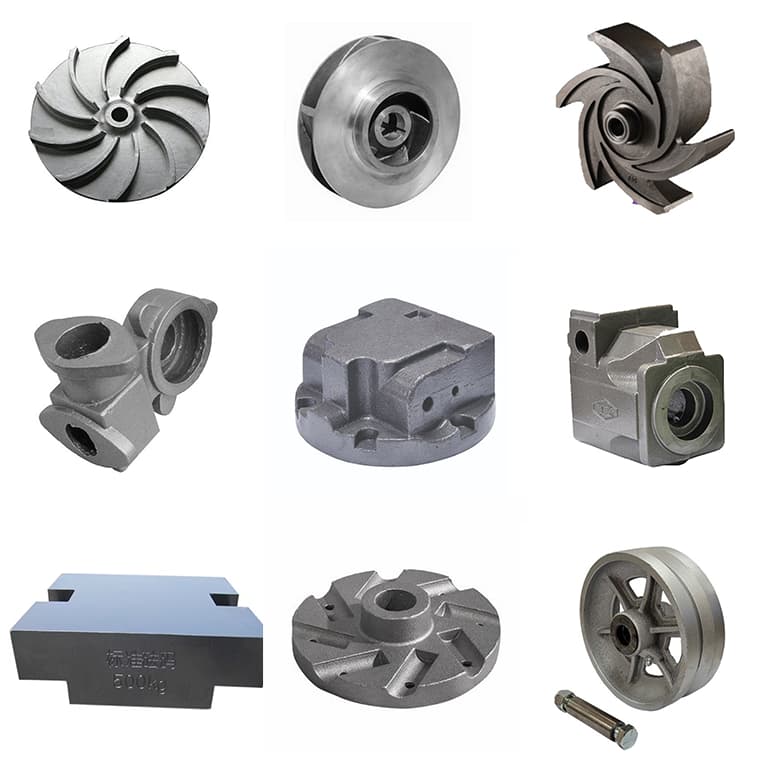

Steel casting is a manufacturing process that creates complex metal components by pouring molten steel into molds. This method produces durable parts with superior strength and versatility for industrial applications. Understanding steel casting helps manufacturers choose the right materials and processes for their specific needs.

Steel casting offers significant advantages over traditional manufacturing methods, including design flexibility, cost-effectiveness, and the ability to create intricate geometries. The global steel casting market continues to grow as industries demand stronger, more reliable components.

Key Takeaways

- Steel casting creates complex components with superior mechanical properties compared to grey iron casting and ductile iron casting alternatives

- The process offers four main methods: no-bake resin sand casting, green sand casting, lost foam casting, and investment casting

- Carbon steel casting provides excellent strength-to-weight ratios for industrial applications

- Proper material selection and process control ensure consistent quality and performance

- Steel casting serves critical applications in automotive, construction, marine, and heavy equipment industries

Steel Casting Overview

What Is Steel Casting?

Steel casting is a manufacturing process where molten steel is poured into molds to create solid metal components. This process differs from grey iron casting and ductile iron casting by offering superior mechanical properties and design flexibility. Steel casting produces components that can withstand higher stresses, impacts, and temperatures than traditional iron casting alternatives.

You will find steel casting essential when iron casting cannot provide adequate strength or durability. The process allows manufacturers to create complex internal passages, intricate geometries, and integrated features that would be impossible with conventional machining or fabrication methods.

How Steel Casting Works

Steel casting follows a systematic process that transforms raw materials into finished components:

- Pattern Creation: Engineers design patterns that match the desired final component shape

- Mold Preparation: Foundries prepare molds using various materials and techniques

- Melting: Steel is melted in furnaces and prepared for pouring

- Pouring: Molten steel is poured into the prepared molds

- Cooling: Components cool and solidify within the molds

- Finishing: Castings are removed, cleaned, and finished to specifications

The process creates components with excellent mechanical properties while maintaining dimensional accuracy and surface finish quality.

