Gray cast iron is a versatile engineering material recognized for its graphitic microstructure, which gives it a distinct gray fracture surface. Its composition, usually 2.5–4% carbon and 1–3% silicon, shapes its mechanical properties and appearance. Higher carbon and silicon levels increase the amount of graphite, improving castability but reducing strength. During fracture, the graphite creates deep grooves, leading to a unique mix of ductile and brittle features. Engineers often select gray cast iron for its balance of castability, machinability, and cost-effectiveness.

Key Takeaways

- Gray cast iron features a unique graphitic microstructure, which provides a gray appearance and affects its mechanical properties.

- The presence of graphite flakes enhances machinability, making gray cast iron easy to cut and shape during manufacturing.

- Gray cast iron excels in shock absorption and vibration damping, making it ideal for machine tool beds and engine blocks.

- High thermal conductivity allows gray cast iron to efficiently manage heat, making it suitable for engine components and cookware.

- Cost-effectiveness is a key advantage of gray cast iron, as it is generally cheaper to produce than many other metals.

- Different types of gray cast iron, such as ferritic and pearlitic, offer varying strengths and hardness for specific applications.

- Quality control measures, including non-destructive testing, ensure that gray cast iron products meet performance standards.

- Regular inspection and maintenance of gray cast iron components can help detect wear and prevent unexpected failures.

Gray Cast Iron Overview

Definition

Gray cast iron stands out as a widely used cast iron material in engineering. Its most distinguishing feature is the graphitic microstructure, which contains graphite flakes embedded in a matrix of ferrite or pearlite. These graphite flakes give the material its characteristic gray appearance on fractured surfaces. The unique structure of gray cast iron results in a combination of good castability, excellent machinability, and effective vibration damping.

Note: The gray color seen on broken surfaces comes from the graphite flakes, which reflect light differently than the surrounding metal.

Key Features

Engineers value gray cast iron for several key features that set it apart from other cast irons:

- Graphite Flakes: The presence of graphite flakes in the microstructure provides natural lubrication during machining. This property makes gray cast iron easy to machine and shape.

- Shock Absorption: The graphite structure absorbs vibrations and shocks well. Machine tool beds and engine blocks often use this material for its damping properties.

- Thermal Conductivity: Gray cast iron conducts heat efficiently. This feature makes it suitable for products like engine blocks and cookware.

- Cost-Effectiveness: Manufacturers can produce gray cast iron at a lower cost compared to many other metals.

- Mechanical Behavior: The shape and distribution of graphite flakes influence strength and ductility. Thin, parallel flakes improve tensile strength and ductility, while irregular flakes can reduce toughness.

The table below highlights how gray cast iron compares to other types of cast iron:

| Characteristic/Property | Gray Cast Iron | Other Cast Irons (e.g., White Cast Iron) |

|---|---|---|

| Microstructure | Contains graphite flakes in a matrix of ferrite or pearlite | Different microstructures (e.g., cementite) |

| Appearance | Gray appearance on fracture surfaces | Varies (e.g., white appearance in white cast iron) |

| Machinability | Good due to graphite acting as a lubricant | Generally lower than gray cast iron |

| Damping Properties | Excellent, suitable for machinery bases | Varies, often less effective |

| Thermal Conductivity | High, suitable for cooking pots and engine blocks | Varies, often lower |

| Cost-Effectiveness | Generally cheaper to produce | Varies, often more expensive |

| Tensile Strength | Low compared to other metals | Higher in white cast iron |

| Wear Resistance | Poor due to graphite flakes | Generally better in other cast irons |

Types

Gray cast iron comes in several types, each with unique properties based on the matrix structure. The main types include:

| Type of Gray Cast Iron | Matrix Organization | Properties |

|---|---|---|

| Ferritic Gray Cast Iron | Ferritic matrix | Lowest strength and hardness; seldom used. |

| Pearlitic Gray Cast Iron | Pearlitic matrix | Higher strength and hardness; used for important iron castings. |

| Ferrite and Pearlite Gray Cast Iron | Ferrite and pearlite matrix | Mechanical properties worse than pearlitic gray cast iron. |

- Ferritic Gray Cast Iron: This type contains mostly ferrite in its matrix. It offers the lowest strength and hardness among the types. Manufacturers rarely use it for demanding applications.

- Pearlitic Gray Cast Iron: This type features a pearlitic matrix, which increases strength and hardness. Engineers often select pearlitic gray cast iron for critical components that require higher mechanical performance.

