Prevention and control of slag inclusion defects in lost foam gray cast iron production

The specific manifestations of slag inclusion defects in lost foam gray cast iron are as follows:

Appearance characteristics

Surface slag inclusion: Slag holes or inclusions of varying sizes appear on the surface of the casting, with irregular shapes, some in the form of dots, flakes, and some in the form of long strips. These slag inclusions are usually different in color from the surface of the casting, and may be black, gray or other different colors. They are not tightly bonded to the casting matrix, and some may even protrude from the surface of the casting and can be observed with the naked eye or a low-power magnifying glass.

Near-surface slag inclusion: Slag inclusions exist in the near-surface area of the casting. Although they are not directly exposed to the surface, they will be exposed after machining, causing pits, pitting and other defects on the processed surface, which seriously affects the machining accuracy and surface quality.

Internal conditions

Internal slag inclusion distribution: Through metallographic analysis or radiographic detection, it can be found that slag inclusions are randomly distributed inside the casting, some of which are concentrated in a certain area, and some are scattered throughout the casting. The size and number of slag inclusions also vary. Small slag inclusions may be only a few microns, while large slag inclusions may reach several millimeters or even larger. In severe cases, slag inclusion groups will form.

Bonding with the matrix: The bonding interface between the slag inclusion and the gray cast iron matrix is clear. There is no obvious metallurgical bonding between the slag inclusion and the matrix, but it exists in a mechanically mixed manner. During the force process, stress concentration is likely to occur between the slag inclusion and the matrix, reducing the mechanical properties of the casting.

Impact on processing performance

Increased processing difficulty: The presence of slag inclusions will cause the tool to vibrate and wear during the processing process, increase the roughness of the processing surface, and make it difficult to ensure the processing accuracy. Especially in high-speed cutting or precision processing, slag inclusions will cause frequent tool damage, increase processing costs and processing time.

Poor surface quality after processing: Even if the tool is not obviously damaged during the processing, the surface of the processed casting will have defects such as dark spots and scratches due to the presence of slag inclusions, affecting the appearance quality and assembly performance of the casting.

Impact on mechanical properties

Reduced strength and toughness: Slag inclusion, as an internal defect, destroys the continuity and density of gray cast iron. When subjected to stress, it will become a stress concentration point, resulting in reduced strength and toughness of the casting.

Impact on fatigue performance: Under cyclic loads, cracks are easily generated and extended at the slag inclusion, which greatly shortens the fatigue life of the casting and seriously affects its reliability under dynamic loads.

The main reasons for the slag inclusion defect in lost foam gray cast iron are as follows:

Raw materials

Quality of molten iron: If the molten iron contains more impurities, such as harmful elements such as sulfur and phosphorus, the probability of slag inclusion formation will increase. Scrap steel contains rust, and oxygen and other elements form oxidized slag during smelting, which can also easily cause slag inclusion defects in gray cast iron parts.

In terms of inoculants and alloys: Poor quality or improper addition may bring in impurities or produce reactive slag inclusions.

Melting process

Melting temperature: If the temperature is too high, the reaction between the molten metal and the furnace lining material will intensify, increasing the generation of slag inclusions; if the temperature is too low, the fluidity of the molten metal will be poor, which is not conducive to the floating and discharge of the slag inclusions.

Melting time: If the smelting time is too long, the contact time between the molten metal and the air will increase, and it will be easy to oxidize and form slag inclusions.

Slag treatment: If the slag is not removed thoroughly, the slag will remain in the molten iron, which will directly lead to slag inclusion defects.

Ladle problem: If there is residue in the ladle and it is not removed in time, the molten iron will melt the slag again, enter the mold during pouring, form slag inclusions, or the refractoriness of the ladle repair material is low, and there will be material drop and collapse during high-temperature molten iron to form slag defects.

Gating system and process

Gating system design: If the casting system is unreasonable, such as improper position and insufficient number of inner runners, the molten metal will flow unsteadily, produce turbulence, and involve gas and impurities to form slag inclusions.

Pouring speed: If the pouring speed is too fast, the impact force of the molten metal is large, which will wash the mold wall and cause impurities such as molding sand to be drawn into the molten metal; if the pouring speed is too slow, the molten metal will dissipate heat quickly during the pouring process, the temperature will drop, the fluidity will deteriorate, and the slag inclusions will not float up easily.

Pouring temperature: If the pouring temperature is too high, the oxidation of the molten metal will intensify, which will increase the formation of slag inclusions; if the pouring temperature is too low, the viscosity of the molten metal will increase, and the slag inclusions will be difficult to float out.

