Ductile iron castings are cast iron parts with unique microstructures. They are high-strength iron castings produced through a specific process based on ordinary gray iron. The material functions is close to steel. They are used for parts with complex forces and high requirements for strength, durability, and wear resistance, mainly used in the automotive, engineering, and construction industries. Ductile iron castings many grade number are: QT400-700, GG400-700, EN-GJS-400-700. Ductile iron classification: low-temperature type, ordinary type

Metallic Valve Seats

Machined from carbon steel, stainless steel, or Inconel alloys for high-pressure sealing.

Seal Retainers and Carriers

Custom-machined to securely house elastomeric or thermoplastic seals.

Gland Flanges and Stem Seals

Supporting dynamic sealing around valve stems in gate, plug, and ball valves.

Back-Up Rings

Metallic or thermoplastic rings that reinforce primary seals under pressure cycling.

Custom Seal Inserts

Precision grooves, O-ring housings, and interface surfaces to API 6A standards

Align’s seal-related components are used in:

Plug Valves (Stem Seals, Seat Carriers)

Gate Valves (Body Seals, Stem Packing Systems)

Choke Valves (Seal Retainers, Metallic Seats)

Surface and Subsea Wellhead Systems

Pressure Control and Flowback Equipment

In valve systems, seals are more than passive elements — they are the critical barrier between production fluids and the environment. Especially in manifold systems and pressure control skids, a single seal failure can halt operations or lead to safety events.

By ensuring that metallic seals, seal carriers, and gland components are precision-machined and material-matched to service conditions, Align helps our customers maximize cycle life and minimize unplanned maintenance.

Metallic Valve Seats

Machined from carbon steel, stainless steel, or Inconel alloys for high-pressure sealing.

Seal Retainers and Carriers

Custom-machined to securely house elastomeric or thermoplastic seals.

Gland Flanges and Stem Seals

Supporting dynamic sealing around valve stems in gate, plug, and ball valves.

Back-Up Rings

Metallic or thermoplastic rings that reinforce primary seals under pressure cycling.

Custom Seal Inserts

Precision grooves, O-ring housings, and interface surfaces to API 6A standards

Align’s seal-related components are used in:

Plug Valves (Stem Seals, Seat Carriers)

Gate Valves (Body Seals, Stem Packing Systems)

Choke Valves (Seal Retainers, Metallic Seats)

Surface and Subsea Wellhead Systems

Pressure Control and Flowback Equipment

In valve systems, seals are more than passive elements — they are the critical barrier between production fluids and the environment. Especially in manifold systems and pressure control skids, a single seal failure can halt operations or lead to safety events.

By ensuring that metallic seals, seal carriers, and gland components are precision-machined and material-matched to service conditions, Align helps our customers maximize cycle life and minimize unplanned maintenance.

Seals are critical to ensuring the reliability, safety, and efficiency of valves operating in oil and gas fields. Poor sealing performance can lead to leakage, production downtime, and even catastrophic well control failures.

Align Manufacturing supports valve OEMs and energy system builders with precision-machined metallic seals, gland components, and seal carriers built for extreme service conditions. Produced in facilities across India, Vietnam, and Thailand, our components meet U.S. engineering standards for oilfield performance, without the lead time uncertainty often associated with offshore sourcing.

In valve systems, seals are more than passive elements — they are the critical barrier between production fluids and the environment. Especially in manifold systems and pressure control skids, a single seal failure can halt operations or lead to safety events.

By ensuring that metallic seals, seal carriers, and gland components are precision-machined and material-matched to service conditions, Align helps our customers maximize cycle life and minimize unplanned maintenance.

We have state-of-the-art spectrometers to ensure the correct Mechanical Properties of metal alloys

We have state-of-the-art spectrometers to ensure the correct Mechanical Properties of metal alloys

1: Advanced technology and equipment standards

Advanced technology: Sand casting, precision casting, and lost foam casting process. Casting sizes according to customer requirements, weights ranging from 0.5kg to 10,000kg

Automation equipment: Equipped with automated production lines, intelligent melting furnaces (medium frequency/high frequency induction furnaces),

Inspection equipment: Chemical composition/spectrometer and mechanical property inspection equipment, three-coordinate measuring machine (CMM), X-ray flaw detector, spectrometer, ultrasonic testing and other high-end quality inspection methods.

2:Quality management system

ISO 9001 (quality management system)

IATF 16949 (automotive industry quality management system, such as automotive parts)

ASTM/EN/JIS and other international material standards.

3:Customization capability

Customized production according to customer drawings, customers only need to pay half of the mold fee to develop new castings. The mold time is short, only 20 days, and the casting time only 10 days. Machining 10 days.