- Ferrite and Pearlite Gray Cast Iron: This type combines both ferrite and pearlite in the matrix. Its mechanical properties fall between the ferritic and pearlitic types.

Tip: Selecting the right type of grey cast iron depends on the required balance between strength, hardness, and machinability for the intended application.

Composition and Microstructure

Chemical Elements

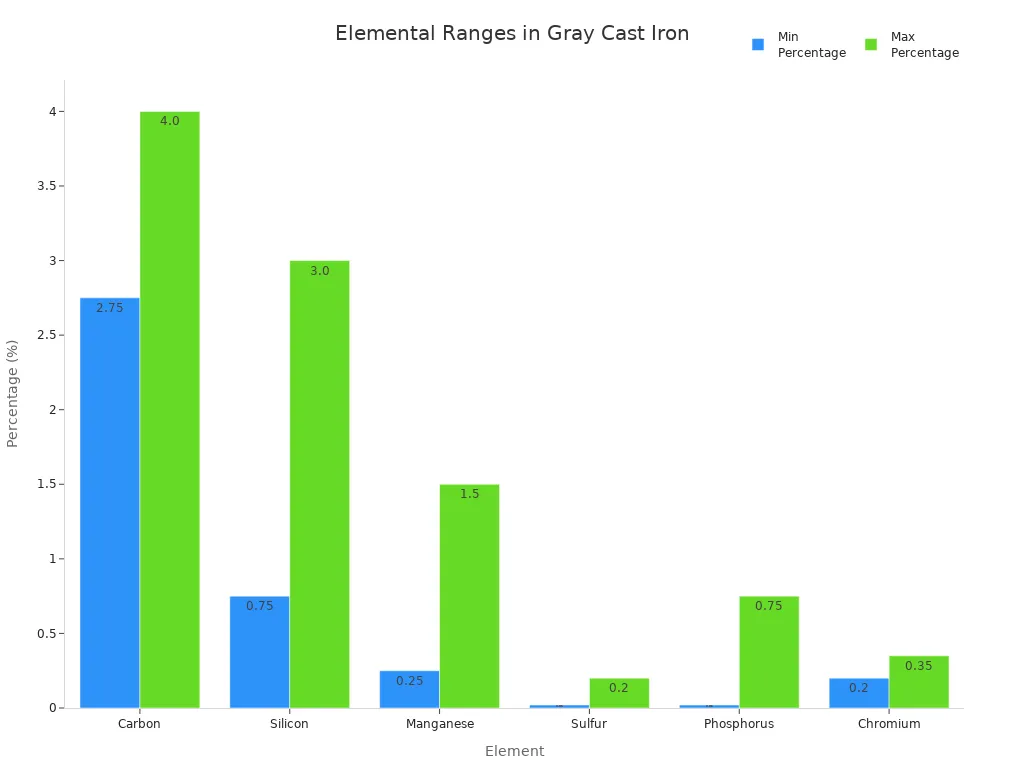

Gray cast iron contains several key elements that determine its properties and performance. Each element plays a specific role in shaping the material’s strength, hardness, and resistance to corrosion.

| Element | Percentage Range | Role in Gray Cast Iron |

|---|---|---|

| Carbon | 2.75 to 4.00 percent | Most important element; affects strength and hardness. |

| Silicon | 0.75 to 3.00 percent | Reduces solubility of carbon in iron; essential for producing gray iron. |

| Manganese | 0.25 to 1.50 percent | Helps form manganese sulfide; necessary for controlling sulfur content. |

| Sulfur | 0.02 to 0.20 percent | Promotes formation of Type A graphite; should be kept low for toughness. |

| Phosphorus | 0.02 to 0.75 percent | High levels are undesirable; affects pressure tightness in applications. |

| Chromium | 0.20 to 0.35 percent | Improves hardness and strength; enhances elevated temperature properties. |

| Molybdenum | N/A | Increases modulus of elasticity; improves elevated temperature properties. |

- Carbon gives gray cast iron its strength and hardness.

- Silicon is essential for forming graphite and reducing carbon solubility. Higher silicon content also improves corrosion resistance by creating a protective pseudo-passive layer on the surface.

- Manganese helps control sulfur and supports the formation of graphite.

- Sulfur should remain low to maintain toughness.

- Phosphorus can affect pressure tightness, so engineers keep its level low.

- Chromium and molybdenum enhance strength, hardness, and performance at high temperatures.

Tip: Adjusting the levels of these elements allows engineers to tailor gray cast iron for specific applications, balancing machinability, strength, and durability.

