EN-GJL-250 is a grade of grey cast iron, according to EN 1561-2011 standard

Chemical composition

– Carbon (C): 3.16-3.30

– Silicon (Si): 1.79-1.93

– Manganese (Mn): 0.89-1.04

– Sulfur (S): 0.094-0.125

– Phosphorus (P): 0.120-0.170

Mechanical properties of Grey Cast Iron EN-GJL-250

– Tensile strength (Rm): 250 MPa

– Hardness (RH=1): 209 HB

– Sample size: Rod diameter: 30 mm

Other characteristics of Grey Cast Iron EN-GJL-250

– Good strength, wear resistance and heat resistance

– Excellent vibration damping performance

– Excellent casting performance, artificial aging treatment is required

– Application range: suitable for pump casings, containers, towers, flanges, stuffing boxes and covers, carbide towers, nitrification towers, etc. It is also used for processing beds, columns, cylinders, gears and parts that require surface quenching.

– Due to small thermal deformation, it is often used in high temperature environments.

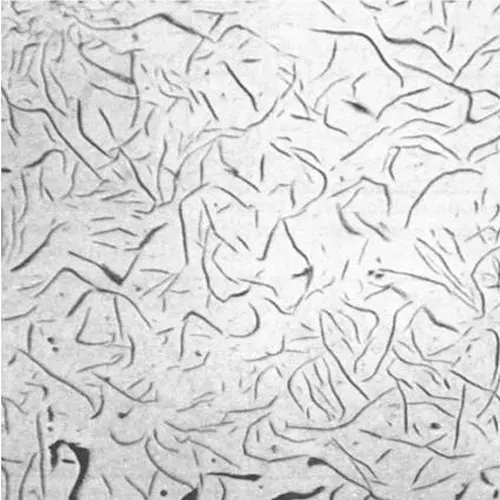

Specifications and organization of Grey Cast Iron EN-GJL-250

– Heat treatment specifications: (specified by the supplier, details provided for reference)

– Organization: flake graphite + pearlite

EN-GJL-250 quenching can reach HRC60, but gray cast iron is generally annealed or normalized without quenching. If hardness is required in a specific area, high-frequency or medium-frequency quenching can be performed.

– Medium-frequency quenching: quenching depth 3-5mm, hardness HRC50, and minimal deformation of the workpiece.

– High-frequency quenching: quenching depth 1-2mm, quenching temperature 850℃, surface hardness above HRC50; quenching temperature 900-1000℃, surface hardness up to HRC60.

Specifications and organization of Grey Cast Iron EN-GJL-250

– Heat treatment specifications: (specified by the supplier, details provided for reference)

– Organization: flake graphite + pearlite

EN-GJL-250 quenching can reach HRC60, but gray cast iron is generally annealed or normalized without quenching. If hardness is required in a specific area, high-frequency or medium-frequency quenching can be performed.

– Medium-frequency quenching: quenching depth 3-5mm, hardness HRC50, and minimal deformation of the workpiece.

– High-frequency quenching: quenching depth 1-2mm, quenching temperature 850℃, surface hardness above HRC50; quenching temperature 900-1000℃, surface hardness up to HRC60.

Heat treatment specifications of Grey Cast Iron EN-GJL-250

The heat treatment regulations of EN-GJL-250 are basically set by the supplier. Most of these castings are used in the cast or normalized state without quenching. If local hardening is desired, it can be done with high- or medium-frequency quenching:

Medium frequency quenching: hardening layer 3~5mm, hardness HRC50 or so, small deformation of the workpiece.

High-frequency quenching: 1~2mm hardening layer,hardenability can reach HRC50 or higher by quenching at 850 degrees; HRC60 may be reached by quenching 900~1000 degrees.

Use of Grey Cast Iron EN-GJL-250

Pump casings, containers, towers, flanges, stuffing boxes/glands, carbonizing towers, nitrifying towers and so on can be manufactured by EN-GJL-250. It is also applied to fabricate machine tool beds, columns, cylinders, gears and other parts demand surface quenching. Due to its low thermal deformation, it is commonly used for high temperature conditions.

Equivalent International standard of Grey Cast Iron EN-GJL-250

Gray cast iron is ASTM A48/A48M in the United States. The US equivalent of HT250 grey cast iron is either Grade 220 or Grade 260. These standards focus on The minimum tensile strength and yield strength, but the specifications for chemical composition and heat treatment are different.

In Japan, the standard for grey cast iron is JIS FC 250. It is similar to EN-GJL-250, both in terms of chemical composition and mechanical properties; however, there are differences in the specific values of its mechanical properties, and there may also be some differences in requirements based on the engineering practices of the Japanese domestic market.

The world equivalent of grey cast iron in the ISO standard is ISO 185. This standard specifies the classification, requirements and test methods of grey cast iron, and intended to be a uniform technical specification on the production and application of grey cast iron in the world. The properties of EN-GJL-250 grey cast iron are comparable in some grades to ISO 185 standard.