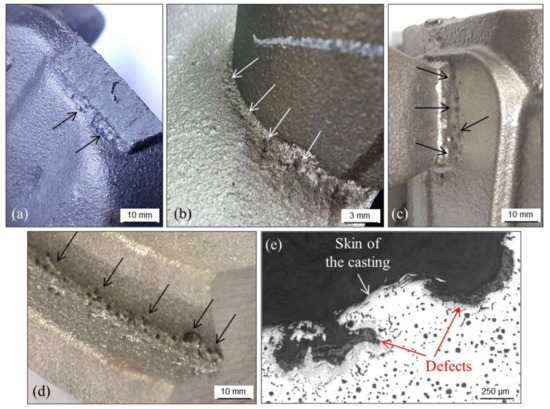

Casting Dimensional Accuracy

Conform to the drawing requirements, avoiding excessive machining allowances or dimensional deviations.

Exempt from deformation or warping, with clear contours and complete features (such as holes, slots, and threads).

Fit well with assembly components, eliminating interference.