Graphite Flakes

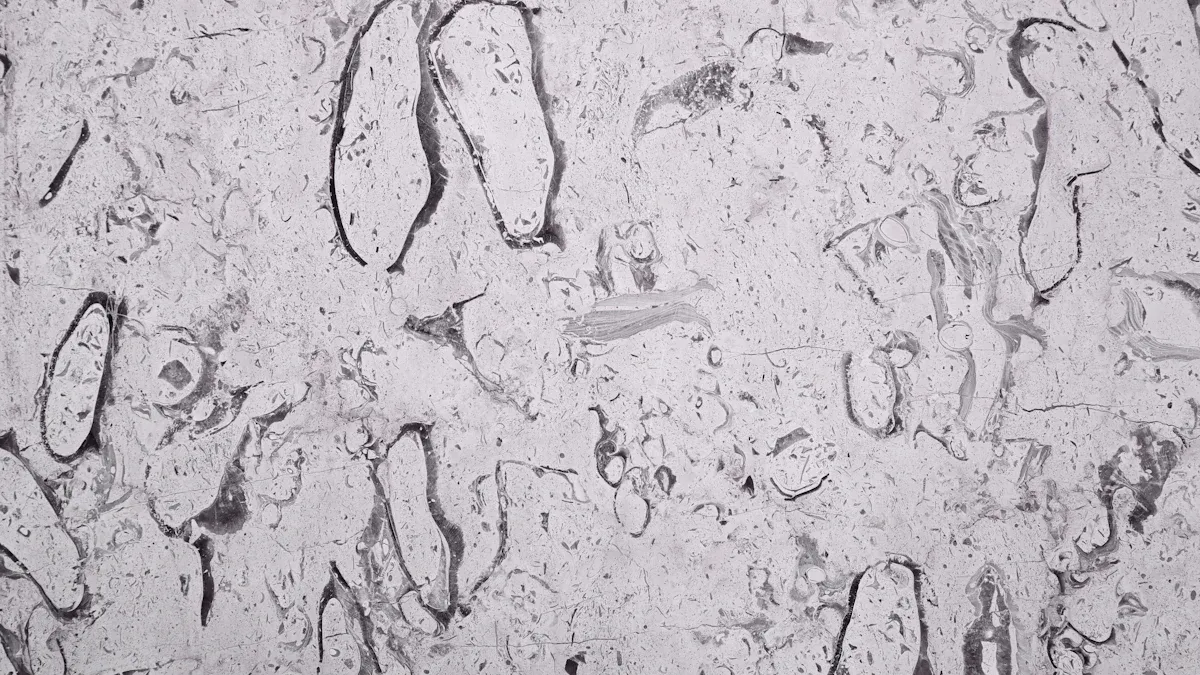

Graphite flakes define the microstructure of gray cast iron. These flakes form during solidification and spread throughout the iron matrix. Their size, shape, and distribution have a direct impact on the material’s properties.

| Parameter | Value Range |

|---|---|

| Flake Size | 5.61 mm to 9.41 mm |

| Volume of Flake Graphite | 13.50% to 18.10% |

| Graphite Structure | Isotropic |

Microscopists use nital etching to reveal the graphite flakes in gray cast iron. Optical microscopy and advanced techniques like three-dimensional X-ray microscopy (3D-XRM) help visualize the flake shapes. Electron Backscattered Diffraction (EBSD) in Scanning Electron Microscopy (SEM) measures the orientation of the flakes.

Mechanical Impact

The graphite flakes interrupt the continuity of the iron matrix. This structure lowers tensile strength but improves machinability and vibration damping. The flakes act as natural lubricants, making gray cast iron easy to cut and shape. However, the presence of flakes also creates points where cracks can start, which limits the material’s ductility.

Fracture Appearance

When gray cast iron breaks, the fracture surface appears gray and dull. The graphite flakes scatter light, giving the material its name. The fracture path follows the flakes, resulting in a rough, uneven surface. This unique appearance helps engineers quickly identify gray cast iron in broken components.

Note: The size and distribution of graphite flakes not only affect mechanical properties but also influence how the material looks after fracture. This visual cue is a practical tool for quality control and material identification.

Production Process

Melting and Alloying

Gray cast iron production begins with melting pig iron, which comes from iron ore processed in a blast furnace. Foundries often re-melt pig iron with scrap iron, steel, limestone, and carbon (coke) to create the desired mixture. Modern facilities use electric induction furnaces or electric arc furnaces for precise temperature control. Some foundries still use cupola furnaces for larger batches. After melting, workers transfer the molten iron to a holding furnace or ladle for further adjustments.