Steel Casting Process Methods

No-Bake Resin Sand Casting

No-bake resin sand casting uses chemically bonded sand molds that cure at room temperature. This process offers several advantages:

- Superior dimensional accuracy compared to traditional sand casting methods

- Excellent surface finish that reduces secondary machining requirements

- Complex geometries including internal passages and undercuts

- Consistent quality for both prototype and production runs

The process suits applications requiring tight tolerances and smooth surface finishes. Many manufacturers prefer this method for components with intricate internal features.

Green Sand Casting

Green sand casting employs clay-bonded sand molds containing moisture. This traditional method provides:

- Cost-effective production for simple to moderately complex shapes

- Environmental benefits through sand recycling and reuse

- Flexibility for design modifications and quick turnaround

- Proven reliability with decades of successful applications

Green sand casting works well for larger components and applications where moderate surface finish is acceptable.

Lost Foam Casting

Lost foam casting utilizes expandable polystyrene patterns that vaporize when molten steel is poured. This advanced technique offers:

- Eliminated core requirements for complex internal geometries

- Reduced machining due to excellent surface finish

- Design freedom for intricate shapes and thin walls

- Consistent quality with minimal dimensional variation

The process excels for components requiring complex internal cooling passages or intricate external features.

Investment Casting

Investment casting, also known as precision casting, creates wax patterns covered with ceramic shells. This method provides:

- Exceptional dimensional accuracy with tight tolerances

- Superior surface finish requiring minimal secondary operations

- Complex geometries including thin walls and fine details

- Material efficiency with minimal waste

Investment casting suits high-precision applications where quality and accuracy are paramount.

Steel Casting Materials and Grades

Carbon Steel Casting

Carbon steel casting represents the most versatile and widely used steel casting material. ASTM A216 standard covers three grades of carbon steel for pressure-containing applications:

Grade WCA (Low Carbon Steel)

- Carbon content: 0.25% maximum

- Excellent weldability and formability

- Applications: General structural components, brackets, housings

Grade WCB (Medium Carbon Steel)

- Carbon content: 0.30% maximum

- Balanced strength and toughness

- Applications: Pressure vessels, valves, and fittings

Grade WCC (High Carbon Steel)

- Carbon content: 0.25% maximum, controlled chemistry

- Enhanced strength and wear resistance

- Applications: High-stress components, wear parts

Steel Casting vs Iron Casting Comparison

| Property | Carbon Steel Casting | Grey Iron Casting | Ductile Iron Casting |

| Tensile Strength | 65,000-95,000 psi | 20,000-40,000 psi | 65,000-80,000 psi |

| Impact Resistance | Excellent | Poor | Good |

| Machinability | Good | Excellent | Good |

| Cost | Moderate | Low | Moderate |

| Weldability | Excellent | Poor | Fair |

Carbon steel casting provides superior performance when components require high strength, impact resistance, or welding capability.

Applications Across Industries

Automotive Industry

Steel casting serves critical automotive applications where strength and reliability are essential:

- Engine components: Cylinder heads, engine blocks, and transmission cases

- Suspension parts: Control arms, knuckles, and brackets

- Safety systems: Brake calipers, steering components, and structural reinforcements

The automotive industry relies on steel casting for components that must withstand high stresses, vibrations, and temperature variations.

Construction and Infrastructure

Construction applications utilize steel casting for structural and mechanical components:

- Structural connections: Beam connections, column bases, and joint hardware

- Heavy machinery: Crane components, excavator parts, and lifting equipment

- Infrastructure: Bridge components, tunnel segments, and marine structures

Steel casting provides the strength and durability required for long-term structural applications.

Marine and Offshore

Marine environments demand materials that resist corrosion while maintaining mechanical properties:

- Propulsion systems: Propeller hubs, rudder stocks, and strut bearings

- Deck equipment: Winches, cleats, and anchor handling systems

- Offshore platforms: Structural nodes, risers, and safety equipment

Steel casting delivers the combination of strength, toughness, and corrosion resistance needed for marine applications.

Mining and Heavy Equipment

Mining operations require components that withstand extreme wear and impact:

- Crushing equipment: Jaw plates, cone mantles, and impact bars

- Excavation tools: Bucket teeth, cutting edges, and wear plates

- Conveyor systems: Idler frames, pulleys, and support structures

Steel casting provides the durability and wear resistance essential for mining applications.