Free express sample to customers, mass production after customer samples are confirmed to be fully qualified. Our company does not require customers to place a minimum order quantity, satisfying customers with a variety of choices

4:Competitive prices

Our company’s prices are very competitive in the industry, and the specific price depends on the casting drawing and the customer’s order quantity. Welcome to inquire

Carbon, silicon, manganese, sulfur, phosphorus, chromium, nickel, copper and other elements

Tensile strength, yield strength, elongation, hardness, impact strength

Three-coordinate inspection, non-destructive testing, pressure testing, etc.

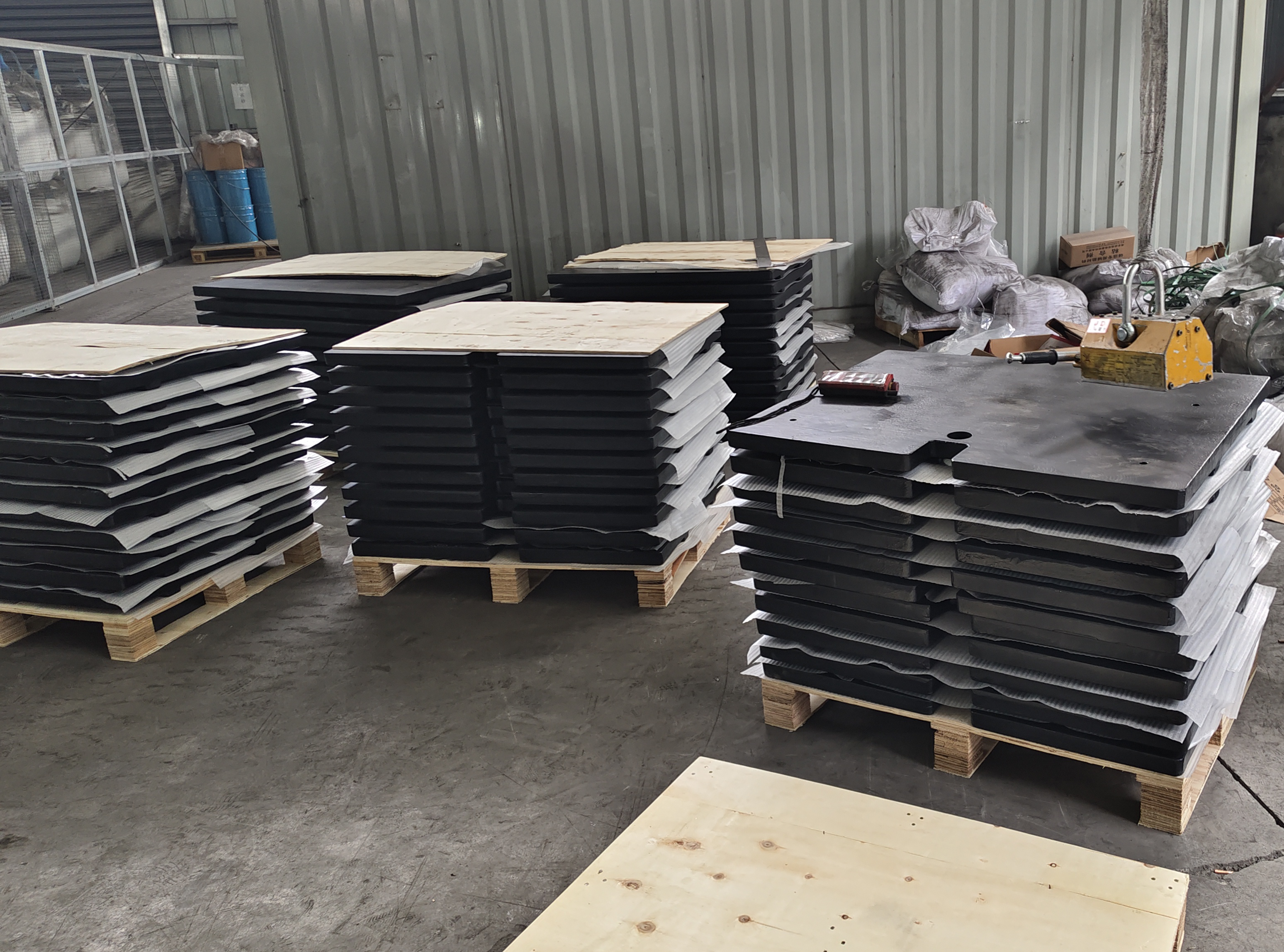

Every parts we will use anti-rust oil packing or primer, keep every parts in good condition after long time shipping.For small parts, we use wood box pallet packing.For bigger parts with pallet packing