Operators carefully control the carbon and silicon content in the molten iron. These elements determine the final properties of gray cast iron. The cooling rate during solidification also affects the formation of graphite flakes, which influence strength and machinability. The flake graphite structure, along with the metal matrix, shapes the material’s vibration damping and wear resistance.

Tip: Adjusting carbon and silicon levels during melting helps engineers achieve the right balance of hardness, strength, and machinability for each application.

- The flake graphite structure impacts vibration damping.

- Carbon and silicon content control strength and machinability.

- Cooling rate affects graphite flake formation.

Casting Methods

Foundries use several casting methods to shape gray cast iron into finished products. Each method offers unique advantages for different applications.

| Casting Method | Advantages |

|---|---|

| Sand Casting | Inexpensive, versatile, suitable for small and large components, but lower surface finish and dimensional accuracy. |

| Die Casting | Excellent detail and dimensional accuracy, good surface finish, but more expensive due to high die costs. |

| Shell Mold Casting | Improved dimensional accuracy and surface finish compared to sand casting. |

| Lost Foam Casting | Can produce complex shapes with excellent dimensional accuracy without cores or parting lines. |

| Centrifugal Casting | Produces uniform thickness and density, ideal for cylindrical parts like pipes. |

Sand casting remains the most common casting process for gray cast iron. It works well for both small and large components, though it may not provide the highest surface finish. Die casting and shell mold casting offer better accuracy and surface quality, but they cost more. Lost foam casting allows for complex shapes without the need for cores. Centrifugal casting creates parts with uniform thickness, making it ideal for pipes and rings.

Quality Control

Quality control ensures that gray cast iron meets strict standards for performance and reliability. Foundries use several measures to check the properties and integrity of each casting.

| Quality Control Measure | Description |

|---|---|

| Dimensional Measurement | Ensures castings’ dimensions, tolerances, and geometric features meet specified requirements. |

| Non-Destructive Testing (NDT) | Detects defects without damaging the casting using methods like visual inspection and ultrasonic testing. |

| Mechanical Testing | Assesses mechanical properties such as tensile strength and hardness. |

| Chemical Analysis | Determines the composition of the cast iron to ensure it meets specifications. |

| Pressure Testing | Detects leaks and weak points by subjecting the casting to pressurized fluid. |

| Hardness Profiling | Measures hardness at various points to identify variations in material properties. |

| Visual and Surface Inspection | Identifies surface defects to ensure quality and appearance meet specifications. |

Operators perform dimensional measurements to confirm that castings match design specifications. Non-destructive testing methods, such as ultrasonic inspection, help detect internal flaws without damaging the product. Mechanical testing checks tensile strength and hardness. Chemical analysis verifies the composition of the cast iron. Pressure testing identifies leaks and weak points. Hardness profiling and visual inspections ensure consistent quality and appearance.

Note: Consistent quality control helps manufacturers deliver reliable gray cast iron products for demanding engineering applications.

Properties of Gray Cast Iron

Strength

Gray cast iron offers a balance between strength and cost. Engineers often select this material for components that do not require extreme tensile strength. The graphite flakes in the microstructure interrupt the iron matrix, which lowers tensile strength but improves other properties. The typical tensile strength for gray cast iron ranges from 20,000 to 60,000 psi. Ductile iron, in comparison, starts at a minimum of 60,000 psi. The table below shows how gray cast iron compares to ductile iron:

