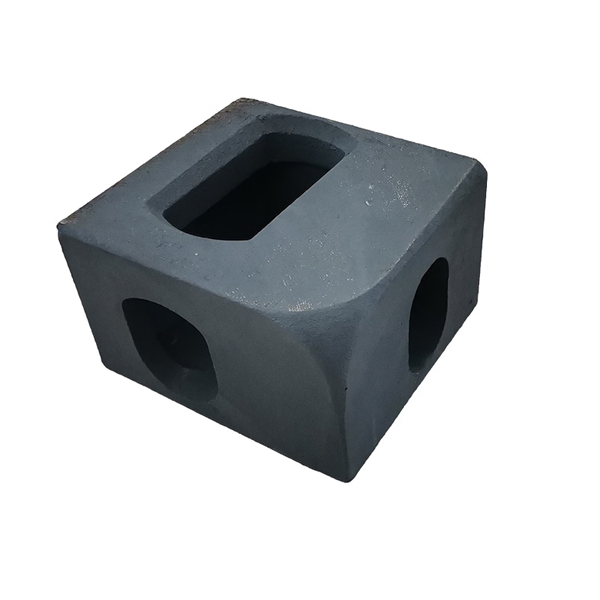

Jiangsu Shengrong specializes in producing mainstream ISO general container corner casting in the market. Made of JISSCW480 material and compliant with JISG5102 standards, corner fittings offer the following mechanical properties: tensile strength 430-600 MPa, yield strength >220 MPa, elongation >25%, cross-sectional shrinkage >40%, and low-temperature impact energy absorption (-20°C) ≥27J; (-40°C) ≥21J. We offer short delivery times, competitive pricing, and no minimum order quantity requirements.

1. High Strength and Durability: Typically constructed from high-strength steel (such as Q345B) or cast steel (such as ASTM A148 Grade 80-50), heat-treated (quenched and tempered) to enhance hardness and toughness.

Compliant with ISO 1161 standards, top corner fittings must withstand a maximum stacking load of 30 tons, while bottom corner fittings must withstand lifting and bolting forces. Optimized structural design avoids stress concentration and extends service life.

2. Precise Dimensional Tolerances: Complying with ISO 668 standards, this ensures seamless integration with lifting equipment, bolting equipment, and stacking systems, with tolerances within ±1mm.

3. Excellent Corrosion Resistance: Using hot-dip galvanizing (average zinc coating ≥ 80μm) or sandblasting with an epoxy zinc-rich primer, the product withstands 1000 hours of rust-free salt spray testing. Suitable for use in corrosive environments such as high salt spray, rainy, and humid sea transportation.

4. Strict Quality Certification: Certified by ISO 1161, CSC (International Convention for Safe Containers), and classification societies (such as BV and DNV).

Inspection Process: Includes ultrasonic testing (UT) and magnetic particle testing (MT) to detect internal defects, as well as tensile and impact testing to verify mechanical properties.

5. Structural Design: Integrated casting or forging processes eliminate weld weaknesses and cracking risks.

Emergency Compatibility: Quickly integrates with container rescue equipment (such as twist locks and spreaders) to ensure safe emergency operations.

Lifting and handling: Corner brackets work with lifting equipment (such as the twist locks on container cranes) to enable rapid lifting.

Stacking and securing: Upper and lower corner brackets nest together to support the stacking weight (up to 200 tons) and are secured with twist locks.

Transport securing: They connect to vehicle and vessel securing devices (such as lashing bars and locating cones) to prevent shifting.

Port loading and unloading: Cranes use corner brackets to lift containers, improving efficiency (for example, an STS quay crane can handle 30-50 containers per hour).

Intermodal transport: Containers can be quickly transferred between ships, railroad flatbeds, and trucks without unpacking.

Warehousing and stacking: Forklifts use corner brackets for stacking (typically 6-9 layers), saving space.

Specialty container applications: Reefer containers, tank containers, and other containers also rely on corner brackets for structural strength.

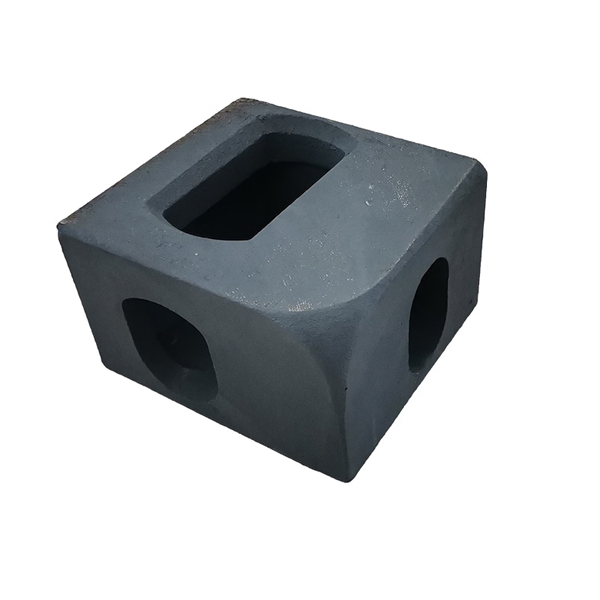

ISO corner fittings: Suitable for 20-foot and 40-foot standard containers.