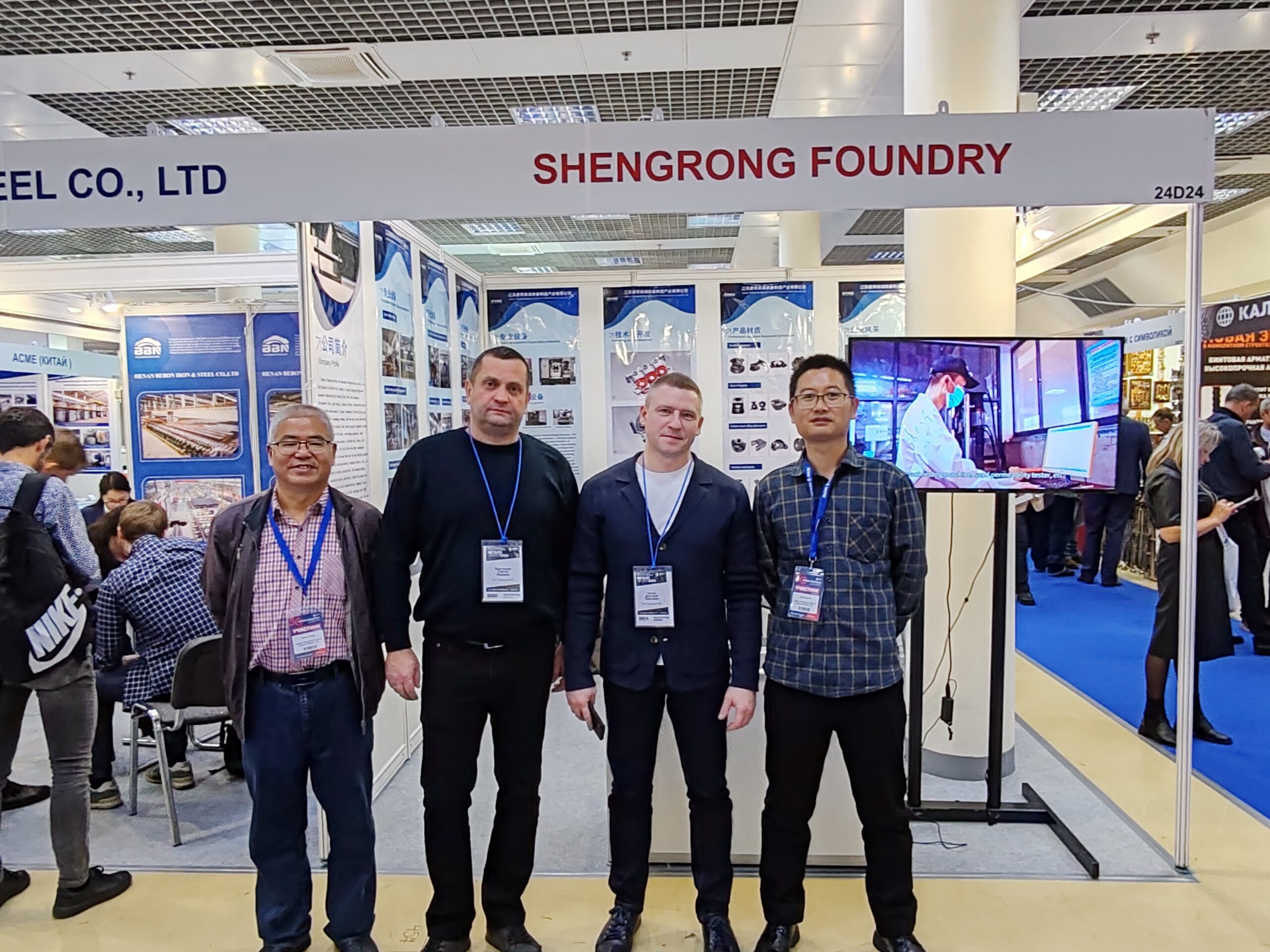

Jiangsu Shengrong High end Equipment Manufacturing Industry Co., Ltd is a professional iron casting foundry about 26,000 square meters, Investment of 80 million yuan,include intermediate frequency furnace, new east Seoul horizontal line, cast star horizontal line, micro crystal automatic casting machine, 40T mixer and 20T mixer, core-making machine, shot blasting machine, machining center, inclined rail lathe, slot machine, vertical lathe, flat rail lathe and other equipment.Testing equipment:spectrometer, tensile testing machine, hardness tester, etc., and supporting chemical testing laboratories. Mainly engaged in: mechanical parts, auto parts, industrial pump parts, bearings and transmission parts manufacturing. Company’s main business: QT450-12, 500-7, 600-3 ball mill castings and HT250, HT300 gray iron castings and cast steel, stainless steel and other business, with the increase of business volume, the production is not only to meet the main business, while the product after the process of product processing business development, so that enterprises diversified production. Now the company has more than 100 employees, including a professional management team and new product development.

CONTACT

Get In Touch