| Type of Cast Iron | Tensile Strength (psi) |

|---|---|

| Gray Cast Iron | 20,000 – 60,000 |

| Ductile Iron | Minimum 60,000 |

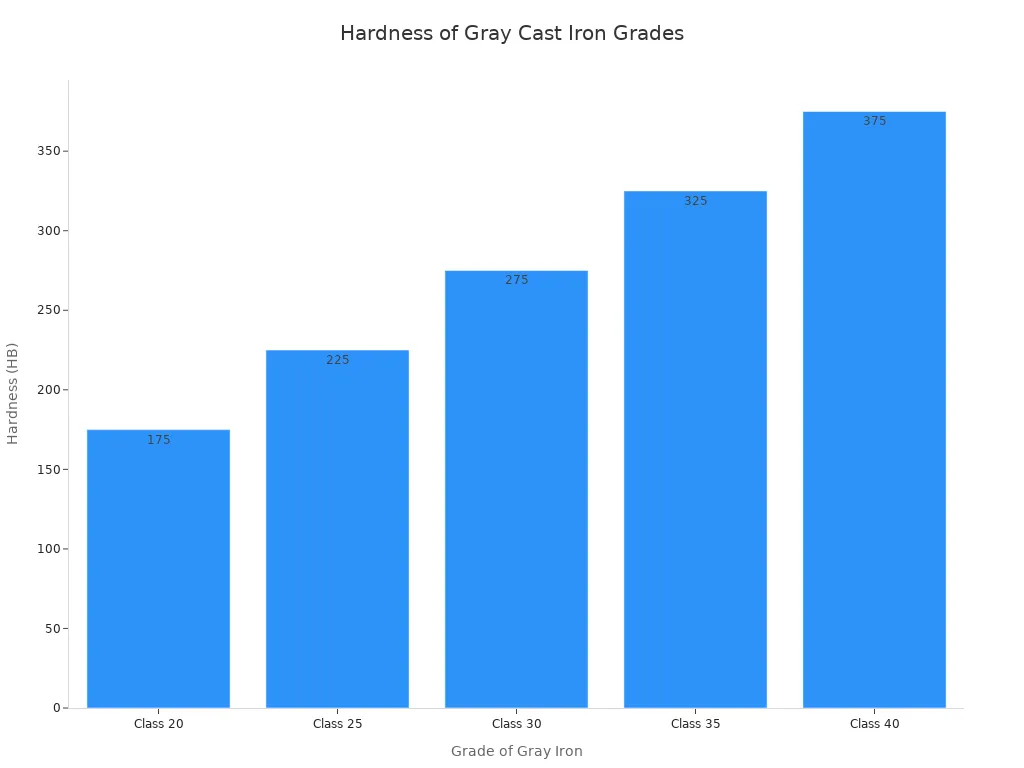

Hardness also varies by grade. The following table lists typical hardness values for different grades of gray cast iron:

| Grade of Gray Iron | Typical Hardness Range |

|---|---|

| Class 20 | 150 – 200 HB |

| Class 25 | 200 – 250 HB |

| Class 30 | 250 – 300 HB |

| Class 35 | 300 – 350 HB |

| Class 40 | 350 – 400 HB |

Engineers should consider both tensile strength and hardness when selecting gray cast iron for load-bearing applications.

Thermal Conductivity

Gray cast iron stands out for its high thermal conductivity. The graphite flakes in the microstructure allow heat to transfer efficiently through the material. This property makes gray cast iron ideal for engine blocks, cookware, and other products that require rapid heat dissipation. The specific heat capacity of gray cast iron also supports stable temperature control in industrial settings.

- Gray iron has a higher thermal conductivity than ductile iron.

- The high thermal conductivity of gray iron is attributed to heat transfer through graphite flakes.

The combination of high thermal conductivity and specific heat capacity helps prevent overheating and supports consistent performance in demanding environments.

Machinability

Machinability is a key advantage of gray cast iron in manufacturing. The unique microstructure, especially the presence of graphite flakes, makes the material easy to cut and shape. The graphite acts as a chip breaker, which reduces cutting forces and improves surface finish. This lubricating effect also lowers tool wear and increases productivity.

- The unique microstructure of gray cast iron contributes to its machinability.

- The presence of graphite acts as a chip breaker, reducing cutting forces.

- Graphite provides a lubricating effect, improving surface finish.

- The size and distribution of graphite flakes are critical for machinability.

- Excellent machinability allows for efficient cutting and shaping processes.

- Lower cutting forces are required when machining gray cast iron due to graphite.

- This leads to reduced tool wear and increased productivity.

- Variability in microstructure can affect machining performance.

Manufacturers benefit from lower costs and reduced machining time when using gray cast iron for complex parts.

Wear Resistance

Gray cast iron demonstrates notable wear resistance, which makes it a preferred material for many industrial applications. The wear resistance of this material comes from its unique microstructure. Graphite flakes, embedded within the iron matrix, play a significant role in how the material responds to friction and abrasion. These flakes act as solid lubricants, reducing direct metal-to-metal contact during operation.

Hardness stands as a primary indicator of wear resistance in gray cast iron. Engineers often select gray cast iron for moving mechanical parts that face continuous friction, such as gears, brake rotors, and grinding machinery. The high hardness of this material allows it to withstand abrasive forces, high temperatures, and heavy impacts. This durability ensures that components maintain their shape and function over long periods, even in harsh environments.

- Hardness is a key indicator of strength and wear resistance in gray cast iron.