Casting aspect

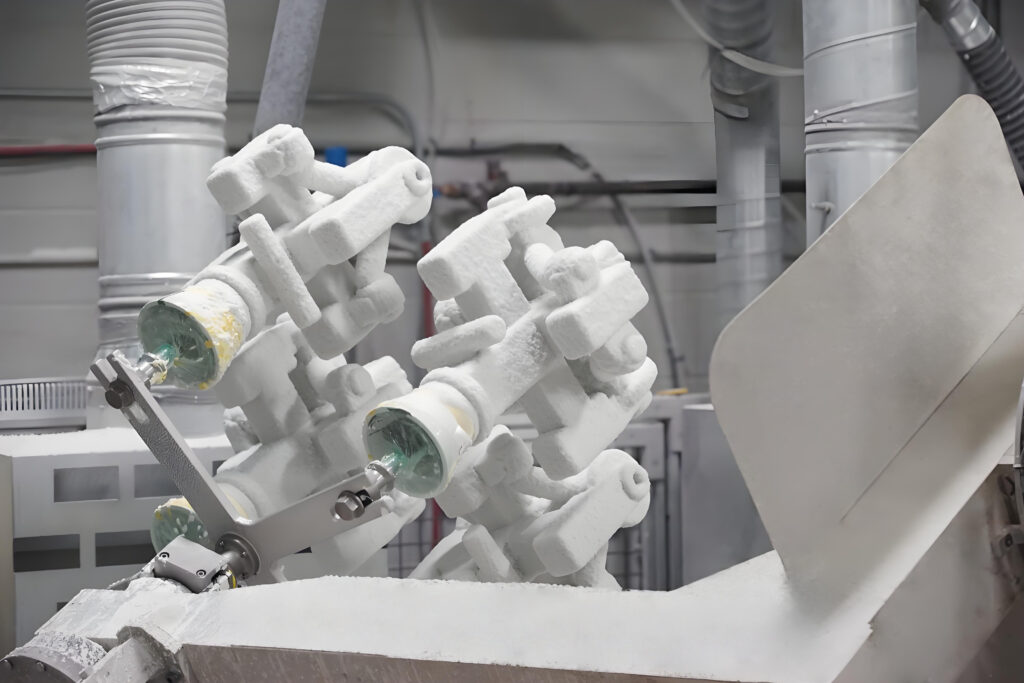

Paint quality: The paint has poor refractoriness, air permeability and other properties, and it is easy to fall off and enter the molten metal during the pouring process, forming slag inclusions.

Sand box air permeability: Poor air permeability will cause the gas in the mold to be unable to be discharged in time, forming pores or slag inclusions in the molten metal.

Process operation

Pattern quality: If the paint on the surface of the pattern falls off or cracks, or there are defects in the pattern itself, residues will be generated and enter the molten metal during pouring.

Vibration operation: During the sand filling and vibration process, if the operation is improper, the mold will be too compact or uneven, affecting the flow of the molten metal and the floating of the slag inclusions.

Prevention and control of slag inclusion defects in lost foam gray cast iron Specific prevention and control methods:

Raw material control

Strictly screen iron materials: Select high-quality pig iron and scrap steel to ensure that their chemical composition meets the requirements and the impurity content is low, reducing the slag inclusion source from the source.

Optimize inoculants: Select inoculants with stable quality and low impurity content, and accurately control their addition amount according to process requirements.

Melting process optimization

Accurately control smelting parameters: Reasonably control the smelting temperature and time to avoid excessive oxidation of the molten metal and intensified reaction with the furnace lining due to excessive temperature or long time.

Fully slag refining: Use multiple slag removal operations to ensure that the slag is clean. At the same time, refining agents can be used for refining treatment to further remove impurities and slag inclusions in the molten metal.

Improvement of pouring system and process

Scientific design of pouring system: the inner runner should be evenly distributed to avoid the molten metal directly rushing into the mold wall or core, so that the molten metal can fill the mold smoothly and reduce the slag inclusion.

Reasonable control of pouring parameters: determine the appropriate pouring speed and temperature according to the structure and process requirements of the casting. When pouring, the distance between the ladle nozzle and the pouring cup should be kept appropriate to avoid splashing and oxidation of the molten metal.

Improvement of casting quality

Selection of high-quality coatings: select coatings with high refractoriness, strong adhesion, good air permeability and not easy to fall off. Strictly prepare and apply the coating in accordance with the process requirements to ensure uniform coating and appropriate thickness.

Improve the air permeability of the sand box: reasonably set exhaust holes on the sand box or use molding sand with good air permeability to ensure that the gas in the mold can be discharged in time and reduce the formation of gas slag inclusion.

Process operation specifications

Ensure the quality of the pattern: the surface of the pattern should be smooth and defect-free, and the coating on the surface of the pattern should be evenly and firmly applied. During transportation and storage, avoid damage to the pattern.

Standardize compaction operation: Select appropriate compaction equipment and process parameters according to the size and complexity of the mold to ensure uniform and moderate compaction of the mold and avoid slag inclusion defects caused by excessive or insufficient compaction.