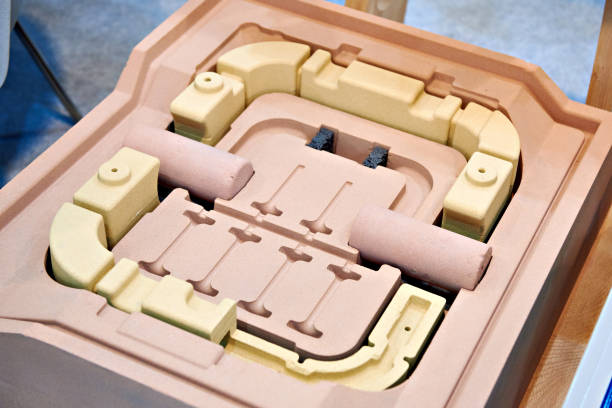

Resin sand casting parts vein defects causes and countermeasures

Appearance: veins are generally net-like or dendritic, with fine lines and varying depths, usually distributed on the surface of the casting, and sometimes deep into the casting.

Position: mostly occurs in the thick and large parts of the casting, corners, core surface, and the area where the molten metal is finally filled.

Surface condition: The surface of the casting at the vein is rough and uneven, and may be accompanied by raised or sunken sand particles.

Color change: Compared with the color of the casting matrix, the vein may be darker in color. This is because during the casting process, this part is affected by different degrees of oxidation or other physical and chemical changes.

The main reasons for the vein defects in cast iron parts produced by resin sand casting are as follows:

Resin sand

Too much resin added: the sand mold strength will be too high, the amount of gas generated by the decomposition of the resin at high temperature will increase, and the sand mold yield will deteriorate, which is easy to cause vein defects.

Improper amount of curing agent added: If too much is added, the curing speed is too fast, the internal stress of the sand mold is large, and veining is easy to occur; if too little is added, the curing is incomplete, the sand mold strength is insufficient, and veining will also occur under the impact of molten metal.

Poor quality of raw sand: If the particle size of the raw sand is uneven, the mud content is high, the shape is irregular, etc., it will affect the permeability and strength of the sand mold, resulting in veining defects.

In terms of molding technology

The compactness of the sand mold is too high: it will make the permeability of the sand mold worse, and the gas is difficult to discharge. At the same time, it increases the internal stress of the sand mold, which is easy to produce veining.

Improper demoulding operation: If the sand mold is subjected to excessive external force during demoulding, it will cause damage to the surface of the sand mold, and veining is easy to occur during the pouring process.

The sand mold is placed for too long: If the sand mold is placed for too long, the water on the surface of the sand mold will evaporate, the strength will be reduced, and veining is easy to occur during pouring.

In terms of casting technology

The pouring temperature is too high: it will increase the fluidity of the molten metal, increase the thermal shock to the sand mold, and easily produce veining.

Pouring speed is too fast: it will increase the impact of molten metal on the sand mold, easily damage the surface of the sand mold, and produce veins.

Unreasonable design of the pouring system: If the structure of the pouring system is unreasonable, the molten metal will flow unevenly in the sand mold, produce eddy currents and turbulence, and easily produce veins.

Casting structure

Uneven wall thickness of the casting: it will cause uneven shrinkage of the casting during solidification, produce internal stress, and easily produce veins in the parts with large wall thickness changes.

Complex casting structure: it will increase the difficulty of sand mold manufacturing, easily produce sand mold defects, and easily produce veins during pouring.

To solve the vein defects of resin sand casting cast iron parts, we can start from the following aspects:

Optimize the resin sand formula

Adjust the amount of resin added: Under the premise of ensuring the strength of the sand mold, try to reduce the amount of resin added, reduce the amount of gas generated at high temperature, and improve the yield of the sand mold.

Reasonable control of the amount of curing agent added: strictly control the amount of curing agent added according to the process requirements to ensure that the curing speed of the sand mold is moderate and avoid excessive internal stress or incomplete curing.

Select the right raw sand: Select raw sand with uniform particle size, low mud content and regular shape to improve the air permeability and strength of the sand mold.

Improve the molding process

Control the compactness of the sand mold: Use the right compaction method and compactness to ensure the strength of the sand mold, make it breathable and reduce the possibility of veining.

Standardize the demolding operation: The action should be gentle when demolding to avoid damage to the surface of the sand mold. If necessary, a demolding agent can be used to assist demolding.

Control the placement time of the sand mold: After the sand mold is made, it should be poured as soon as possible to avoid the sand mold being placed for too long, resulting in evaporation of surface moisture and reduced strength.

Adjust the pouring process

Control the pouring temperature: According to the material and structure of the casting, reasonably control the pouring temperature to avoid excessive thermal shock to the sand mold caused by excessive pouring temperature.

Adjust the pouring speed: The pouring speed should be moderate, which can ensure that the molten metal fills the mold smoothly without causing excessive impact on the sand mold.

Optimize the pouring system design: make the molten metal flow evenly in the sand mold to avoid eddy currents and turbulence.

Improve the structural design of castings

Optimize the wall thickness of castings: make the wall thickness of castings as uniform as possible and reduce sudden changes in wall thickness to reduce shrinkage stress during solidification.

Simplify the structure of castings: simplify the structure of castings and reduce the difficulty of sand mold manufacturing while meeting the use requirements.