- The properties of gray cast iron depend on the shape, distribution, and amount of graphite present.

- Enhanced hardness contributes to better machinability and overall performance in mechanical applications.

The graphite structure not only improves machinability but also helps the material resist surface wear. When two surfaces slide against each other, the graphite flakes provide a lubricating effect. This reduces the rate of material loss and extends the service life of components. As a result, gray cast iron finds use in pump housings, engine blocks, and machine tool beds, where both wear resistance and vibration damping are essential.

Despite its advantages, gray cast iron can experience specific failure modes in industrial service. These failures often result from a combination of mechanical stress and casting defects. Some of the most common failure modes include:

- Spiral cracking, which often appears in medium-sized pipes as a circumferential crack that spirals down the pipe.

- Wedge splitting, typically seen in large-diameter pipes under high bending loads, where a wedge-shaped section splits off.

- Casting defects, such as corrosion pitting and manufacturing flaws, can also lead to premature failures.

Other casting-related issues may include:

- Pores

- Hot and cold cracks

- Shrinkage and porosity

- Slag holes and iron beans

- Sand inclusion

- Deformation

Engineers must consider these potential failure modes when designing components. Proper quality control during production helps minimize defects and ensures consistent wear resistance. Selecting the right grade of gray cast iron, with an optimal balance of hardness and graphite content, further enhances durability.

Note: Regular inspection and maintenance of gray cast iron components can help detect early signs of wear or failure, reducing the risk of unexpected breakdowns in critical machinery.

Gray cast iron’s combination of hardness, self-lubricating graphite, and cost-effectiveness makes it a reliable choice for applications where wear resistance is a top priority.

Common Uses for Gray Cast Iron

Gray cast iron serves as a foundation for many essential products in modern engineering. Its unique combination of thermal conductivity, vibration damping, and machinability makes it a preferred choice for a wide range of applications. The following table highlights the most common product types manufactured from gray cast iron and their key characteristics:

| Product Type | Key Characteristics | Common Applications |

|---|---|---|

| Flake Graphite | Excellent thermal conductivity, vibration damping, ease of machining, cost-effective | Automotive, industrial applications |

| Nodular Graphite | Superior tensile strength, enhanced ductility, toughness | High-stress components (crankshafts, gears) |

| Compacted Graphite | High strength, thermal conductivity, machinability | Automotive engine components |

Grey Cast Iron Products

Engineers and manufacturers rely on gray cast iron for several critical products. Each product leverages the material’s strengths to meet demanding operational requirements.

Pump Casting

Gray cast iron is widely used for pump housings and impellers. The material withstands high speeds and fluid forces, making it ideal for moving liquids in industrial settings. Its sturdy nature suppresses vibration and reduces noise, which ensures reliable pump operation. Precision casting allows for complex shapes, improving pump efficiency and fluid flow. Corrosion resistance extends the service life of pumps, especially when handling aggressive fluids. The following features make gray cast iron a top choice for pump casting:

- Withstands high mechanical stress and fluid forces.

- Suppresses vibration and reduces operational noise.

- Enables complex, efficient designs through precision casting.

- Offers corrosion resistance for long-term reliability.

- Provides cost-effective production for large-scale use.

Motor Casting

Motor casting often uses gray cast iron for its excellent machinability and thermal stability. The material maintains its mechanical properties across a wide temperature range, making it suitable for electric motors and internal combustion engine cylinder blocks. Its vibration damping properties help protect sensitive motor components from damage. Manufacturers choose gray cast iron for motor housings because it supports intricate designs and ensures consistent performance.

Cast Iron Pulley

Cast iron pulleys benefit from the wear resistance and strength of gray cast iron. The material handles continuous friction and heavy loads without significant wear. Its self-lubricating graphite flakes reduce maintenance needs and extend service life. Engineers select gray cast iron for pulleys in industrial machinery parts, conveyor systems, and automotive applications due to its durability and cost-effectiveness.

Impeller Casting

Impeller casting relies on gray cast iron for its ability to withstand high rotational speeds and abrasive environments. The material’s high tensile strength and resistance to wear ensure long-term performance. Gray cast iron impellers maintain their shape and efficiency even under demanding conditions. The corrosion resistance of the material is essential for impellers used in pumps that handle aggressive or corrosive fluids.

Note: The combination of machinability, strength, and corrosion resistance makes gray cast iron a practical solution for complex, high-performance components.

