Investment casting delivers precision metal components across industries where accuracy and quality matter most. Manufacturers rely on this ancient yet advanced process to create complex parts that traditional machining cannot achieve cost-effectively.

Studies show that investment casting can produce parts with tolerances as tight as ±0.003 inches while reducing material waste by up to 85% compared to conventional manufacturing methods. The global investment casting market reached $18.6 billion in 2023, reflecting its critical role in aerospace, automotive, and medical device manufacturing.

Industries benefit from investment casting’s ability to create intricate geometries, superior surface finishes, and consistent quality. The process eliminates secondary machining operations while supporting both prototype development and high-volume production runs.

For comprehensive technical standards and specifications, reference the ASTM A997 Standard Practice for Investment Castings Surface Acceptance, which provides detailed acceptance criteria for surface inspection of investment castings.

Key Takeaways

- Investment casting produces complex metal parts with exceptional precision and surface quality for critical applications

- Aerospace, automotive, medical, and industrial sectors rely on investment casting for components that demand tight tolerances

- The process supports diverse materials, including stainless steel, titanium, aluminum, and specialized alloys

- Investment casting reduces waste, eliminates assembly operations, and delivers cost-effective solutions for intricate designs

- Proper foundry selection ensures quality standards, material expertise, and production scalability for specific industry needs

Investment Casting Overview

What Is Investment Casting Used For?

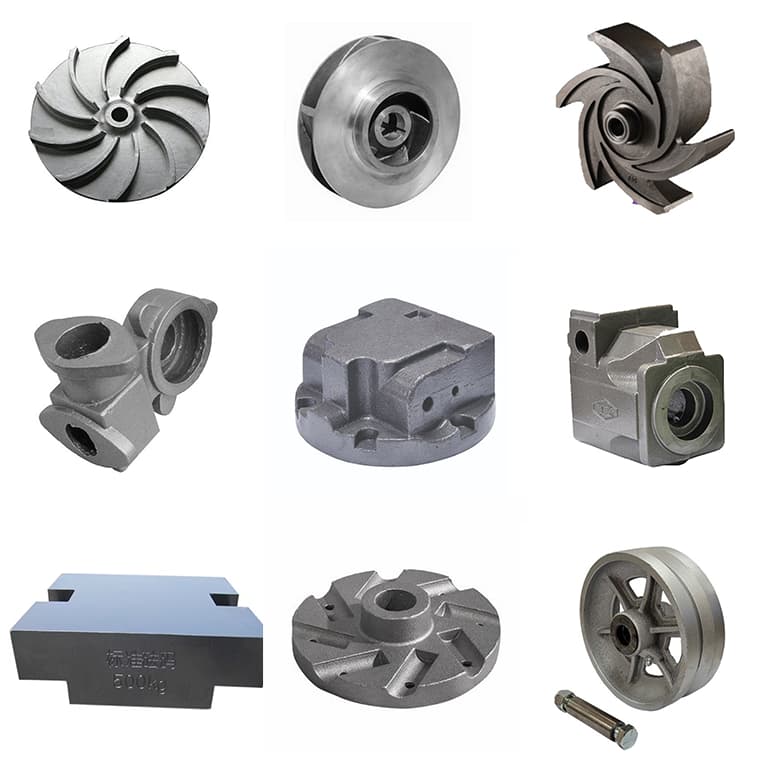

Investment casting, also known as lost-wax casting or precision casting, serves industries that require complex metal components with superior dimensional accuracy. Manufacturers use investment casting to produce parts ranging from tiny medical implants weighing grams to large aerospace components weighing hundreds of pounds.

The process creates components with intricate internal passages, thin walls, and complex geometries that would be impossible or extremely expensive to machine. Investment casting applications span critical sectors where part failure could have serious consequences.

Note: Investment casting enables manufacturers to produce near-net-shape components that require minimal finishing operations, reducing both cost and lead time.

