductile Iron V-3 | 65,000 | 7 |

| Ductile Iron V-4 | 80,000 | 7 |

Ductile iron castings handle higher loads and absorb more energy during impacts. This makes them ideal for automotive parts, heavy machinery, and infrastructure components. Gray iron, while easier to machine, suits applications where vibration damping is important but high strength is not required. Engineers select ductile iron for projects demanding durability and safety.

Tip: Ductile iron’s nodular graphite structure provides enhanced toughness, making it a preferred choice for critical components exposed to dynamic forces.

Ductile Iron vs. Carbon Steel

Ductile iron and carbon steel serve similar roles in many industries, but they differ in cost, machinability, and performance. The difference between ductile iron and cast iron also extends to comparisons with steel. Ductile iron offers several advantages over carbon steel:

- Ductile iron is generally more affordable to manufacture than carbon steel.

- Ductile iron has better machinability compared to carbon steel.

Manufacturers choose ductile iron for its cost-effectiveness and ease of fabrication. Carbon steel, while strong and versatile, often requires more expensive processing and specialized tooling. Ductile iron’s superior machinability allows for complex shapes and precise dimensions, reducing production time and costs.

In terms of mechanical properties, carbon steel typically provides higher tensile strength and uniformity. However, ductile iron’s combination of strength, ductility, and impact resistance makes it suitable for castings that must withstand shock and vibration. Engineers often select ductile iron for water pipes, pump housings, and automotive components where cost and machinability are priorities.

Note: Ductile iron’s balance of affordability and performance supports its widespread use in infrastructure, transportation, and industrial equipment.

Selecting the right ductile iron casting grade depends on several factors:

| Factor | Description |

|---|---|

| Tensile Properties | Strength, yield, and elongation define mechanical performance. |

| Hardness | Brinell hardness reflects durability and wear resistance. |

| Microstructure | Spherical graphite improves ductility and toughness. |

| Composition | Alloying elements adjust properties for specific needs. |

| Cooling Rates | Casting methods influence final structure and strength. |

Matching grade to application improves reliability in automotive, infrastructure, and pipe systems. Reviewing international standards and consulting suppliers helps ensure the best choice for each project.

FAQ

What is the main difference between ductile iron and gray iron?

Ductile iron contains nodular graphite, which gives it higher strength and flexibility. Gray iron has flake graphite, resulting in brittleness and lower impact resistance. Engineers choose ductile iron for demanding applications that require toughness and durability.

How do engineers select the right ductile iron grade?

Engineers review mechanical properties such as tensile strength, yield strength, and elongation. They match these properties to the application’s requirements. Consultation with material experts helps ensure the best grade for each project.

Can ductile iron be used in corrosive environments?

Ductile iron resists corrosion better than many metals. For harsh environments, engineers often apply protective coatings or use grades with higher silicon content. Regular maintenance extends the lifespan of ductile iron components.

What are common applications for ductile iron castings?

Ductile iron castings appear in infrastructure, automotive parts, pipes, fittings, and specialty machinery. The material’s strength and ductility make it suitable for bridges, engine components, water systems, and mining equipment.

Does ductile iron offer good machinability?

Ductile iron provides excellent machinability, especially in lower grades. Manufacturers can shape and cut ductile iron efficiently. Harder grades may require specialized tools, but most grades allow for precise fabrication.

How do international standards affect ductile iron grade selection?

International standards, such as ASTM, ISO, and EN, define mechanical properties and grade equivalencies. Engineers use these standards to compare grades and ensure castings meet global requirements for quality and performance.

Is ductile iron more cost-effective than carbon steel?

Ductile iron usually costs less to manufacture and machine than carbon steel. Its durability and lower maintenance needs reduce long-term expenses. Engineers often select ductile iron for projects with strict budget constraints.

What physical properties make ductile iron unique?

Ductile iron combines high tensile strength, good elongation, and impact resistance. Its nodular graphite structure improves toughness. The material also offers reliable fatigue strength, corrosion resistance, and thermal conductivity.