Industrial Applications

Gray cast iron finds use in a broad range of industries. Its properties support both heavy-duty and everyday applications. The table below summarizes the largest consumer industries and their main application areas:

| Industry | Main Application Areas |

|---|---|

| Automotive | Engine blocks, cylinder heads, disc brake rotors (strength and heat resistance) |

| Industrial Machinery | Machine bases, frames, tooling equipment (vibration damping and wear resistance) |

| Piping & Fittings | Water, sewage, gas pipelines, valve bodies (corrosion resistance and durability) |

| Construction Equipment | Excavators, loaders, heavy machinery components (reliability and operational longevity) |

| Consumer Appliances | High-performance stove plates, cast iron cookware, engine housings |

Automotive manufacturers use gray cast iron for internal combustion engine cylinder blocks, cylinder heads, and disc brake rotors. These components require strength, heat resistance, and vibration damping. Industrial machinery parts such as machine bases and frames benefit from the material’s ability to absorb vibrations and resist wear. Piping and fittings, including valve bodies, rely on gray cast iron for corrosion resistance and long-term durability. Construction equipment manufacturers select gray cast iron for components that demand reliability and operational longevity. In consumer appliances, gray cast iron appears in high-performance stove plates and cast iron cookware, where thermal conductivity and durability are essential.

Tip: Gray cast iron’s abundance and ease of production make it a cost-effective choice for manufacturers across multiple industries.

The common uses for gray cast iron reflect its versatility and reliability. Engineers continue to select this material for products that require a balance of strength, machinability, and cost-effectiveness.

Standards and Grades

International Standards

Gray cast iron must meet strict standards to ensure reliable performance in engineering applications. International organizations such as ASTM, ISO, and EN have developed classification systems that help engineers and manufacturers select the right material for each project.

ISO 185:1988 sets out the specifications for gray cast iron. This standard defines the required tensile strength and hardness for different grades. Designers, buyers, and suppliers use ISO 185:1988 as a reference when choosing gray iron castings. The standard helps ensure that castings will perform as expected under real-world conditions.

ASTM standards also play a key role in the classification of gray cast iron. ASTM Grade 30 or 200, for example, categorizes gray cast iron based on tensile strength. Class 40 requires a minimum tensile strength of 40 ksi. These classifications guide engineers in selecting the correct grade for specific uses. ASTM standards require that a representative test bar meets the tensile strength requirements of its class. This process ensures that the material will be suitable for its intended application.

Tip: International standards provide a common language for engineers and manufacturers. They help guarantee that gray cast iron products will meet safety and performance requirements across different regions.

Grade Selection

Selecting the right grade of gray cast iron is essential for achieving the desired performance in any application. Engineers must consider several criteria before making a decision. Each grade offers a unique balance of properties, so understanding these factors helps optimize both function and cost.

The table below summarizes the main criteria for grade selection:

| Criteria | Description |

|---|---|

| Hardness | Choose a grade with the hardness needed for durability and long service life. |

| Wear Resistance | Assess the level of wear resistance required for the operating environment. |

| Thermal Properties | Evaluate thermal conductivity for applications involving heat transfer or dissipation. |

| Machinability | Consider how easily the grade can be machined after casting. |

| Application Requirements | Analyze expected loads, operating temperatures, and environmental conditions. |

| Performance vs Cost | Balance the need for high performance with budget constraints and long-term costs. |

| Manufacturing Processes | Ensure the selected grade matches available manufacturing capabilities and processes. |

Engineers often start by analyzing the expected loads and operating temperatures. They then match these requirements to the hardness and wear resistance of available grades. For parts that need efficient heat dissipation, thermal properties become a priority. Machinability is important for components that require precise post-casting operations.

Performance must be balanced with cost. Higher grades may offer better durability, but they can increase production expenses. Engineers should also confirm that the chosen grade aligns with the manufacturing processes available at their facility.

Selecting the correct grade of gray cast iron ensures that components will deliver reliable performance, meet safety standards, and remain cost-effective throughout their service life.

Grey Cast Iron Cost

Cost Factors

Several factors influence the cost of grey cast iron for B2B buyers. Companies often see price differences based on order size, product specifications, and supplier characteristics. The following points highlight the main cost drivers:

- Volume and Minimum Order Quantity (MOQ): Large orders usually result in lower unit prices because of economies of scale. Buyers who purchase in bulk often receive discounts.

- Specifications and Customization: Custom shapes, sizes, or unique alloy compositions can increase production costs. Standard products tend to be more affordable.

- Quality and Certifications: Higher quality materials and compliance with international standards may raise costs. However, these factors ensure reliability and performance in demanding applications.