Dimensions: Approximately 178mm x 162mm x 118mm.

Diameter of opening: Oval hole approximately 35mm x 26mm, used for twist lock or sling attachment.

Top fittings: Located at the top corners of the container, with retractable covers.

Bottom fittings: Located at the bottom of the container, directly connected to the stacking base or vehicle locking device.

Material: Cast steel (e.g., ZG230-450), heat-treated for increased strength and corrosion resistance.

Longitudinal load (when stacking): ≥150kN (approximately 15 tons per corner).

Transverse load (during transport): ≥75kN.

Lifting load: Meets dynamic impact requirements (typically designed with a safety factor of ≥2.5).

1. High Strength and Durability: Typically constructed from high-strength steel (such as Q345B) or cast steel (such as ASTM A148 Grade 80-50), heat-treated (quenched and tempered) to enhance hardness and toughness.

Compliant with ISO 1161 standards, top corner fittings must withstand a maximum stacking load of 30 tons, while bottom corner fittings must withstand lifting and bolting forces. Optimized structural design avoids stress concentration and extends service life.

2. Precise Dimensional Tolerances: Complying with ISO 668 standards, this ensures seamless integration with lifting equipment, bolting equipment, and stacking systems, with tolerances within ±1mm.

3. Excellent Corrosion Resistance: Using hot-dip galvanizing (average zinc coating ≥ 80μm) or sandblasting with an epoxy zinc-rich primer, the product withstands 1000 hours of rust-free salt spray testing. Suitable for use in corrosive environments such as high salt spray, rainy, and humid sea transportation.

4. Strict Quality Certification: Certified by ISO 1161, CSC (International Convention for Safe Containers), and classification societies (such as BV and DNV).

Inspection Process: Includes ultrasonic testing (UT) and magnetic particle testing (MT) to detect internal defects, as well as tensile and impact testing to verify mechanical properties.

5. Structural Design: Integrated casting or forging processes eliminate weld weaknesses and cracking risks.

Emergency Compatibility: Quickly integrates with container rescue equipment (such as twist locks and spreaders) to ensure safe emergency operations.

Lifting and handling: Corner brackets work with lifting equipment (such as the twist locks on container cranes) to enable rapid lifting.

Stacking and securing: Upper and lower corner brackets nest together to support the stacking weight (up to 200 tons) and are secured with twist locks.

Transport securing: They connect to vehicle and vessel securing devices (such as lashing bars and locating cones) to prevent shifting.

Port loading and unloading: Cranes use corner brackets to lift containers, improving efficiency (for example, an STS quay crane can handle 30-50 containers per hour).

Intermodal transport: Containers can be quickly transferred between ships, railroad flatbeds, and trucks without unpacking.

Warehousing and stacking: Forklifts use corner brackets for stacking (typically 6-9 layers), saving space.

Specialty container applications: Reefer containers, tank containers, and other containers also rely on corner brackets for structural strength.

ISO corner fittings: Suitable for 20-foot and 40-foot standard containers.

Dimensions: Approximately 178mm x 162mm x 118mm.

Diameter of opening: Oval hole approximately 35mm x 26mm, used for twist lock or sling attachment.

Top fittings: Located at the top corners of the container, with retractable covers.

Bottom fittings: Located at the bottom of the container, directly connected to the stacking base or vehicle locking device.

Material: Cast steel (e.g., ZG230-450), heat-treated for increased strength and corrosion resistance.

Longitudinal load (when stacking): ≥150kN (approximately 15 tons per corner).

Transverse load (during transport): ≥75kN.

Lifting load: Meets dynamic impact requirements (typically designed with a safety factor of ≥2.5).

Material Selection: High-strength steel (such as Q345B or ASTM A572 Grade 50) is typically used, requiring good weldability and low-temperature impact resistance.

Casting Process (common in mass production)

Mold Making: Sand or metal molds are created based on the 3D drawing of the corner piece.

Melting and Pouring: Molten steel (approximately 1600°C) is poured into the mold to form the blank.

Sand Cleaning: Removes sand and scale from the casting surface.

Rough Machining: Milling and lathes are used to remove excess material and achieve initial shaping.

Fine Machining: CNC machining precisely processes key areas such as keyholes and bevels, maintaining tolerances within ±0.5mm.

Drilling and Tapping: Produces standard-sized keyholes (such as the 8-hole position specified in ISO 1161).

Surface Treatment: Sandblasting or shot blasting removes oxide layers to improve adhesion of subsequent coatings. Normalizing/Quenching + Tempering: Increases hardness (typically HB 180-240) and tensile strength (≥500 MPa).