Common applications include:

| Industry Sector | Typical Components | Key Requirements | Material Preferences |

| Aerospace | Turbine blades, brackets, housings | High strength, heat resistance | Titanium, superalloys, stainless steel |

| Automotive | Turbocharger wheels, suspension parts | Durability, weight reduction | Aluminum, steel alloys |

| Medical | Surgical instruments, implants | Biocompatibility, precision | Stainless steel 316L, titanium |

| Industrial | Pump impellers, valve bodies | Corrosion resistance, pressure ratings | Various stainless grades, bronze |

These measurable standards help manufacturers determine when investment casting provides the optimal solution for their specific component requirements. For detailed process information, visit Xometry’s comprehensive guide to investment casting.

How Investment Casting Works

Investment casting uses a multi-step process that begins with creating a wax pattern identical to the final part. Manufacturers inject wax into aluminum dies, creating precise replicas that include all design features, internal channels, and surface details.

The process follows these key stages:

- Wax patterns are assembled onto runners and gates to form casting trees.

- Ceramic shell material is applied in multiple coats to create a rigid mold.

- The assembly is heated to remove the wax, leaving a hollow ceramic shell.

- Molten metal is poured into the cavity and allowed to solidify.

Investment casting delivers superior results through:

Dimensional Accuracy: Parts typically achieve tolerances of ±0.13mm (±0.005″) without machining

Surface Quality: As-cast surfaces often meet finish requirements directly from the mold

Design Freedom: Complex internal features, undercuts, and thin sections are easily produced

Material Versatility: Process works with virtually any castable alloy

Tip: Leading manufacturers often choose investment casting for components where the cost of machining complex features would exceed the casting process expenses.

Recent industry data highlights growing investment casting adoption:

- The aerospace sector accounts for approximately 35% of global investment casting demand

- Automotive applications grew by 12% annually from 2020-2023 as manufacturers pursued weight reduction

- Medical device casting expanded 15% in 2023, driven by increasing implant demand

- Industrial equipment manufacturers increasingly specify investment cast components for pumps and valves

Investment casting success requires careful attention to:

- Pattern design optimization for manufacturing efficiency

- Shell material selection based on alloy requirements

- Gating system design for proper metal flow

- Heat treatment protocols for desired mechanical properties

- Quality control procedures, including dimensional inspection and metallurgical testing

For technical specifications and tolerance standards, consult Fractory’s detailed investment casting guide, which covers working principles and process parameters.

Investment casting provides manufacturers with unmatched capability to produce complex, high-quality metal components that meet demanding performance specifications across diverse industries.

Investment Casting Components and Materials

Pattern Systems and Tooling

Investment casting begins with precision wax patterns that determine final part quality. Manufacturers create aluminum dies that inject wax under controlled temperature and pressure conditions. These dies must account for both wax shrinkage and metal shrinkage to achieve target dimensions.

Pattern quality directly affects casting success. High-quality wax formulations maintain dimensional stability while providing smooth surface finishes. Assembly fixtures ensure consistent pattern orientation and runner attachment. The modular approach allows manufacturers to combine multiple parts on a single casting tree, optimizing production efficiency.

| Component Type | Function and Benefits | Quality Requirements | Industry Applications |

| Wax Patterns | Create exact part replica with all features | Dimensional accuracy ±0.025mm | All industries requiring precision casting |

| Aluminum Dies | Inject wax patterns consistently | Surface finish Ra 0.8μm or better | High-volume automotive and aerospace |

| Assembly Trees | Support multiple patterns for batch casting | Structural integrity through heating cycles | Cost-effective production runs |

Ceramic Shell Systems

Ceramic shell technology determines casting surface quality and dimensional accuracy. Primary coats use fine-grained materials that capture intricate pattern details. Backup coats provide structural strength to contain molten metal pressure during pouring.

Modern shell systems offer specialized solutions for different alloy families. Refractory materials resist chemical attack from reactive metals like titanium. Thermal expansion matching prevents shell cracking during rapid heating cycles.

Tip: Advanced ceramic shell systems enable casting of complex geometries with wall thicknesses as thin as 0.5mm while maintaining structural integrity.