Quality Control and Standards

ASTM Standards for Steel Casting

ASTM standards provide comprehensive guidelines for steel casting materials and processes:

- ASTM A216: Carbon steel castings for pressure-containing parts

- ASTM A217: Alloy steel castings for high-temperature service

- ASTM A488: Welding procedures for steel castings

- ASTM A802: Surface discontinuity standards for steel castings

These standards ensure consistent quality and performance across different manufacturers and applications.

International Standards

ISO standards complement ASTM specifications for global applications:

- ISO 9001: Quality management systems for foundries

- ISO 14001: Environmental management in steel production

- ISO 17607: Structural steelwork execution standards

International standards facilitate global trade and ensure compatibility between different manufacturing regions.

Testing and Inspection

Comprehensive testing ensures steel casting quality:

Mechanical Testing

- Tensile strength and yield strength verification

- Impact testing for toughness evaluation

- Hardness testing for material consistency

Non-Destructive Testing

- Ultrasonic inspection for internal defects

- Magnetic particle testing for surface discontinuities

- Radiographic examination for porosity detection

Dimensional Inspection

- Coordinate measuring machine (CMM) verification

- Surface roughness measurement

- Geometric dimensioning and tolerancing (GD&T) compliance

Advantages of Steel Casting

Superior Mechanical Properties

Steel casting offers exceptional mechanical properties that surpass grey iron casting and ductile iron casting alternatives:

- Higher tensile strength: 65,000-95,000 psi vs 20,000-40,000 psi for grey iron

- Excellent impact resistance: Superior performance in shock loading conditions

- Temperature resistance: Maintains properties at elevated temperatures

- Fatigue resistance: Extended service life under cyclic loading

Design Flexibility

Steel casting accommodates complex geometries and integrated features:

- Internal passages: Complex cooling channels and fluid paths

- Thin walls: Lightweight designs without sacrificing strength

- Integrated features: Mounting bosses, flanges, and connection points

- Undercuts: Geometries impossible with traditional machining

Cost-Effectiveness

Steel casting provides economic benefits through:

- Near-net-shape production: Minimal secondary machining requirements

- Material efficiency: Reduced waste compared to subtractive manufacturing

- Consolidation: Multiple components combined into single castings

- Tooling amortization: Cost spreading over production volumes

Challenges and Solutions

Common Casting Defects

Steel casting can experience various defects that affect quality:

Porosity

- Causes: Gas entrapment, shrinkage, insufficient venting

- Solutions: Proper gating design, controlled pouring, vacuum assistance

Inclusions

- Causes: Contamination, inadequate slag removal, poor refining

- Solutions: Clean melting practices, effective filtration, quality control

Dimensional Variations

- Causes: Pattern accuracy, mold distortion, shrinkage control

- Solutions: Precision tooling, process simulation, temperature control

Process Optimization

Modern foundries employ advanced techniques to improve quality:

- Computer simulation: Predicting fill patterns and solidification

- Statistical process control: Monitoring and controlling variables

- Metallurgical analysis: Optimizing composition and microstructure

- Continuous improvement: Implementing lean manufacturing principles

Conclusion

Steel casting stands as an indispensable manufacturing process that transforms raw materials into complex, high-performance components across diverse industries. From automotive safety components to heavy machinery parts, steel casting provides the unique combination of strength, durability, and design flexibility that modern applications demand. The process continues to evolve with technological advances, incorporating automation, improved quality control, and enhanced alloy development to meet increasingly demanding requirements.

As industries continue to demand higher performance, improved sustainability, and enhanced cost-effectiveness, steel casting technology adapts to meet these challenges. Advanced process control, computer modeling, and innovative alloy development ensure that steel casting remains at the forefront of manufacturing technology.

For companies seeking reliable, high-quality steel casting solutions, partnering with an experienced custom steel casting supplier becomes essential. SHENGRONG combines decades of expertise with modern manufacturing capabilities to deliver superior steel castings that meet the most demanding specifications and quality requirements, ensuring optimal performance and long-term value for customers across all industries.