Gray cast iron carbide elimination annealing method

1. Preparation stage

Check the equipment: Before heating, carefully check the equipment condition of the electric furnace, including whether the heating element is normal, whether the temperature control system is accurate, whether the furnace door is well sealed, etc. Ensure that the equipment is fault-free, has no safety hazards, and can operate normally.

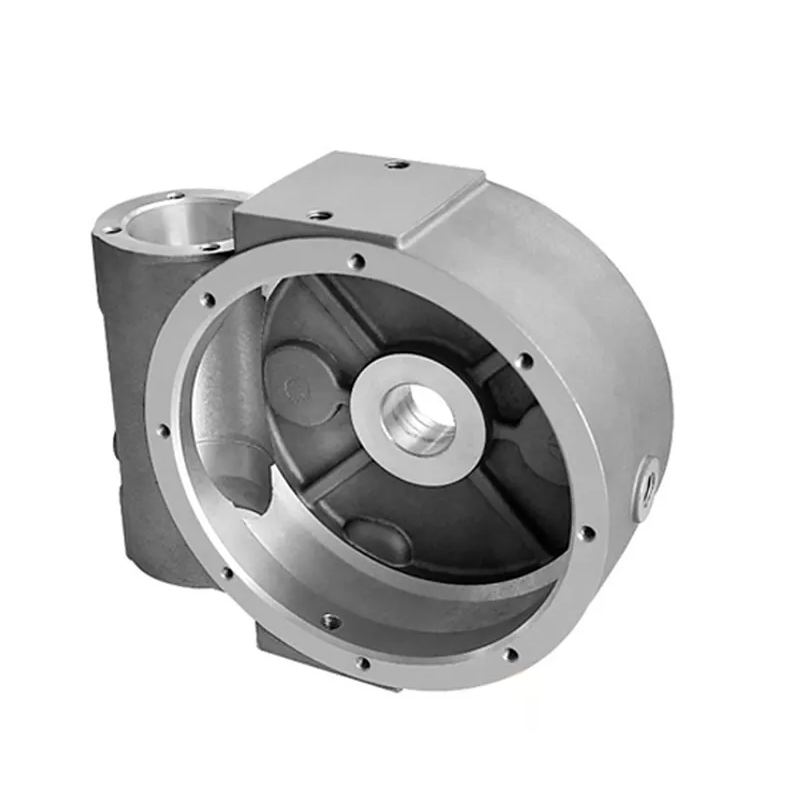

Loading the furnace: Place the gray cast iron castings in the electric furnace reasonably. Pay attention to maintaining appropriate spacing between castings so that heat can be evenly transferred, and avoid contact or collision between castings to cause damage. For castings with complex shapes or thin walls, pay special attention to the location and method of placement to prevent deformation or cracks due to uneven thermal stress during heating.

2. Initial heating stage

Set the heating speed: If the electric furnace has not been used for a long time, or the temperature in the furnace is low, the heating speed should not be too fast at the beginning. Generally speaking, before 600℃, the heating speed is best controlled at 50-100℃/hour. This is because a slower heating rate allows the casting to have enough time to adapt to temperature changes, reduce the generation of thermal stress, and reduce the risk of casting deformation and cracking.

Turn on the power and gradually increase the temperature: Turn on the power switch of the electric heating furnace and gradually increase the temperature in the furnace according to the set heating rate. During the heating process, pay close attention to the display of the temperature control system to ensure that the temperature rises steadily and meets the set speed.

3. Intermediate insulation stage

Insulation after reaching the transition temperature: When the temperature in the furnace rises to a certain level (such as about 500℃), insulation is carried out for a period of time. The purpose of insulation is to make the temperature inside and outside the casting tend to be uniform and reduce the temperature gradient. At the same time, it can also allow the casting to fully absorb heat and prepare for subsequent high-temperature treatment. The insulation time is generally 2-4 hours, and the specific time is determined according to factors such as the size, shape and material of the casting.

4. High temperature heating stage

Continue to heat up to the target temperature: After the intermediate insulation stage, continue to increase the temperature in the furnace until the target temperature of gray cast iron carbide elimination annealing is reached (usually 850-950℃). During the heating process, it is still necessary to maintain a stable heating rate to avoid excessive temperature fluctuations.

Keep the temperature stable: When the temperature in the furnace reaches the target temperature, keep the temperature stable within this range for a period of time. The insulation time is determined according to the wall thickness of the casting, generally 1-3 hours for every 25mm wall thickness. This stage is the key period for eliminating carbides. Sufficient insulation time can ensure that the carbides are fully decomposed and achieve the expected annealing effect.

5. Inspection after heating is completed

Temperature confirmation: After completing the high-temperature insulation stage, check again whether the temperature in the furnace is accurate and stable to ensure that the temperature conditions of the annealing process meet the requirements.

Appearance inspection: If conditions permit, the casting can be inspected for obvious defects such as deformation and cracks. If there are any abnormalities, the causes should be analyzed in time and corresponding measures should be taken.

When gray cast iron is annealed to eliminate carbides, the following aspects should be paid attention to when cooling:

1. Cooling rate:

Overall control: The cooling rate should not be too fast, and it is generally more appropriate to control it at 30-60℃ per hour. If the cooling speed is too fast, new thermal stress will be generated inside the casting, which may cause defects such as deformation and cracks in the casting. Especially for castings with complex shapes and uneven wall thickness, the cooling speed must be strictly controlled.

Material factors: For castings with low silicon content and low content of stable pearlite elements, due to their own material characteristics, the ability to resist stress during the cooling process is relatively weak, so the cooling speed should be slower to ensure the quality of the casting.

2. Choice of cooling method:

Furnace cooling: This is a more commonly used cooling method. After the annealing and insulation are completed, turn off the heating power supply and let the casting cool slowly with the furnace. This method can make the temperature of the casting change evenly throughout the cooling process and reduce the stress caused by uneven temperature. For most gray iron castings, furnace cooling can ensure good annealing effect.

Segmented cooling: For some castings with special requirements, segmented cooling can be used. For example, first cool at a faster speed in a higher temperature range, and then reduce the cooling speed in a lower temperature range. This can improve production efficiency to a certain extent, while also ensuring the quality of the casting. However, this cooling method needs to be reasonably adjusted and controlled according to the specific casting material, shape and size.

3. Control of temperature range:

Dwelling at key temperature points: During the cooling process, when the temperature drops to about 600℃, it is recommended to stay for a while. Because near this temperature, the structure of cast iron will undergo some changes, staying can make the structure change more fully, which is beneficial to improve the performance of the casting. The residence time is generally 1-2 hours, and the specific time depends on the specific situation of the casting.

Avoid sudden temperature changes: During the entire cooling process, avoid direct exposure of castings to cold air or cold water to prevent sudden temperature changes from causing defects such as cracks in the castings. If the cooling speed needs to be accelerated, a milder cooling method such as air cooling can be used, but it is also necessary to pay attention to controlling the speed and direction of air cooling.

4. Monitoring and detection:

Temperature monitoring: During the cooling process, pay close attention to the temperature changes to ensure that the cooling speed meets the requirements. Temperature sensors and other equipment can be used to monitor the temperature in the furnace in real time, and the cooling speed can be adjusted in time according to the monitoring results.

Appearance inspection: After the castings cool to room temperature, the castings should be inspected for defects such as cracks and deformations. If problems are found, the causes should be analyzed in time and appropriate measures should be taken to improve them.