The matrix structure of QT450-10 cast ductile iron is within the range of pearlite content <30% and phosphorus eutectic content <1%. The change of matrix structure has little effect on the mechanical properties of ductile iron. However, the morphology of graphite in ductile iron, that is, the graphite spheroidization level, plays a decisive role in the change of mechanical properties of ductile iron.

The graphite distribution of ductile iron rarely appears in a single form in the same casting. The most common four basic forms are spherical, lumpy, flaky and thick flake. The combination of these forms of graphite can produce complex situations.

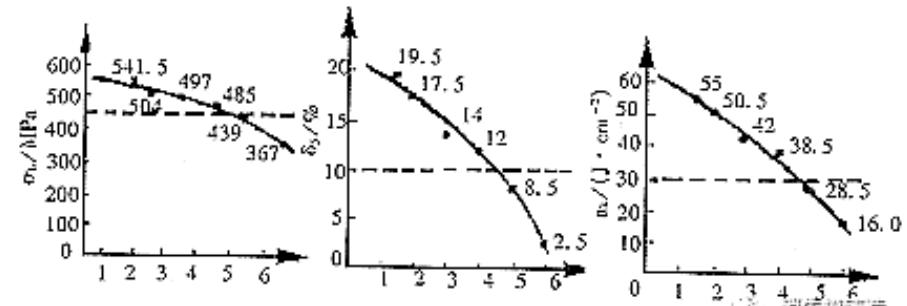

According to the statistical metallographic analysis results and mechanical property test data, for QT450-10 cast ductile iron, when its matrix structure is within the range of pearlite content <30%, phosphorus eutectic content <1%, and the size of graphite is within 3 levels. The mechanical properties of QT450-10 cast ductile iron with different spheroidization levels (graphite morphology) can be represented by the following figure.

Spheroidization level

Spheroidization level of QT450-10 cast ductile iron – mechanical properties curve

Conclusion

1. QT450-10 cast ductile iron with different metallographic structures are also different. Among them, the factor that has the greatest impact on the mechanical properties of ductile iron is the spheroidization level of its graphite. If the matrix structure of QT450-10 cast ductile iron is within the range of pearlite content <30% and phosphorus eutectic content <1%, the change of matrix structure has little effect on the mechanical properties of ductile iron.

2. QT450-10 cast ductile iron has qualified mechanical properties when its graphite spheroidization level is 1-4, under the conditions of pearlite content <30%, phosphorus eutectic <1%, and graphite size within 3 levels, and meets the requirements of σb≥450 MPa, δ5≥10%, aK≥30 J/cm2, and HB of 160-200. The higher the spheroidization level, the better the mechanical properties.

3. When the graphite of QT450-10 cast ductile iron is mainly in the form of thick flakes, its mechanical properties are relatively complex. If the thick flake graphite is completely dispersed, that is, the graphite spheroidization level is 5, the properties of the ductile iron are close to the requirements. For static parts such as motor housing, it can be considered for use on the premise that the graphite is completely dispersed after sampling and analysis of the body. If more than 70% of the thick flake graphite is dispersed, the properties of the ductile iron are slightly reduced. When the thick flake graphite is mixed and aggregated, the mechanical properties of the ductile iron are very poor. Generally speaking, for dynamic parts, when the graphite of ductile iron is mainly in the form of thick flakes, it should be judged as scrap.