- Supplier Factors: The reputation, production capacity, and location of the supplier can affect pricing. Suppliers with advanced facilities or strong track records may charge more.

- Incoterms: Shipping and logistics terms, such as FOB or CIF, determine which party pays for transportation and insurance. These terms can impact the final delivered cost.

Buyers should review these factors when planning large-scale purchases to optimize both price and quality.

Comparison

When comparing the cost of different cast iron types, grey cast iron stands out for its affordability. The table below summarizes how raw material and processing expenses differ among common cast irons:

| Type of Iron | Raw Material Cost Comparison | Processing Expenses |

|---|---|---|

| Gray Cast Iron | Lower than Ductile Iron | Generally lower due to ease of machining |

| Ductile Iron | 10-20% more than Gray Iron | Potentially lower overall part costs due to design flexibility |

| White Cast Iron | N/A | N/A |

Grey cast iron typically costs less to produce than ductile iron. Its simple composition and easy machinability reduce both material and processing expenses. Ductile iron, while offering higher strength, requires more expensive alloys and additional processing steps. White cast iron is less common for general engineering uses and does not offer the same cost advantages.

Cost-Effectiveness

Grey cast iron offers strong cost-effectiveness for industrial applications. Manufacturers can produce castings quickly and at a lower price compared to many alternatives. The material’s high compressive strength and excellent vibration damping make it suitable for heavy-duty parts. Its ease of machining and welding further reduces production time and labor costs. Grey cast iron also experiences less shrinkage during cooling, which helps maintain dimensional accuracy and reduces waste.

- Production costs remain relatively low, making it a preferred choice for large-scale projects.

- Castings can be manufactured rapidly, supporting tight project timelines.

- The material’s properties support long service life, reducing replacement and maintenance expenses.

- Compared to steel castings, grey cast iron costs about 20% more, but it remains competitive with steel forgings and heat-treated steels.

- Titanium alloys, while strong, are much more expensive and less practical for most industrial uses.

For companies seeking a balance between performance and budget, grey cast iron provides a practical and reliable solution.

Gray cast iron delivers reliable performance for modern engineering. Its cost-effectiveness, strength, machinability, and damping capacity make it a top choice for industrial applications. The table below highlights key advantages for B2B buyers:

| Advantage | Description |

|---|---|

| Cost-Effectiveness | Low production costs for large-scale projects. |

| Strength & Durability | Handles heavy loads and wear. |

| Machinability | Supports precise, complex components. |

| Damping Capacity | Reduces vibration and noise. |

| Thermal Conductivity | Manages heat efficiently. |

| Wear Resistance | Extends service life of parts. |

Compliance with international standards ensures consistent quality and global compatibility. Recent innovations, such as thin-wall casting and improved quality control, enhance the value of grey cast iron in engineering. Customers seeking dependable grey iron castings can contact SHENGRONG for practical solutions and expert support.

FAQ

What makes gray cast iron different from ductile iron?

Gray cast iron contains graphite flakes, while ductile iron has graphite nodules. The flakes give gray cast iron better vibration damping and machinability. Ductile iron provides higher tensile strength and improved ductility.

Can gray cast iron be welded?

Welding gray cast iron is possible, but it requires special techniques. Preheating and slow cooling help prevent cracking. Most engineers prefer mechanical joining methods for reliability.

Is gray cast iron suitable for high-temperature applications?

Gray cast iron performs well in moderate heat. The material handles engine blocks and cookware. For extreme temperatures, engineers select alloys with added chromium or molybdenum.

How does gray cast iron resist corrosion?

Gray cast iron resists corrosion due to its silicon content. The silicon forms a protective layer on the surface. Regular maintenance and coatings improve long-term durability.

What are common defects in gray cast iron castings?

Common defects include pores, cracks, shrinkage, slag holes, and sand inclusion. Quality control measures, such as non-destructive testing, help detect and prevent these issues.

Why do engineers choose gray cast iron for machine bases?

Engineers select gray cast iron for machine bases because it absorbs vibrations. The graphite flakes dampen noise and movement, which improves accuracy and extends equipment life.

Can gray cast iron be recycled?

Gray cast iron is fully recyclable. Foundries melt scrap cast iron and reuse it in new castings. Recycling reduces costs and supports sustainable manufacturing.

What standards apply to gray cast iron?

International standards, such as ISO 185 and ASTM A48, classify gray cast iron grades. These standards specify tensile strength, hardness, and chemical composition for reliable performance.