Alloy Capabilities

Investment casting supports an extensive range of materials, each offering specific performance characteristics for targeted applications. Material selection depends on operating environment, mechanical requirements, and cost considerations.

Stainless steel grades dominate medical and food processing applications due to corrosion resistance and biocompatibility. Aerospace components utilize titanium alloys and superalloys for high-temperature performance. Automotive manufacturers specify aluminum alloys for weight reduction and steel alloys for strength requirements.

Surface Finishes and Quality Standards

Investment casting delivers superior surface finishes directly from the mold. Standard as-cast finishes range from 1.6 to 6.3 μm Ra, often eliminating secondary finishing operations. Specialized shell systems can achieve mirror-like finishes for decorative applications.

Quality assurance includes dimensional inspection, mechanical property verification, and non-destructive testing. Statistical process control ensures consistent results across production batches. Certificate of compliance documentation provides traceability for critical applications.

Investment casting materials and processes provide manufacturers with proven solutions for demanding component requirements across multiple industry sectors.

Investment Casting Applications by Industry

Aerospace and Defense Applications

Aerospace manufacturers rely on investment casting for critical components that operate under extreme conditions. Turbine engine parts represent the largest application segment, including turbine blades, vanes, and structural housings that must withstand temperatures exceeding 1000°C while maintaining precise tolerances.

Investment casting enables the production of hollow turbine blades with internal cooling passages that would be impossible to machine. These components utilize advanced superalloys like Inconel and Rene alloys that provide exceptional high-temperature strength and oxidation resistance.

Defense applications include missile components, aircraft structural parts, and weapons systems hardware. The process delivers consistent quality for components where failure is not acceptable. Investment casting supports both prototype development and production quantities for military programs.

Recent aerospace casting developments show significant growth in additive manufacturing integration, where 3D-printed wax patterns enable rapid prototyping and complex geometry optimization without traditional tooling costs.

Automotive Industry Uses

Automotive investment casting applications focus on performance components where weight reduction and strength are critical. Turbocharger wheels and housings represent major volume applications, as manufacturers pursue engine efficiency improvements through forced induction systems.

Suspension components, including control arms, steering knuckles, and brake calipers, utilize investment casting for optimal strength-to-weight ratios. The process enables integration of multiple features into single components, reducing assembly operations and potential failure points.

Electric vehicle development drives new casting applications for battery housings, motor components, and charging infrastructure hardware. These applications require specialized alloys with electromagnetic properties and thermal management capabilities.

Investment casting reduces automotive component weight by 15-25% compared to machined alternatives while maintaining equivalent performance characteristics.

Medical and Surgical Applications

Medical device manufacturers specify investment casting for surgical instruments, orthopedic implants, and diagnostic equipment components. Biocompatibility requirements limit material choices to approved grades of stainless steel 316L, titanium, and cobalt-chrome alloys.

Surgical instruments benefit from investment casting’s ability to produce complex shapes with integral features. Scissors, forceps, and specialized tools are cast near-net-shape, reducing manufacturing costs while ensuring consistent performance.

Orthopedic implants, including hip stems, knee components, and spinal hardware, utilize investment casting for patient-specific geometries. The process supports both standard sizes and custom implants based on medical imaging data.

Industrial Equipment Applications

Industrial manufacturers use investment casting for pump impellers, valve bodies, and fluid handling components that require corrosion resistance and pressure containment. The process enables complex internal flow passages that optimize hydraulic performance.

Chemical processing equipment relies on investment cast components made from specialized stainless steel grades and exotic alloys. These materials resist aggressive chemicals while maintaining structural integrity under extreme operating conditions.

Power generation applications include steam turbine components, gas turbine parts, and renewable energy hardware. Investment casting supports the production of large components weighing hundreds of pounds while maintaining dimensional accuracy requirements.

Investment casting applications continue expanding as manufacturers recognize the process advantages for complex, high-performance components across diverse industry sectors.

Investment Casting Selection and Quality Considerations

Choosing the Right Investment Casting Solution

Successful investment casting projects require careful evaluation of design requirements, material specifications, and production parameters. Engineers must consider part complexity, dimensional tolerances, surface finish requirements, and volume projections when selecting casting as the optimal manufacturing method.