Nondestructive Testing: Ultrasonic or magnetic particle inspection for internal cracks.

Hot-dip galvanizing: A common process with a zinc coating thickness of ≥80 μm and a 2000-hour salt spray test.

Dimensional Inspection: Uses a coordinate measuring machine (CMM) to verify critical dimensions.

Load Testing: Vertical and horizontal tensile testing is performed on random samples (e.g., top corner fittings must withstand a 150 kN load).

Certification: Provide third-party inspection reports (e.g., BV, SGS).

Material Standard: Cast steel (such as ASTM A27 Gr.65-35 or GB/T 11352 ZG270-500) is used. A material report is required to verify the chemical composition (C, Si, Mn, S, P, etc.) and mechanical properties (tensile strength ≥ 500 MPa, elongation ≥ 12%).

Casting Process: Lost foam or sand casting is used to ensure the absence of defects such as pores, slag inclusions, and shrinkage. X-ray or ultrasonic testing is required for spot inspection.

Mold Management: Regularly inspect mold dimensions for wear and ensure that key corner dimensions (such as hole diameter and hole spacing) comply with ISO 1161 standards (tolerance ±1mm).

Heat Treatment: Normalizing and tempering to eliminate internal stresses. Hardness is controlled between HB140-210 to avoid brittle cracking caused by excessive hardness.

Surface Treatment: Shot blasting followed by hot-dip galvanizing (zinc layer ≥ 80μm) or spraying with anti-corrosion paint. Salt spray testing must be performed for 720 hours with no red rust.

Top corner fitting hole diameter Φ50 ± 0.2mm, bottom corner fitting hole diameter Φ60 ± 0.2mm.

Corner fitting mating surface flatness ≤ 0.5mm to ensure stress-free welding to the box.

Positioning Accuracy: Diagonal deviation of the four corner fittings ≤ 5mm (20-foot box) to prevent twist lock misalignment during lifting.

Static load test: Vertical load ≥ 150kN (1.5x safety factor), lateral load ≥ 75kN, no plastic deformation.

Fatigue test: No cracks after 10,000 simulated lifting cycles (referring to ISO 1496).

Impact toughness: Charpy impact test ≥ 27J at -20°C, ensuring low-temperature performance.

1: Advanced technology and equipment standards

Advanced technology: Sand casting, precision casting, and lost foam casting process. Casting sizes according to customer requirements, weights ranging from 0.5kg to 10,000kg

Automation equipment: Equipped with automated production lines, intelligent melting furnaces (medium frequency/high frequency induction furnaces),

Inspection equipment: Chemical composition/spectrometer and mechanical property inspection equipment, three-coordinate measuring machine (CMM), X-ray flaw detector, spectrometer, ultrasonic testing and other high-end quality inspection methods.

2:Quality management system

ISO 9001 (quality management system)

IATF 16949 (automotive industry quality management system, such as automotive parts)

ASTM/EN/JIS and other international material standards.

3:Customization capability

Customized production according to customer drawings, customers only need to pay half of the mold fee to develop new castings. The mold time is short, only 20 days, and the casting time only 10 days. Machining 10 days.

Free express sample to customers, mass production after customer samples are confirmed to be fully qualified. Our company does not require customers to place a minimum order quantity, satisfying customers with a variety of choices

4:Competitive prices

Our company’s prices are very competitive in the industry, and the specific price depends on the casting drawing and the customer’s order quantity. Welcome to inquire

Carbon, silicon, manganese, sulfur, phosphorus, chromium, nickel, copper and other elements

Tensile strength, yield strength, elongation, hardness, impact strength

Three-coordinate inspection, non-destructive testing, pressure testing, etc.

Every parts we will use anti-rust oil packing or primer, keep every parts in good condition after long time shipping.For small parts, we use wood box pallet packing.For bigger parts with pallet packing

Jiangsu Shengrong High end Equipment Manufacturing Industry Co., Ltd is a professional iron casting foundry about 26,000 square meters, Investment of 80 million yuan,include intermediate frequency furnace, new east Seoul horizontal line, cast star horizontal line, micro crystal automatic casting machine, 40T mixer and 20T mixer, core-making machine, shot blasting machine, machining center, inclined rail lathe, slot machine, vertical lathe, flat rail lathe and other equipment.Testing equipment:spectrometer, tensile testing machine, hardness tester, etc., and supporting chemical testing laboratories. Mainly engaged in: mechanical parts, auto parts, industrial pump parts, bearings and transmission parts manufacturing. Company’s main business: QT450-12, 500-7, 600-3 ball mill castings and HT250, HT300 gray iron castings and cast steel, stainless steel and other business, with the increase of business volume, the production is not only to meet the main business, while the product after the process of product processing business development, so that enterprises diversified production. Now the company has more than 100 employees, including a professional management team and new product development.

CONTACT

Get In Touch