Critical factors include:

Geometry Analysis: Parts with complex internal features, thin walls, or intricate external details benefit most from investment casting capabilities

Material Requirements: Operating environment determines alloy selection based on temperature, corrosion, and mechanical property needs

Volume Considerations: Investment casting becomes cost-effective for quantities ranging from prototype through high-volume production.

Quality Standards: Applications requiring tight tolerances and superior surface finishes favor the investment casting process

Case studies demonstrate that components with machining costs exceeding casting costs by 3:1 ratios typically justify investment casting selection. Professional foundry consultation ensures optimal process parameters and design optimization.

For detailed tolerance specifications, reference professional casting tolerance standards, which provide comprehensive guidelines for achieving precise dimensional control.

Quality Control and Standards

Investment casting quality begins with pattern accuracy and continues through every process step. Dimensional inspection using coordinate measuring machines verifies casting geometry against engineering drawings. Mechanical property testing confirms material performance meets specification requirements.

Modern quality systems include:

- Statistical process control for consistent dimensional results

- Non-destructive testing, including radiographic and penetrant inspection

- Metallurgical analysis for microstructure and composition verification

- Certificate of compliance documentation for traceability

Industry standards such as ASTM, AMS, and ISO specifications provide quality benchmarks for investment casting applications. Third-party certification ensures compliance with aerospace, medical, and automotive quality requirements.

Working with Investment Casting Foundries

Professional foundry selection significantly impacts project success. Experienced foundries provide design optimization recommendations, material expertise, and production scalability. Key evaluation criteria include industry certifications, quality systems, and manufacturing capabilities.

Tip: Leading foundries offer design for manufacturability consultations that optimize part geometry for casting while maintaining functional requirements.

Foundry capabilities to evaluate:

- Material expertise for specific alloy requirements

- Size and complexity limitations for target components

- Quality certifications for intended industry applications

- Production capacity for required delivery schedules

- Secondary operations, including machining and finishing

When selecting an investment casting foundry, manufacturers should prioritize suppliers with proven track records in their specific industry applications. Established foundries provide the expertise, quality systems, and production capabilities essential for successful casting projects across aerospace, automotive, medical, and industrial applications.

Conclusion

Investment casting serves as an essential manufacturing process for industries requiring precision metal components with superior quality and complex geometries. From aerospace turbine blades to medical implants, this versatile process delivers solutions that traditional manufacturing methods cannot achieve cost-effectively.

The technology continues advancing through improved materials, enhanced process control, and integration with digital manufacturing tools. As industries demand lighter, stronger, and more complex components, investment casting provides the capabilities manufacturers need to meet these challenging requirements.

For manufacturers evaluating component production options, investment casting offers proven advantages in dimensional accuracy, surface quality, and design flexibility. Success depends on proper material selection, design optimization, and foundry partnership to achieve optimal results for specific application requirements.

Frequently Asked Questions

Q: What tolerances can investment casting achieve?

A: Typically ±0.005 inches (±0.13mm), with some foundries achieving ±0.003 inches for critical dimensions. Much better than sand casting (±0.030 inches) and approaching CNC machining accuracy.

Q: How does the cost compare to machining?

A: Investment casting becomes cost-effective when machining costs exceed casting costs by a 3:1 ratio. Complex geometries justify the process even for smaller quantities.

Q: What’s the minimum achievable wall thickness?

A: As thin as 0.020 inches (0.5mm) depending on alloy and geometry. Stainless steel and aluminum allow thinner walls than superalloys or titanium.

Q: Does it work for both prototypes and production?

A: Yes. 3D-printed wax patterns eliminate tooling costs for prototypes. Aluminum dies ensure consistency for production quantities from single parts to hundreds of thousands annually.

Q: What secondary operations are needed?

A: Minimal due to near-net-shape capabilities. Light machining, heat treatment, surface treatments, and inspection. About 60-80% of features meet specifications without machining.